Sintering flue gas ammonia desulfurization system and process

A technology for ammonia desulfurization and sintering flue gas, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as difficult filtration operations, ammonia escape, and large air consumption, so as to reduce secondary pollution, Reduce the degree of escape and ensure the effect of conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

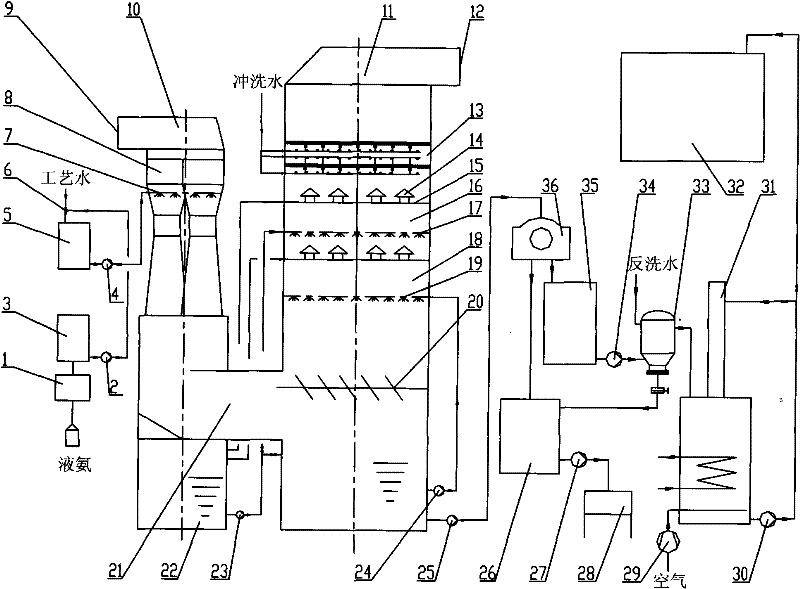

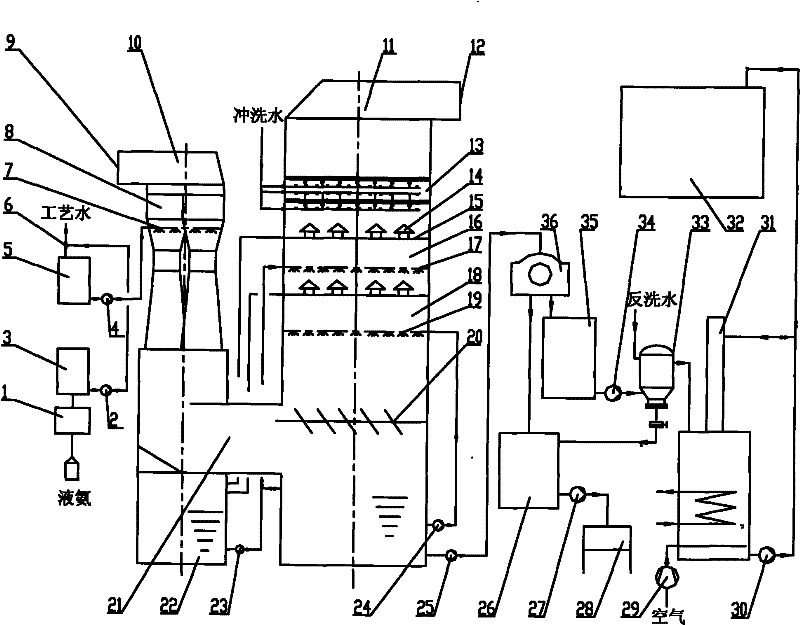

[0024] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention. figure 1 The process water in refers to the deionized water treated by the softening water device. Washing water refers to industrial water for production. Backwash water refers to industrial water that has undergone multi-stage filtration, and the diameter of impurity particles in the water does not exceed 0.3 microns. Circulating water means that in order to rationally use water resources in the industry, the characteristics of high specific heat of water are used as the heat medium carrier. After the cold water absorbs heat and heats up into hot water, the hot water is turned into cold water by means of cooling for recycling.

[0025] Such as figure 1 As shown, the liquid ammonia supply device, that is, the exter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com