Enhanced electrokinetic remediation method of heavy metal contaminated soil

A technology of polluted soil and electric remediation, applied in the restoration of polluted soil and other directions, can solve the problems of difficult dissolution of heavy metals and insufficient removal rate, and achieve the effects of shortening remediation time, improving removal efficiency, and high-efficiency removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] The preparation of the permeable reaction composite electrode of the present invention and the method for using it to carry out electrokinetic restoration of heavy metal polluted soil comprise the following steps:

[0071] (1) Fabrication of composite electrodes

[0072] Fe 0 : Powder with particle size of 10, 50, 100, 200, 400, 600 or 1000 mesh.

[0073] Basic zeolite: basic zeolite with a particle size of 10, 50, 100, 200, 400, 600 or 1000 mesh, the basic zeolite is NaX, NaY, NaM, NaA or NaZSM-5, or KF in Al 2 o 3 ·Basic zeolite formed by loading and modifying on 2NaY composite material. These zeolites have a pH of 8-14, preferably 14.

[0074] Acidic zeolite: Acidic zeolite with a particle size of 10, 50, 100, 200, 400, 600 or 1000 mesh, which is any acidic natural zeolite, or natural zeolite and the above-mentioned basic zeolite after acidification. Taking the phosphoric acidification of clinoptilolite as an example, with 10% by weight of H 3 PO 4 The aqueous...

