Algae-enhanced urea, production method thereof, and purpose thereof

A production method and seaweed technology are applied in the field of seaweed synergistic urea to achieve the effects of firm binding, significant inhibitory effect and complete extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

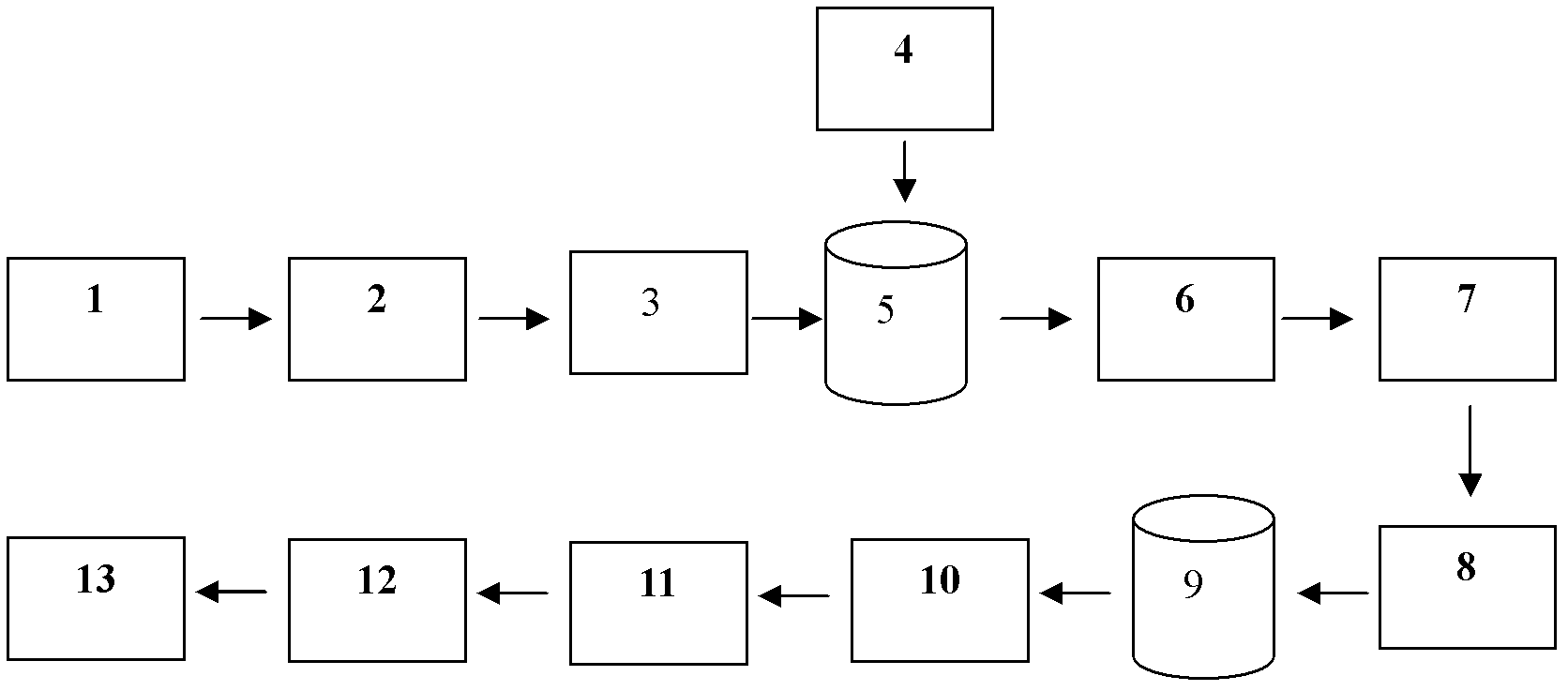

Method used

Image

Examples

Embodiment 1

[0085] Embodiment 1: Preparation of seaweed synergistic urea of the present invention

[0086] The preparation steps are as follows:

[0087] (1) After the kelp raw material is pulverized by crushing equipment, add 100 parts by weight of cornmeal and 30 parts by weight of sugar to 800 parts by weight of natural seaweed raw material powder, and after the mixture is stirred evenly, the water content of the mixture is adjusted to 30% by weight with water , then adjust its pH to 6 with 2N aqueous sodium hydroxide solution, so as to obtain a natural seaweed fermentation material;

[0088] (2) 0.1 weight part of EM flora fermented liquid produced by Jilin Great Wall Agricultural Machinery Biotechnology Co., Ltd. and 0.1 weight part of sucrose are added to 0.5 weight part of water, and after mixing, put into an airtight container and store for 20 hours, so a kind of EM fermentation flora stock solution;

[0089] (3) Use water to dilute the EM fermented flora stock solution prepar...

Embodiment 2

[0093] Embodiment 2: Preparation of seaweed synergistic urea of the present invention

[0094] The preparation steps are as follows:

[0095] (1) After the kelp raw material is pulverized by crushing equipment, add 110 parts by weight of cornmeal and 60 parts by weight of sugar to 1100 parts by weight of natural seaweed raw material powder, and after the mixture is stirred evenly, the water content of the mixture is adjusted to 45% by weight with water , and then adjust its pH to 7 with 2N aqueous sodium hydroxide solution, so as to obtain a natural seaweed fermentation material;

[0096] (2) Add 1.5 parts by weight of EM flora fermented liquid produced by Jilin Great Wall Agricultural Machinery Biotechnology Co., Ltd. and 1.5 parts by weight of sucrose and glucose to 15 parts by weight of water, mix and store in an airtight container for 22 hours, so get A kind of EM fermentation flora stock solution;

[0097] (3) use water to dilute the EM fermented flora stock solution ...

Embodiment 3

[0101] Embodiment 3: Preparation of seaweed synergistic urea of the present invention

[0102] The preparation steps are as follows:

[0103] (1) After the wakame raw material is pulverized by a crushing equipment, add 100 parts by weight of cornmeal and 40 parts by weight of sugar to 1000 parts by weight of natural seaweed raw material powder, and after the mixture is stirred evenly, the water content of the mixture is adjusted to 40 by weight with water. %, then its pH is adjusted to 7 with 4N potassium hydroxide aqueous solution, so that a kind of natural seaweed fermentation material is obtained;

[0104] (2) Add 1.0 parts by weight of Jilin Great Wall Agricultural Machinery Biotechnology Co., Ltd.'s EM flora fermented liquid and 1.0 parts by weight of glucose to 10 parts by weight of water, mix and store in an airtight container for 28 hours, so you get a EM fermentation flora stock solution;

[0105] (3) Use water to dilute the EM fermentation flora stock solution pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com