Planar spiral inductor with wide-narrow-alternatingly line width and space

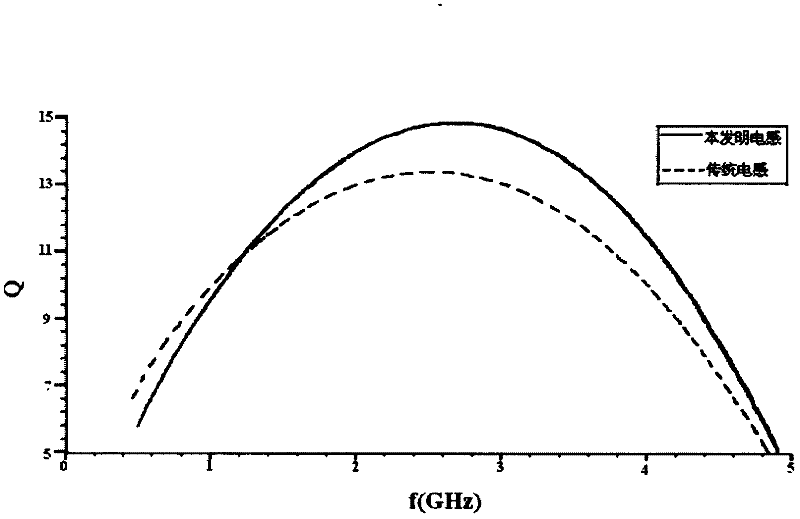

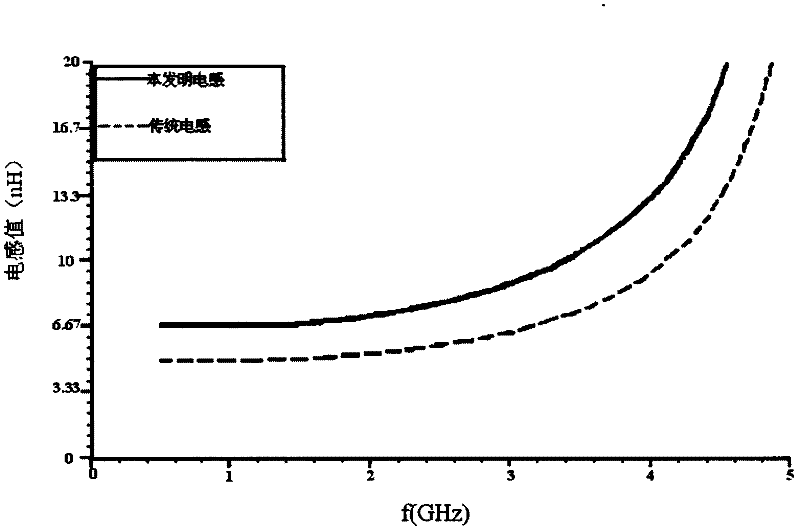

A planar spiral and spiral inductance technology, applied in the field of electronics, can solve the problems of a single change in the metal wire spacing and line width of the spiral inductance, reduce the mutual inductance of the spiral inductance coil, and the inductance value is not significantly improved, etc. Improve the inductance Q value and overcome the effect of the inductance Q value being too low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

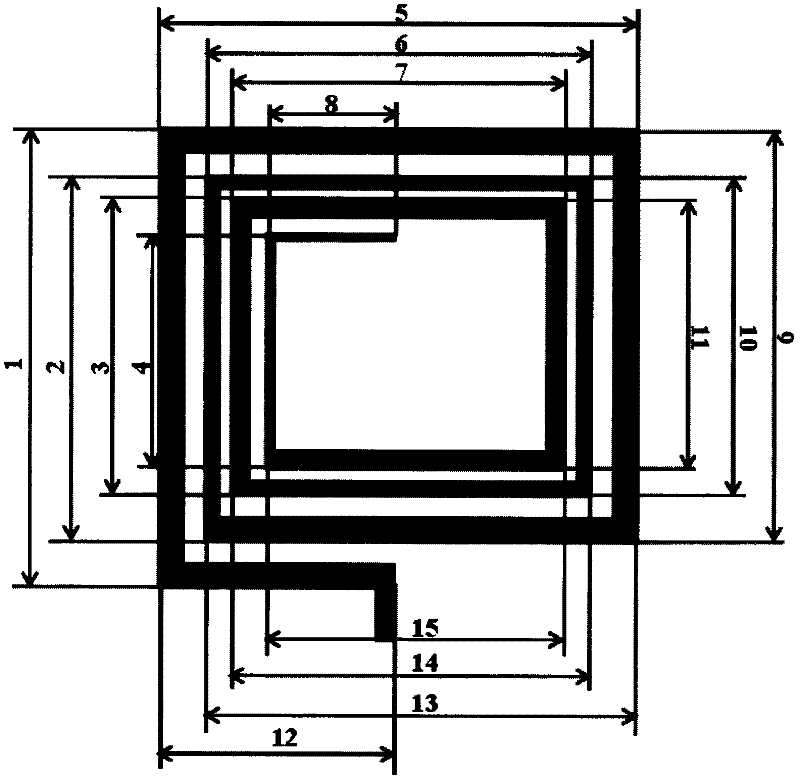

[0022] figure 1 The shown planar spiral inductor with alternating line width and spacing structure includes a silicon substrate, an insulating layer, a bottom metal layer of the planar spiral inductor, through holes, and a metal layer of the planar spiral inductor. A layer of 1 μm thick oxide is grown on a 450 μm thick silicon base to form an insulating layer, a layer of 10 nm thick titanium gold film is sputtered on the insulating layer, and a 500 nm thick metal film is plated on the surface of the titanium gold film, etched Metal film, forming the bottom metal layer of the spiral inductor, depositing a 900nm thick oxide on the bottom metal layer of the spiral inductor to form an insulating layer, etching the insulating layer to form a through hole, and plating a 2μm thick metal film on the insulating layer, selectively Etching forms the spiral inductor met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com