Optical control integrated on-chip inductor

A technology of inductance and chip formation, applied in the direction of inductors, variable inductors, circuits, etc., can solve problems such as high noise level, poor circuit frequency stability, and reduced inductance quality factor Q

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The manufacturing steps of the light-controlled integrated on-chip inductor are as follows.

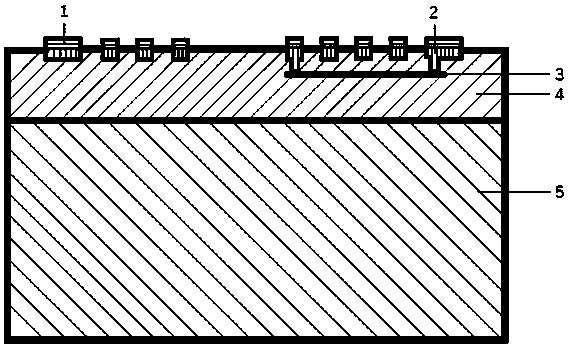

[0013] A silicon wafer is selected, and a silicon dioxide layer is formed on the silicon wafer through a thermal oxidation process.

[0014] The bottom electrode of the inductor coil is made of copper, which is formed on the silicon dioxide layer by electroplating.

[0015] To isolate the bottom and top electrodes, an additional layer of silicon dioxide is deposited on the bottom electrode using plasma-enhanced chemical vapor deposition (PECVD).

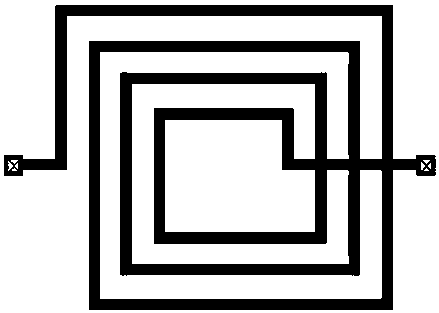

[0016] The production of the inductance coil adopts the damascene process, and the dielectric layer is etched by the reactive ion process to form metal wiring grooves.

[0017] Then, a layer of metal copper that completely fills the groove and covers the entire silicon wafer is electroplated by an electroplating process, and a layer of optomagnetic material is formed on the surface of the copper by deposition.

[0018] Finally, chem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com