Method for preparing electromagnetic shielding composite material with ferrum-based amorphism/ nanocrystalline strip serving as patch layer

A nanocrystalline strip, iron-based amorphous technology, used in chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of unilateral strip, high cost, burrs, etc. , Solve the problem, the effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

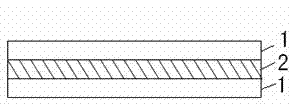

[0023] Step 1: After masticating butyl rubber (IIR) on an open rubber mixer for 3 minutes, add the compounding agent and knead for about 60 minutes to make the composite phase uniformly dispersed in the IIR. The mass ratio is 4:1. Plasticizing rubber and white carbon black are mixed to make an IIR film with a thickness of 0.1mm;

[0024] Step 2: Composite carbon fiber with the above-mentioned IIR film to form a sandwich structure of IIR film / carbon fiber / IIR film, and vulcanize it in a pressure molding machine. The vulcanization temperature is 165°C, the vulcanization time is 2h, and the vulcanization pressure is 8MPa;

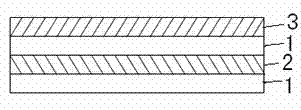

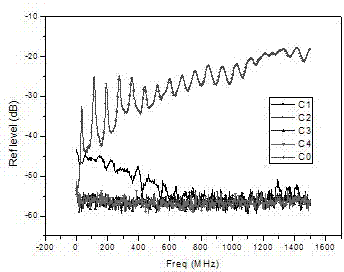

[0025] Step 3: Select Thickness 20 mu m unannealed Fe 78 Si 9 B 13 The iron-based amorphous alloy strip is pasted on the surface of the IIR film / carbon fiber / IIR film sandwich structure prepared in step 2 by dispensing with 502 glue, and the number of pasting layers is 4 layers to obtain a surface conductive electromagnetic shielding composite Material. C...

Embodiment 2

[0027] Step 1: After masticating butyl rubber (IIR) on an open rubber mixer for 10 minutes, add the compounding agent and knead for about 60 minutes to make the composite phase uniformly dispersed in the IIR. The mass ratio is 4:1. Plasticizing rubber and white carbon black are mixed to make an IIR film with a thickness of 0.1 mm;

[0028] Step 2: Composite carbon fiber with the above-mentioned IIR film to form a sandwich structure of IIR film / carbon fiber / IIR film, and vulcanize it in a pressure molding machine. The vulcanization temperature is 165°C, the vulcanization time is 2h, and the vulcanization pressure is 8MPa;

[0029] Step 3: Select Thickness 20 mu m unannealed Fe 78 Si 9 B 13 The iron-based amorphous alloy strip is pasted on the surface of the IIR film / carbon fiber / IIR film sandwich structure prepared in step 2 by dispensing with 502 glue, and the number of pasting layers is 4 layers to obtain a surface conductive electromagnetic shielding composite Material. ...

Embodiment 3

[0031] Step 1: Put the butyl rubber (IIR) on the open rubber mixer for 5 minutes, then add the compounding agent, and mix for about 60 minutes, so that the composite phase is evenly dispersed in the butyl rubber, and the mass ratio is 4:1 , mixing the plasticized rubber and white carbon black to make an IIR film with a thickness of 0.1mm;

[0032] Step 2: Compound the carbon fiber woven fabric with the above-mentioned IIR film to form a sandwich structure of IIR film / carbon fiber / IIR film, and vulcanize it in a pressure molding machine. The vulcanization temperature is 165°C, the vulcanization time is 2 hours, and the vulcanization pressure is 8 MPa;

[0033] Step 3: Select Thickness 20 mu m unannealed Fe 78 Si 9 B 13 The iron-based amorphous alloy strip is pasted on the surface of the IIR film / carbon fiber / IIR film sandwich structure prepared in step 2 by dispensing with 502 glue, and the number of pasting layers is 4 layers to obtain a surface conductive electromagnetic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com