V-Al-N hard coating with nano composite structure and preparation method thereof

A nano-composite, hard coating technology, applied in coating, metal material coating process, ion implantation plating and other directions, can solve the problems of poor coating lubricity, low friction coefficient, low coating hardness, etc. The effect of good quality, low friction coefficient and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

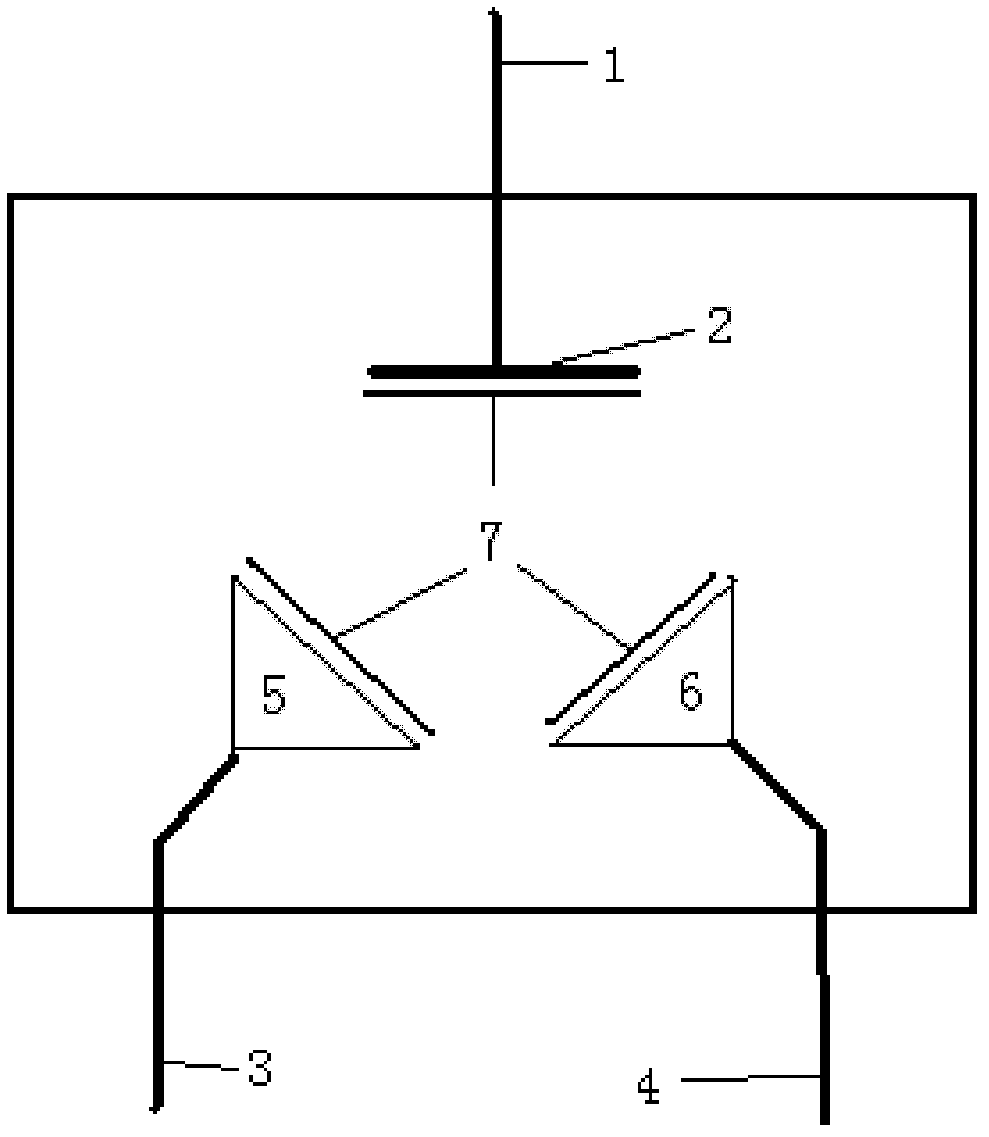

[0038] The preparation method of the V-Al-N hard coating of described nanocomposite structure, comprises the following steps:

[0039] (1) Substrate 2 cleaning:

[0040] First put the substrate 2 into the detergent of model HT1401 produced by Borer Company and ultrasonically clean it at a temperature of 60-70°C for 3-10 minutes, and then put it into the detergent of model HT1233 produced by Borer Company at 50-60°C. Ultrasonic cleaning at ℃ for 3-10 minutes, then ultrasonic cleaning in deionized water at 45-55℃ for 0.5-3 minutes, and finally put the cleaned substrate in a vacuum drying oven at 95-105℃ and bake for 3-10 minutes. Minutes, dried and placed on the rotatable substrate frame in the vacuum chamber;

[0041] Alternatively, first put the substrate 2 into acetone and ultrasonically clean it at a temperature of 60-70°C for 3-10 minutes, then put it into ethanol and ultrasonically clean it at a temperature of 50-60°C for 3-10 minutes, and then clean it at a temperature o...

Embodiment 1

[0049] (1) Substrate cleaning: first put the substrate into the detergent (pH value 12.2) of the model HT1401 produced by Borer Company, and ultrasonically clean it for 5 minutes at a temperature of 65 ° C, and then put it into the detergent produced by Borer Company HT1233 Ultrasonic cleaning at 55°C for 5 minutes in detergent (pH value 9.2), then ultrasonic cleaning in 50°C deionized water for 1 minute, and finally the cleaned substrate was baked in a vacuum oven at 105°C 5 minutes, dry and place on a rotatable substrate rack in a vacuum chamber.

[0050] (2) Deposition coating: in the vacuum chamber, the background pressure of the vacuum chamber is (4.5±0.5)×10 -5 Pa, the Al target is installed on the intermediate frequency cathode, the V target is installed on the DC cathode, the distance between the Al target and the V target and the substrate is 9.2cm, the Al target and the V target are separated from the substrate through the baffle, and the Ar gas is first introduced ...

Embodiment 2

[0053] (1) Substrate cleaning: first put the substrate into the detergent (pH value 12.2) of the model HT1401 produced by Borer Company, and ultrasonically clean it for 5 minutes at a temperature of 65 ° C, and then put it into the detergent produced by Borer Company HT1233 Ultrasonic cleaning at 55°C for 5 minutes in detergent (pH value 9.2), then ultrasonic cleaning in 50°C deionized water for 1 minute, and finally the cleaned substrate was baked in a vacuum oven at 105°C 5 minutes, dry and place on a rotatable substrate rack in a vacuum chamber.

[0054] (2) Deposition coating: in the vacuum chamber, the background pressure of the vacuum chamber is (4.5±0.5)×10 -5 Pa, the Al target is installed on the intermediate frequency cathode, the V target is installed on the DC cathode, the distance between the Al target and the V target and the substrate is 9.2cm, the Al target and the V target are separated from the substrate through the baffle, and the Ar gas is first introduced ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power density | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com