Preparation method of modified clinoptilolite ion exchanger

A technology of ion exchanger and clinoptilolite, which is applied in the field of ion exchanger preparation, achieves the effect of less investment, low price and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

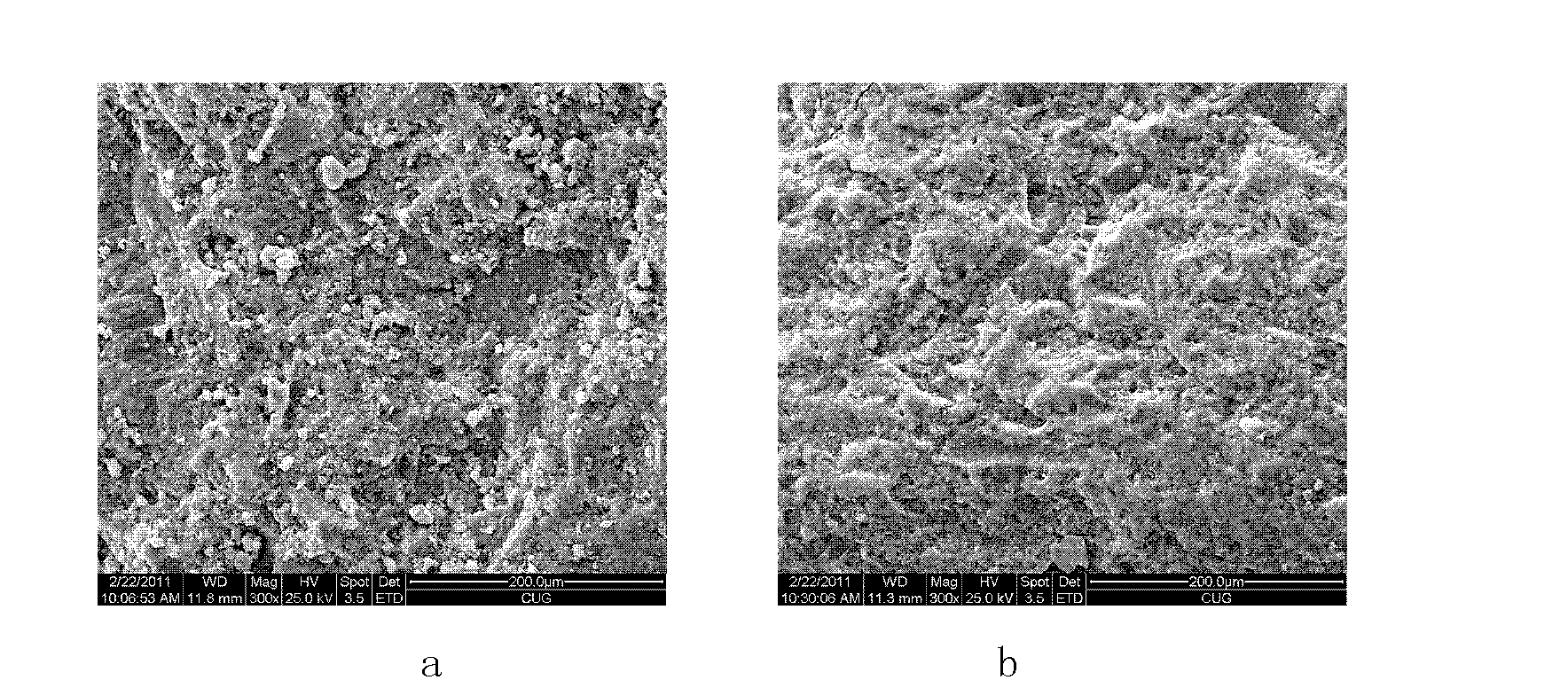

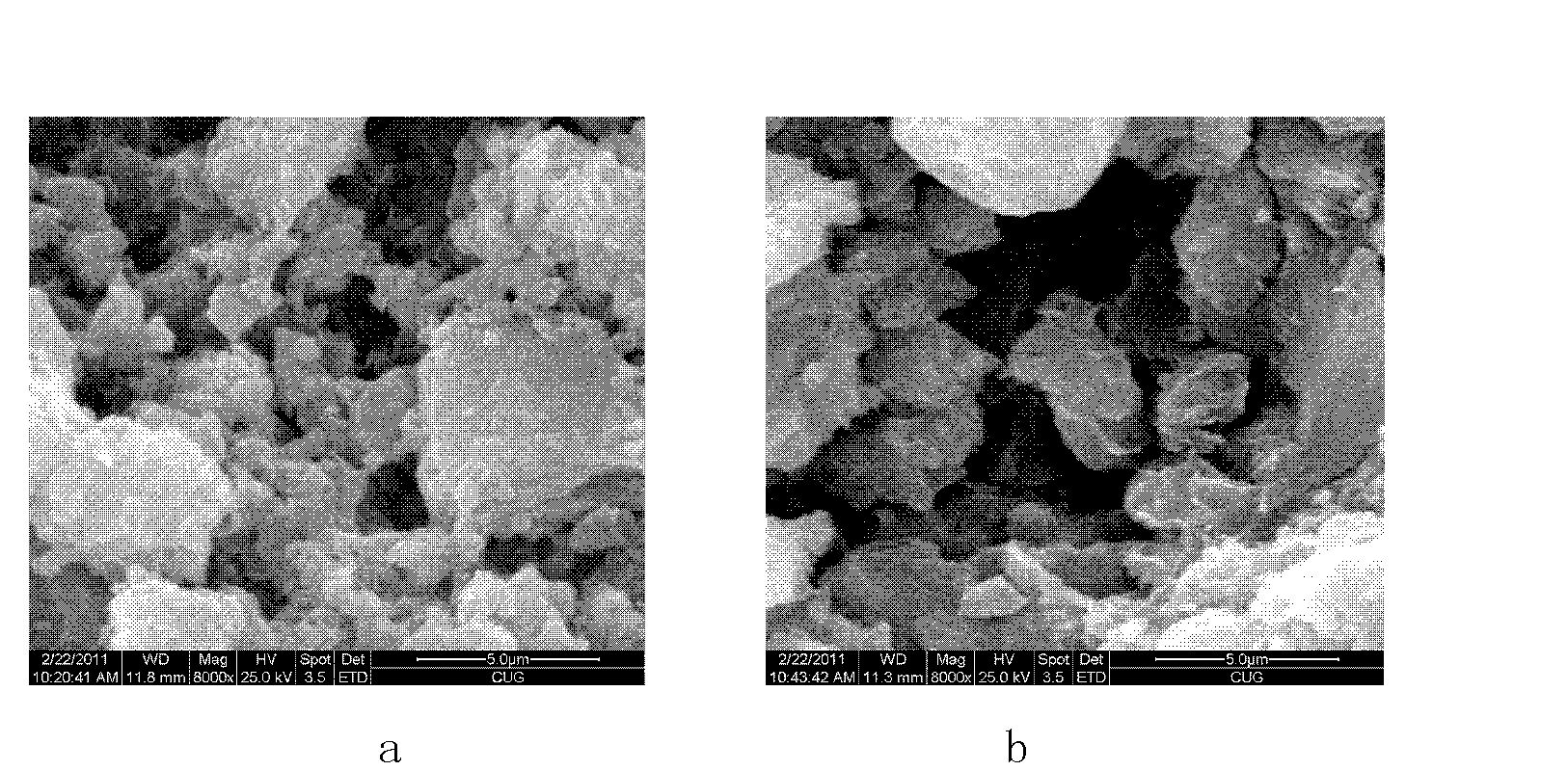

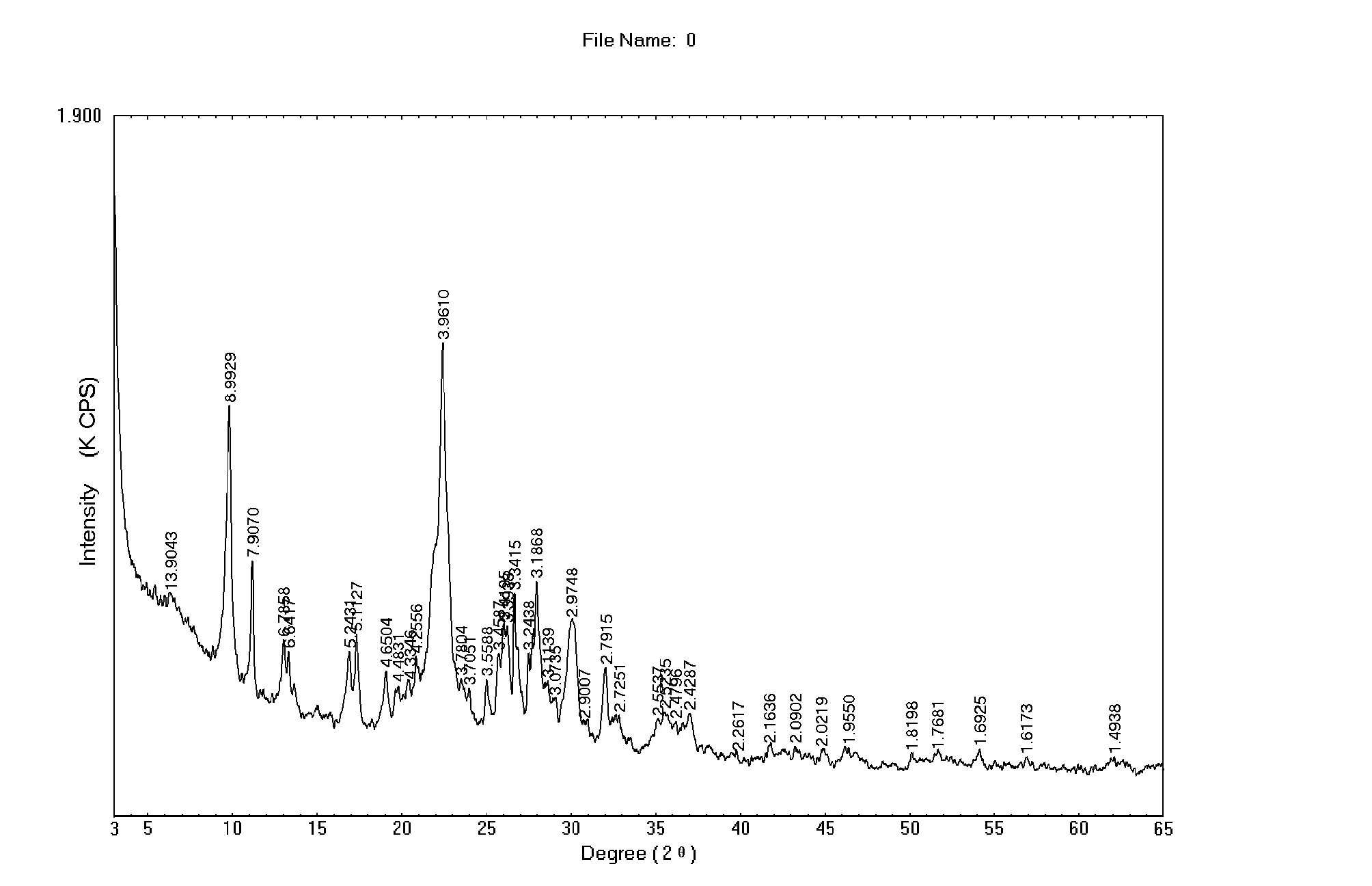

Image

Examples

Embodiment 1

[0042] A kind of preparation method of modified clinoptilolite ion exchanger, it comprises the steps:

[0043] 1) put 10 order natural clinoptilolite into microwave oven, under 800W power, microwave radiation 6min;

[0044] 2) dissolving sodium chloride in ammonia-free water and configuring a sodium chloride solution with a concentration of 1.0 mol / L;

[0045] 3) placing the clinoptilolite obtained in step 1) in a conical flask (glass vessel), mixing the clinoptilolite and the sodium chloride solution uniformly, and modifying it for 4h at 50° C. and a shaking speed of 120 r / min to obtain mixture;

[0046] Wherein, the mass ratio of clinoptilolite and sodium chloride solution is 1: 8;

