Fertilizer special for super rice and preparation method for fertilizer

A technology of super rice and special fertilizer, applied in application, fertilization equipment, fertilizer mixture, etc., can solve the problems of little effect on the utilization rate of phosphorus and potassium, many times of fertilization of ordinary compound fertilizer, and low utilization rate of ordinary compound fertilizer, etc., to achieve Improve nutrient utilization efficiency, reduce farmers' labor intensity and labor expenditure, and be beneficial to the effect of extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

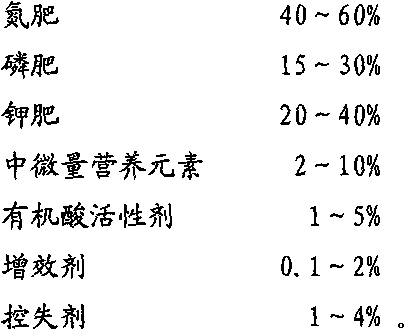

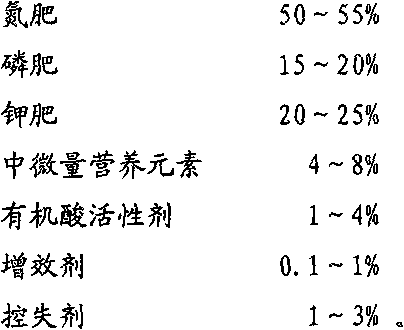

Method used

Image

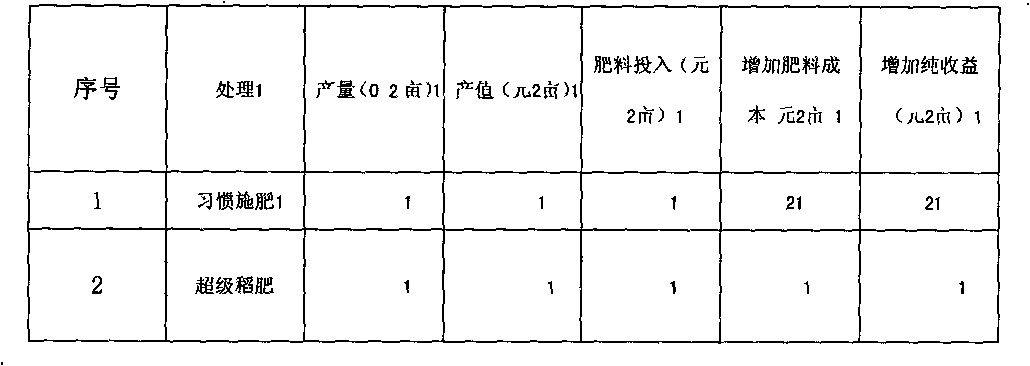

Examples

Embodiment 1

[0025] According to the nutritional characteristics of super rice and the physical and chemical properties of the main paddy field soil in our province, determine the appropriate ratio of nitrogen, phosphorus and potassium. 33% of raw material urea, 20% of ammonium chloride, 18% of monoammonium phosphate, and 21% of potassium chloride are pulverized and mixed into nitrogen, phosphorus and potassium compound fertilizer; the raw materials of medium and micronutrient elements are calcium silicate 2%, magnesium sulfate 1%, 0.8% of zinc sulfate, 0.5% of manganese sulfate, 0.1% of copper sulfate, 0.3% of boric acid, 0.1% of ammonium molybdate, 0.1% of ferrous sulfate and 1% of the mixture of amino acid and citric acid are added to the compound fertilizer of nitrogen, phosphorus and potassium ; Then add 0.1% gibberellin and 2% attapulgite with network structure to the nitrogen, phosphorus and potassium compound fertilizer to make 42% special fertilizer for super rice, that is, to make...

Embodiment 2

[0031] According to the nutritional characteristics of super rice and the physical and chemical properties of the main paddy field soil in our province, determine the appropriate ratio of nitrogen, phosphorus and potassium. 32.5% of raw material urea, 20% of ammonium chloride, 18% of monoammonium phosphate, and 21% of potassium chloride are pulverized and mixed into nitrogen, phosphorus and potassium compound fertilizer; various medium and micronutrient elements such as calcium silicate 2%, magnesium chloride 1%, 0.8% zinc chloride, 0.5% manganese chloride, 0.1% copper chloride, 0.3% boric acid, 0.2% sodium molybdate, 0.5% ferrous chloride and 1% EDTA and citric acid mixture, added to nitrogen phosphorus potassium In the compound fertilizer; then add 0.1% indole acetic acid and 2% attapulgite of network structure to the nitrogen, phosphorus and potassium compound fertilizer to make 40% special fertilizer for super rice, that is, to make effective nutrient content of nitrogen, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com