Motor-driven air conditioning system for automobile

A technology for electric air conditioners and vehicles, applied in air conditioning systems, applications, home appliances, etc., can solve problems such as low energy efficiency of compressors, pollute the environment, and loud noises, and achieve improved power generation efficiency, simple system structure, and high power generation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

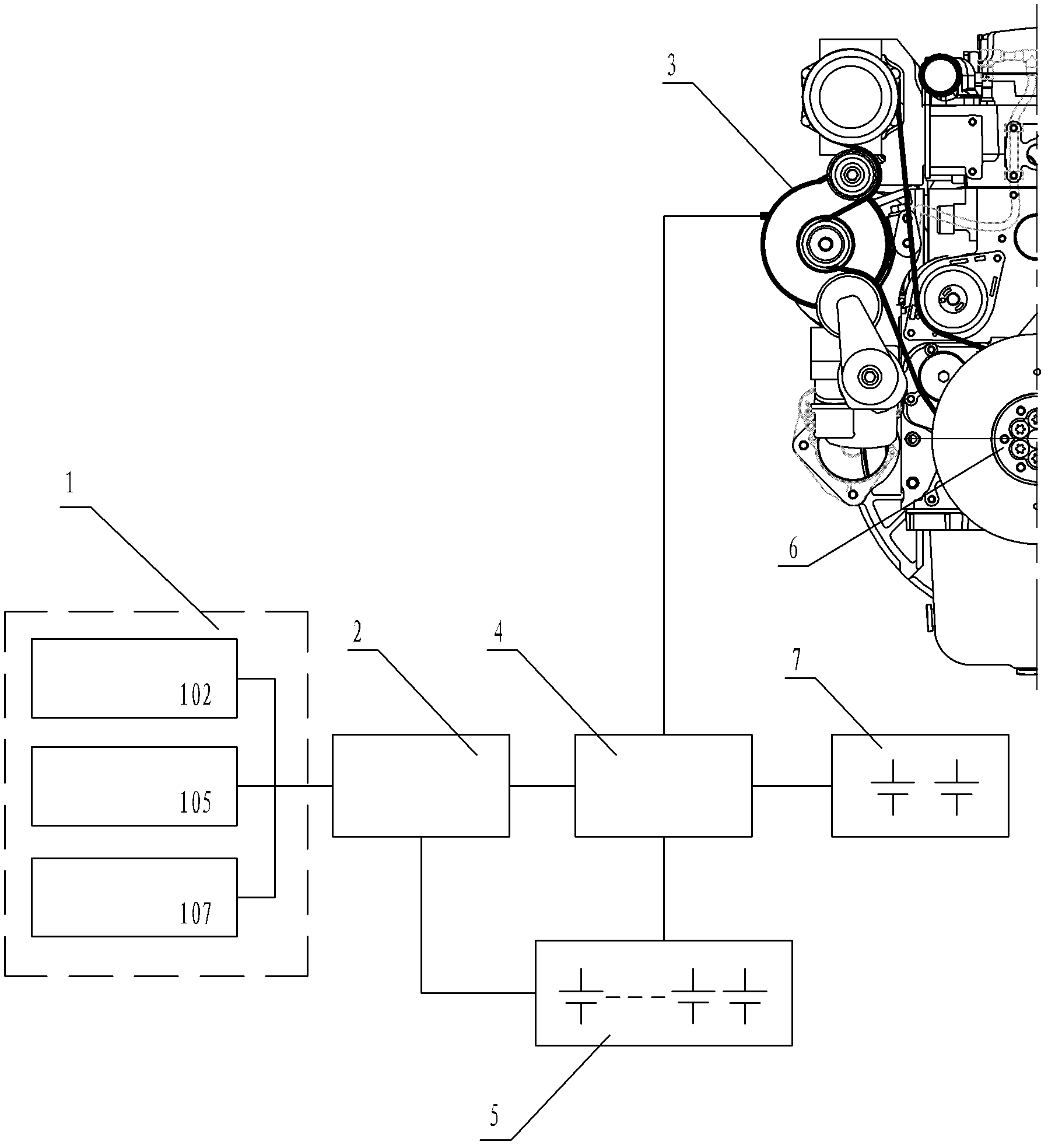

