Method for recovering acrylonitrile butadiene styrene (ABS) plastic galvanized parts

A technology of styrene plastics and recycling methods, which is applied in the direction of plastic recycling, recycling technology, process efficiency improvement, etc., can solve the problems of low purity, low recovery rate, plastic damage, etc., and achieve simple process, convenient use, The effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

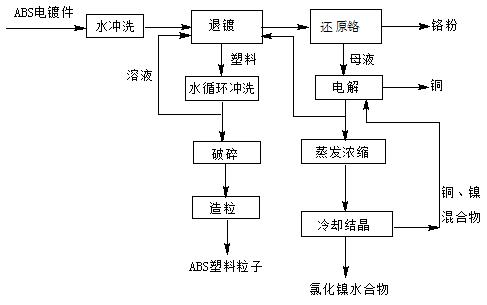

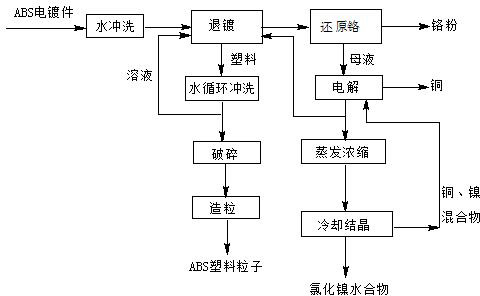

Image

Examples

Embodiment 1

[0022] According to the following steps, the recycling method of ABS plastic electroplating parts is realized, and the process is as follows.

[0023] (1) Put the ABS plastic electroplating parts into the cleaning tank for cleaning, and then crush them to less than 1.0cm with a pulverizer.

[0024] (2) Put the pieces of electroplated parts into the deplating solution containing hydrochloric acid with a mass concentration of 10% and hydrogen peroxide with a mass concentration of 5% at a ratio of liquid to solid of 2:1, and deplate at a temperature of 10°C for 14 hours .

[0025] (3) Rinse the stripped ABS plastic fragments with water in a cleaning tank, crush them again and granulate them to obtain ABS plastic particles, and return the rinsed liquid to step (2).

[0026] (4) The solution after deplating in step (2) flows through the metal sponge and activated carbon successively, and the reduced and precipitated chromium powder is adsorbed on the activated carbon, and the chro...

Embodiment 2

[0031] According to the following steps, the recycling method of ABS plastic electroplating parts is realized, and the process is as follows.

[0032] (1) Put the ABS plastic electroplating parts into the cleaning tank for cleaning, and then crush them to less than 2.0cm with a pulverizer.

[0033] (2) Put the pieces of electroplated parts into the deplating solution containing hydrochloric acid with a mass concentration of 5% and hydrogen peroxide with a mass concentration of 3% according to the ratio of liquid to solid ratio of 3:1, and deplate at 25°C for 4 hours .

[0034] (3) Rinse the stripped ABS plastic fragments with water in a cleaning tank, crush them again and granulate them to obtain ABS plastic particles, and return the rinsed liquid to step (2).

[0035] (4) The solution after deplating in step (2) flows through the metal sponge and activated carbon successively, and the reduced and precipitated chromium powder is adsorbed on the activated carbon, and the chrom...

Embodiment 3

[0040] According to the following steps, the recycling method of ABS plastic electroplating parts is realized, and the process is as follows.

[0041] (1) Put the ABS plastic electroplating parts into the cleaning tank for cleaning, and then crush them to less than 1.0cm with a pulverizer.

[0042] (2) Put the pieces of electroplated parts into the deplating solution containing hydrochloric acid with a mass concentration of 15% and hydrogen peroxide with a mass concentration of 1% at a ratio of liquid to solid of 5:1, and deplate at 40°C for 24 hours .

[0043] (3) Rinse the stripped ABS plastic fragments with water in a cleaning tank, crush them again and granulate them to obtain ABS plastic particles, and return the rinsed liquid to step (2).

[0044] (4) The solution after deplating in step (2) flows through the metal sponge and activated carbon successively, and the reduced and precipitated chromium powder is adsorbed on the activated carbon, and the chromium content in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com