[0047] 4) the mixture obtained in step 3) is filtered, the filtrate is removed, the solid matter in the mixture is collected, and the solid matter is rinsed with ammonia-free water and dried to obtain the modified clinoptilolite ion exchanger (or modified clinoptilolite). Zeolite ion exchange...

Embodiment 2

[0060] A kind of preparation method of modified clinoptilolite ion exchanger, it comprises the steps:

[0061] 1) put 40 order natural clinoptilolite into microwave oven, under 800W power, microwave radiation 6min;

[0062] 2) dissolving sodium chloride in ammonia-free water to configure a sodium chloride solution with a concentration of 1 mol / L;

[0063] 3) placing the clinoptilolite obtained in step 1) in a conical flask, mixing the clinoptilolite and the sodium chloride solution uniformly, and modifying it for 4h at 50° C. and a shaking rate of 120 r / min to obtain a mixture;

[0064] Wherein, the mass ratio of clinoptilolite and sodium chloride solution is 1: 8;

[0065] 4) filter the mixture obtained in step 3), remove the filtrate, collect the solid matter in the mixture, rinse the solid matter with ammonia-free water and then dry to obtain a modified clinoptilolite ion-exchange adsorbent.

[0066] The initial ammonia nitrogen concentration in the low-concentration ammo...

Embodiment 3

[0068] A kind of preparation method of modified clinoptilolite ion exchanger, it comprises the steps:

[0069] 1) put 80 order natural clinoptilolite into microwave oven, under 800W power, microwave radiation 6min;

[0070] 2) dissolving sodium chloride in ammonia-free water and configuring a sodium chloride solution with a concentration of 1.0 mol / L;

[0071] 3) placing the clinoptilolite obtained in step 1) in a conical flask, mixing the clinoptilolite and the sodium chloride solution uniformly, and modifying it for 4h at 50° C. and a shaking rate of 120 r / min to obtain a mixture;

[0072] Wherein, the mass ratio of clinoptilolite and sodium chloride solution is 1: 8;

[0073] 4) filter the mixture obtained in step 3), remove the filtrate, collect the solid matter in the mixture, rinse the solid matter with ammonia-free water, and then dry it at the bottom to obtain a modified clinoptilolite ion-exchange adsorbent.

[0074] The initial ammonia nitrogen concentration in the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com