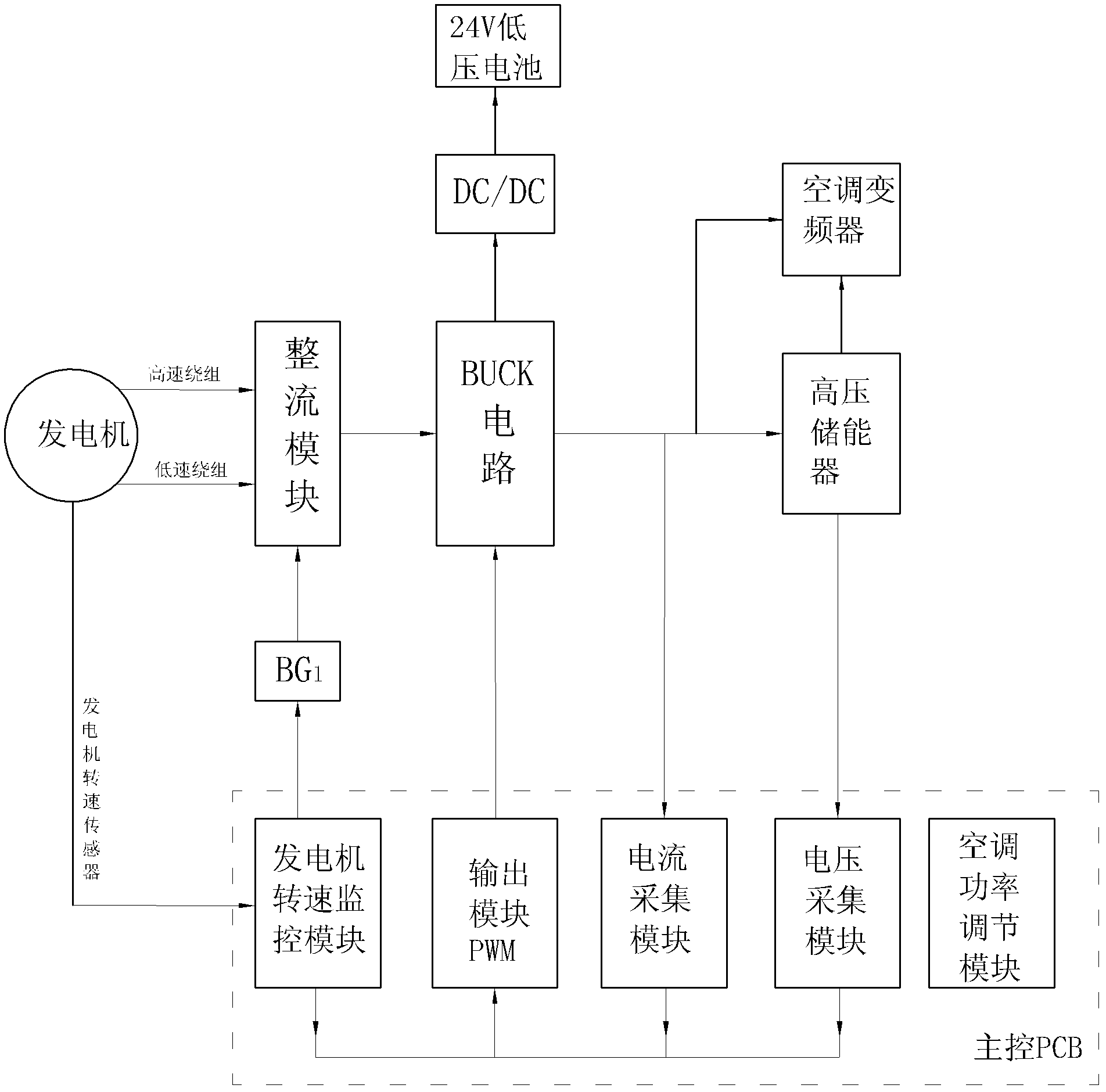

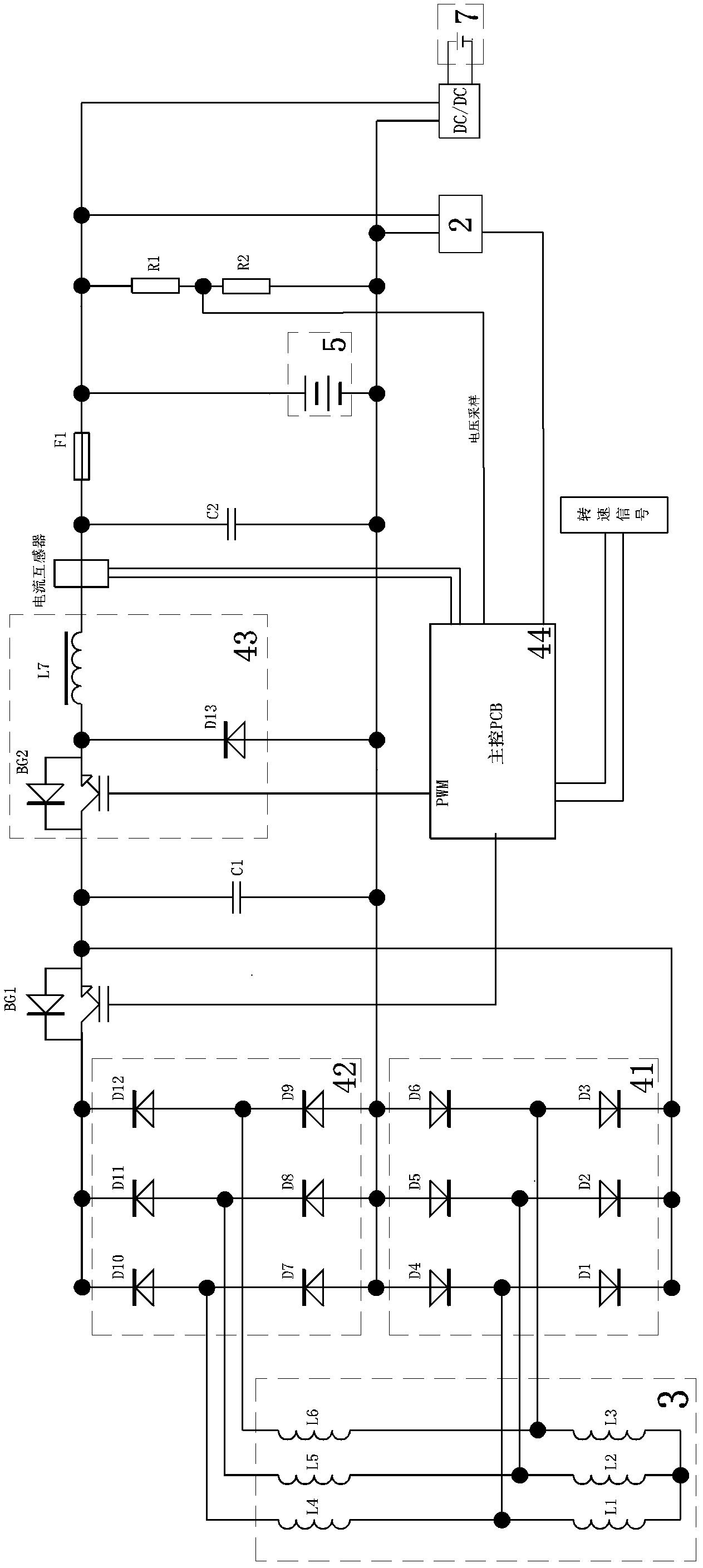

[0029] like figure 1 As shown, the present invention includes an air-conditioning unit 1 , an air-conditioning inverter 2 , a high-voltage generator 3 , a generator controller 4 , and an accumulator 5 .

[0030] The high-voltage generator 3 can be installed at the position of the original air conditioner compressor, and is driven by the crankshaft 6 of the automobile engine through a belt. The high-voltage generator 3 adopts a permanent magnet generator, which greatly improves the power generation efficiency compared with the original low-voltage excitation generator. Compared with the traditional V-belt, the timing belt improves the transmission efficiency.

[0031] The generator 3 is connected to the high-voltage accumulator 5 and the air conditioner inverter 2 through the generator controller 4 . The electricity generated by the generator 3 is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com