Embodiment 1

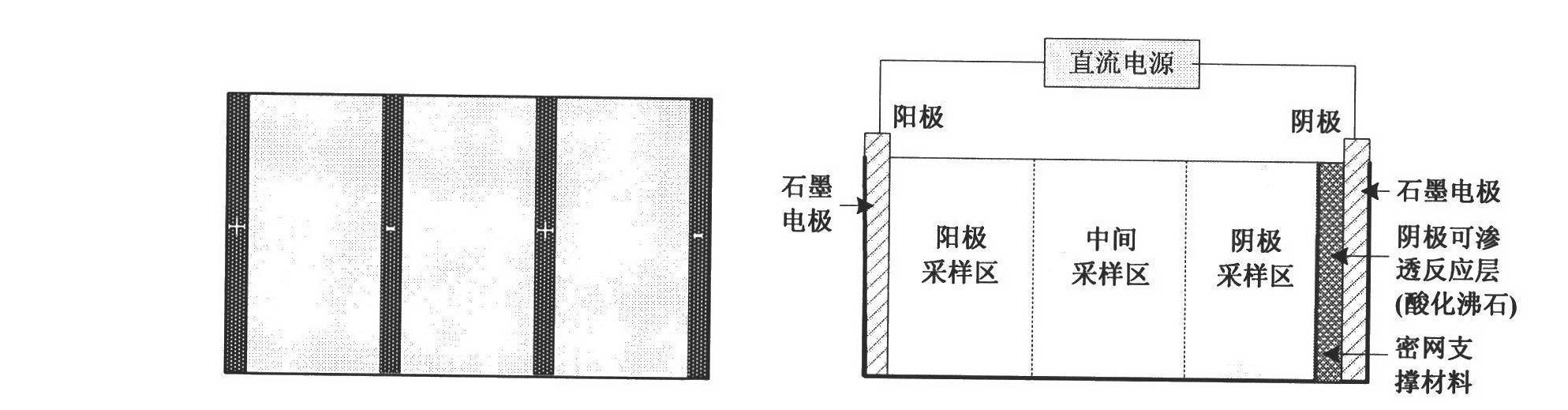

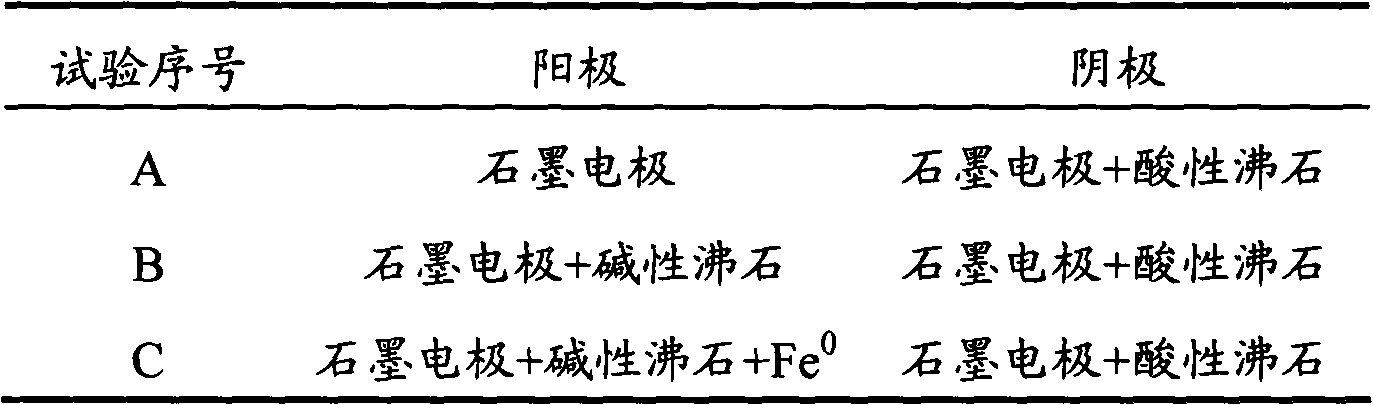

[0088] Embodiment 1: Remediation of chromium-contaminated soil

[0089] A columnar composite electrode is used to electrodynamically remediate chromium-contaminated soil with a chromium (VI) content of 120.1 mg / kg and a moisture content of 30% by mass. Composite electrodes were composed of graphite electrode plates and different permeable reaction materials, and three groups of tests (A, B, and C) were carried out (as shown in Table 1 below). The cathode and anode are respectively high-purity graphite electrodes, and the basic zeolite in the active material is selected from NaX zeolite (initial pH value is 12), and the acid zeolite is formed by acidifying clinoptilolite with 10% phosphoric acid [mass concentration, the same below]. The particle size of the two zeolites is 30 mesh, and the selected Fe 0 The particle size is 300 mesh, these two zeolites and Fe 0 The mass ratio is 1:1. The distance between the cathode and anode electrodes is 20cm.

[0090] Apply a DC voltage ...

Embodiment 2

[0096] According to comprehensive analysis, the removal rates of chromium (VI) in tests A, B, and C all reached more than 90%, while the removal rate of total chromium in test A was much better than that of tests B and C, that is, the removal effect of the anode without pH control was the best. Embodiment 2: the remediation of lead, nickel, cadmium, copper polluted soil

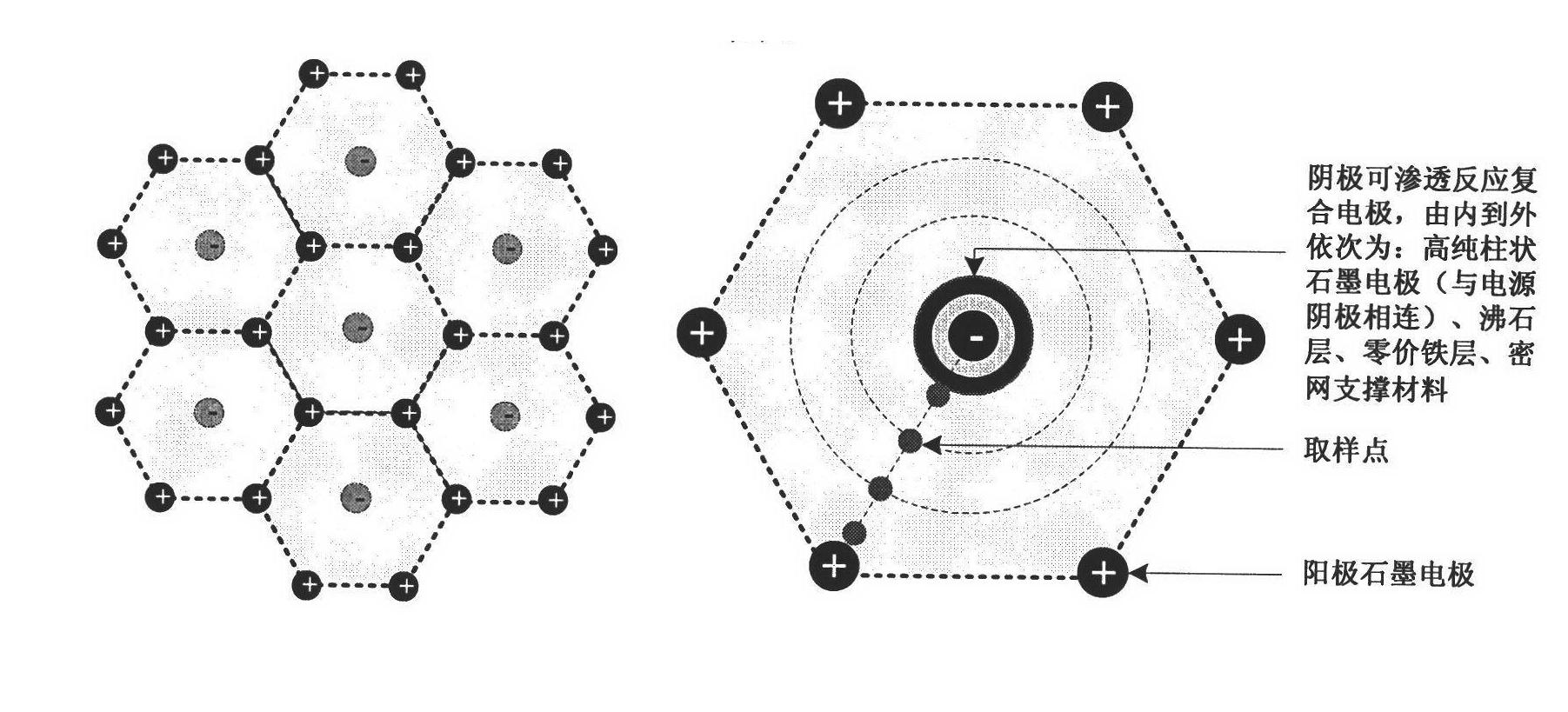

[0097] Insert the columnar composite electrode into the soil with a moisture content of 30% by mass and heavy metal lead, nickel, cadmium, and copper contents of 82.4, 78.9, 85.6, and 86.9 mg / kg in a regular hexagonal matrix. The middle electrode is the cathode, and the cathode 1. The anode distance is 40cm, and a DC voltage with a voltage gradient of 1.5V / cm is applied, and the electric repair is performed for 10 days. The composite electrodes listed in the following table 2 were respectively selected for six groups of tests A, B, C, D, E, and F. In the experiments of groups E and F, the "saturated" composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com