H2S corrosion resistant ground gathering system corrosion inhibitor and preparation method thereof

A technology of gathering and transportation system and corrosion inhibitor, which is applied in the field of corrosion inhibitor of ground gathering and transportation system and the protection of metal materials, can solve the problems of short validity period, accelerated corrosion, unpleasant smell, etc., and achieves less dosage and corrosion inhibition efficiency. High, easy and fast production results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

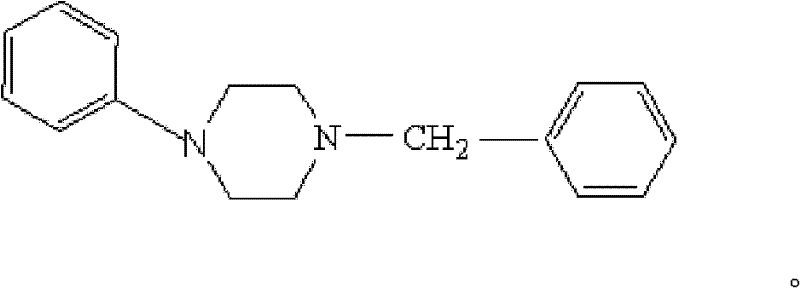

[0021] The preparation of the corrosion inhibitor is divided into two steps: the first step is the synthesis of the main agent N-benzyl-N'-phenylpiperazine, and the second step is the preparation of the corrosion inhibitor.

[0022] Pour N-phenylpiperazine and benzyl chloride into a three-necked flask at a molar ratio of 1.3:1, stir and mix evenly, heat up to 170°C, and keep warm for 8 hours to obtain N-benzyl-N'-phenylpiper Zinc.

[0023] Then the mass percentage is 40% of N-benzyl-N'-phenylpiperazine, 7% of methoxypropylamine, 7% of hydroxyethylene diphosphoric acid, 7% of monomethylamine, 7% of trimethyl Amine, 8% octylphenol polyoxyethylene ether, and 24% dimethylformamide are mixed and stirred evenly to prepare a H 2 S Corrosion inhibitor for surface gathering pipeline corrosion, code name TG530-Z I.

[0024] In order to test the corrosion inhibitor - TG530-Z I against H 2 The protective effect of S corrosion was evaluated by using the high temperature and high pressur...

Embodiment 2

[0035] Pour N-phenylpiperazine and benzyl chloride into a three-necked flask at a molar ratio of 1.3:1, stir and mix evenly, heat up to 140°C, and keep warm for 8 hours; then add 20% N-benzyl Base-N'-phenylpiperazine, 10% methoxypropylamine, 7.5% hydroxyethylene diphosphate, 7% dimethylamine, 7% trimethylamine, 7% octylphenol polyoxyethylene Ether, 10% dimethylformamide, and 31.5% methanol are mixed and stirred evenly to prepare a H 2 S Corrosion inhibitor for surface gathering pipeline corrosion, code name TG530-Z II.

[0036] Through the high temperature and high pressure test, simulate the environment of Table 1 and Table 2 working conditions in Example 1, under the condition that the test cycle is 7 days, when the corrosion inhibitor-TG530-Z II dosage is 100mg / L, its corrosion rate It is 0.0831mm / a, and the corrosion inhibition rate reaches 90.82%.

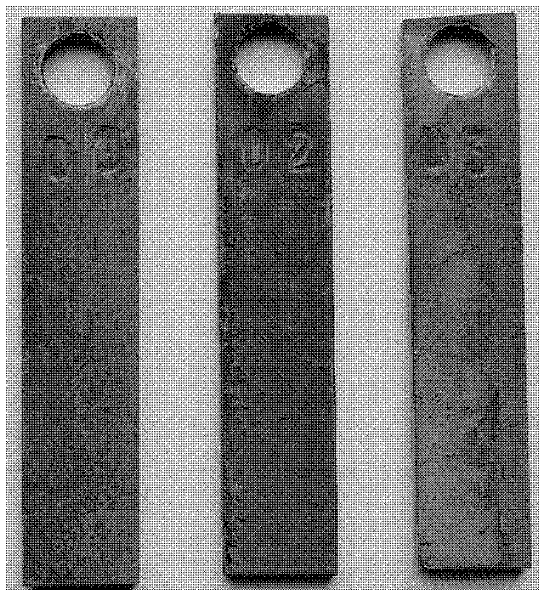

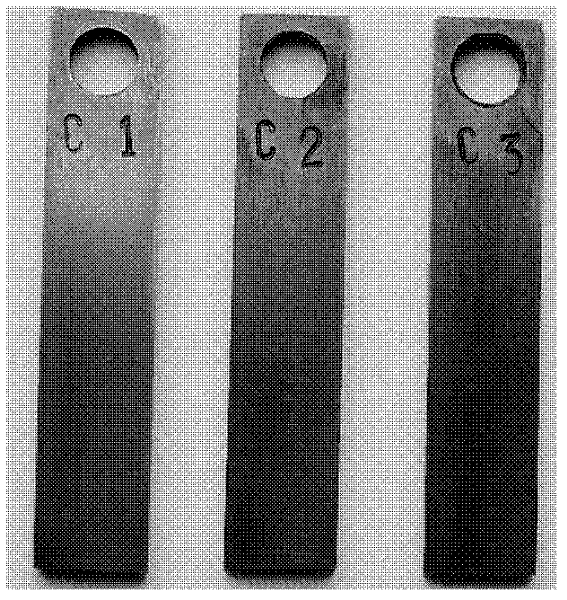

[0037] Macro photo of specimen corrosion figure 1 , figure 2 Shown: Through comparison, it can be seen that the corrosi...

Embodiment 3

[0039] First, the preparation of N-benzyl-N'-phenylpiperazine is carried out. Pour N-phenylpiperazine and benzyl chloride into a three-neck flask at a molar ratio of 1.3:1, stir and mix evenly, raise the temperature to 140°C, and keep the reaction for 8 hours.

[0040] Then, 40% of N-benzyl-N'-phenylpiperazine, 10% of methoxypropylamine, 7% of hydroxyethylene diphosphoric acid, 7% of monomethylamine, 7% of Ethylene oxide condensate, 10% dimethylformamide, and 19% methanol are mixed and stirred evenly to obtain a H 2 S Corrosion inhibitor for ground gathering pipeline corrosion, code name TG530-Z III.

[0041] Through the high temperature and high pressure simulation test, the corrosion rate of the coupon sample added with the corrosion inhibitor-TG530-Z III is shown in Table 4.

[0042] Table 4 Corrosion rate under different corrosion inhibitor dosage

[0043] Corrosion inhibitor dosage, mg / L

Corrosion rate, mm / a

Corrosion inhibition rate, %

0

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com