Common bombax flower solid beverage and preparation method thereof

A technology of solid beverage and kapok, which is applied in the food field, can solve the problems of increasing the production cost of kapok products, destroying the nutritional content of kapok, and discomfort of consumers, etc., and achieves the effect of bright color, fragrant smell and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

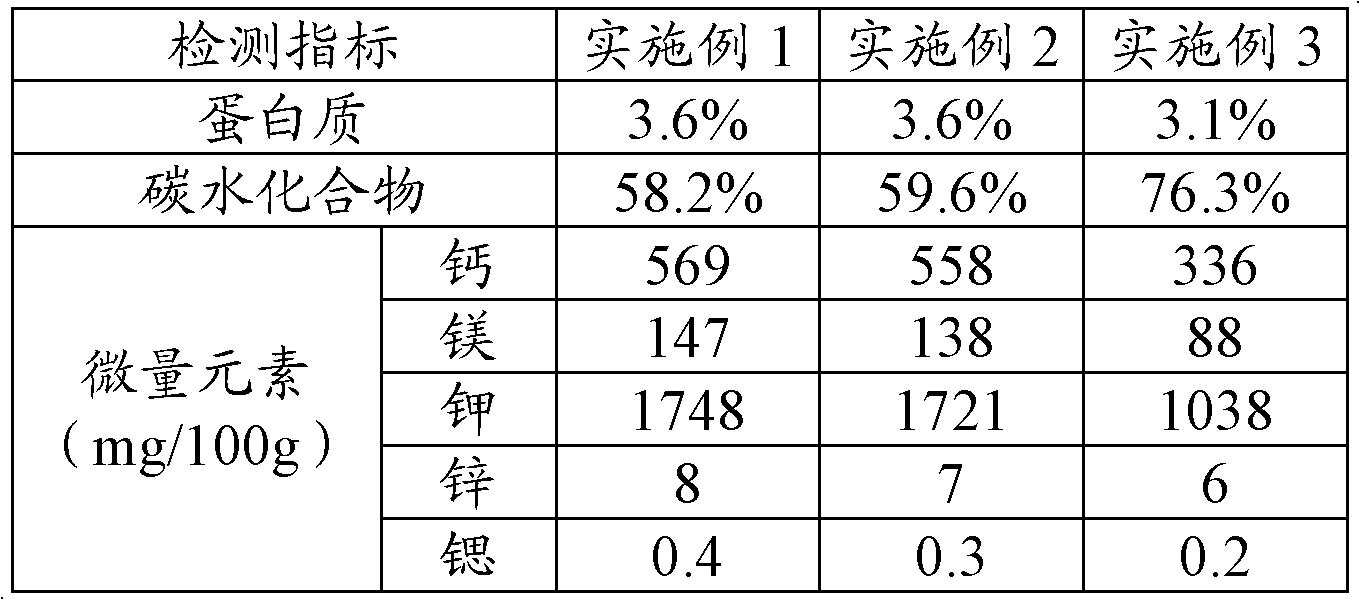

Embodiment 1

[0028] Select fresh kapok without disease spots and pests, wash and place it in an ethanol reflux extraction device and extract it with 70% ethanol reflux for 3 hours, filter it with a 150-mesh screen, and concentrate the filtrate at 60°C under reduced pressure until it has no alcohol smell. Add water to the filter residue after ethanol reflux extraction (one time the quality of the filter residue), stir it with a high-speed shear emulsifier (ZJR-250 / 350L) and filter it with a 150-mesh screen. The concentrate and the filtrate from the second filtration After mixing, add 2% sucrose, 0.2% salt, and 0.2% gum arabic. Use a high-pressure homogenizer to homogenize with a pressure of 22Mpa. The homogeneous solution is dried with a pressure spray dryer. The primary drying is pressure spray drying. The temperature is 160-190°C, the outlet air temperature is 80-90°C, and the feed pressure is 8Mpa. The temperature is 70-90°C, and the powder obtained after drying is the kapok solid drink....

Embodiment 2

[0030] Select fresh kapok without disease spots and pests, wash and place it in an ethanol reflux extraction device and extract it with 70% ethanol reflux for 3 hours, filter it with a 150-mesh screen, and concentrate the filtrate at 60°C under reduced pressure until it has no alcohol smell. Add water to the filter residue after ethanol reflux extraction (one time the quality of the filter residue), stir it with a high-speed shear emulsifier (ZJR-250 / 350L) and filter it with a 150-mesh screen. The concentrate and the filtrate from the second filtration After mixing, add 1% sucrose, 0.1% salt, and 2% gum arabic. Use a high-pressure homogenizer to homogenize with a pressure of 22Mpa. The homogeneous solution is dried with a pressure spray dryer. The primary drying is pressure spray drying. The temperature is 160-190°C, the outlet air temperature is 80-90°C, the feed pressure is 3Mpa, the second stage drying is fixed fluidized bed drying, the inlet air temperature is 70~90°C, the ...

Embodiment 3

[0032] Select fresh kapok without disease spots and pests, wash and place it in an ethanol reflux extraction device and extract it with 70% ethanol reflux for 3 hours, filter it with a 150-mesh screen, and concentrate the filtrate at 60°C under reduced pressure until it has no alcohol smell. Add water to the filter residue after ethanol reflux extraction (one time the quality of the filter residue), stir it with a high-speed shear emulsifier (ZJR-250 / 350L) and filter it with a 150-mesh screen. The concentrate and the filtrate from the second filtration After mixing, add 10% sucrose, 1% salt, and 1% gum arabic. Use a high-pressure homogenizer to homogenize with a pressure of 22Mpa. The homogeneous solution is dried with a pressure spray dryer. The primary drying is pressure spray drying. The temperature is 160-190°C, the outlet air temperature is 80-90°C, and the feed pressure is 12Mpa. The temperature is 70-90°C, and the powder obtained after drying is the kapok solid beverage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com