A process for continuous production of electroplated nickel-zinc anti-fingerprint plate

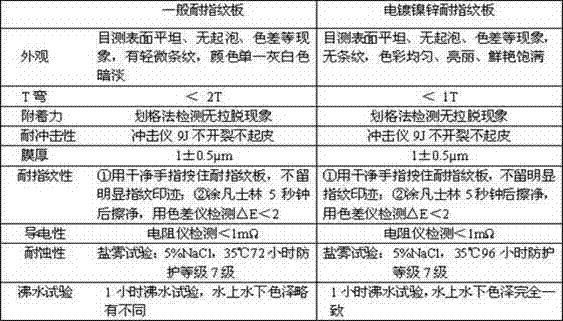

A process method and technology for electroplating nickel, applied in the field of continuous production of electroplated nickel-zinc fingerprint-resistant plates, can solve the problems of difficulty in controlling electroplating polarization reaction, uneven thickness of the surface zinc layer, affecting the uniformity of the coating, etc. Mechanical properties, uniform and fine coating crystals, and the effect of improving the finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

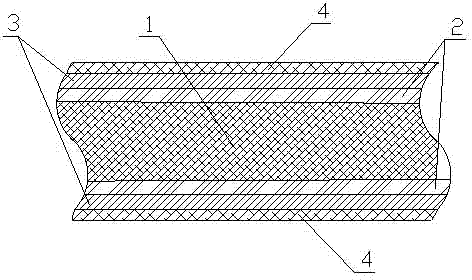

Image

Examples

Embodiment 1

[0023]A process for continuously producing an electroplated nickel-zinc anti-fingerprint plate, the preparation steps comprising:

[0024] (1) After the base steel plate has undergone decoiling, pinching, shearing, pinching, sewing, and flattening processes in sequence on the production line, the base steel plate is degreased and washed with water until the pH value is neutral;

[0025] (2) Immerse the degreasing and water-washed steel plate in a hydrochloric acid solution with a volume ratio of 8% to activate rust removal;

[0026] (3) After the steel plate treated in step (2) is washed with water until the pH value is neutral, alkaline electroplating nickel is performed, and the composition of the alkaline electroplating nickel solution is: nickel sulfate (NiSO 4 ): 15g / L, SF-880U: 50mL / L, SF-880M: 50mL / L, ammonia water: 5mL / L, KOH: 40 g / L; temperature during alkaline nickel plating: 20°C, pH value control At 11, current density: 1A / dm 2 , the alkaline nickel plating time ...

Embodiment 2

[0031] A process for continuously producing an electroplated nickel-zinc anti-fingerprint plate, the preparation steps comprising:

[0032] (1) After the base steel plate has undergone decoiling, pinching, shearing, pinching, sewing, and flattening processes in sequence on the production line, the base steel plate is degreased and washed with water until the pH value is neutral;

[0033] (2) Immerse the degreasing and water-washed steel plate in a hydrochloric acid solution with a volume ratio of 12% to activate rust removal;

[0034] (3) After washing the steel plate treated in step (2) until the pH value is neutral, perform alkaline nickel plating. The composition of the alkaline nickel plating solution is: nickel sulfate 40g / L, SF-880U 100mL / L, SF-880U -880M 100mL / L, ammonia water 20mL / L, KOH 45g / L; the temperature during the alkaline nickel plating process is 60°C, the pH value is controlled at 8, and the current density is 4A / dm 2 , the time of alkaline electroplating ni...

Embodiment 3

[0039] A process for continuously producing an electroplated nickel-zinc anti-fingerprint plate, the preparation steps comprising:

[0040] (1) After the base steel plate has undergone decoiling, pinching, shearing, pinching, sewing, and flattening processes in sequence on the production line, the base steel plate is degreased and washed with water until the pH value is neutral;

[0041] (2) Immerse the degreasing and water-washed steel plate in a hydrochloric acid solution with a volume ratio of 10% to activate rust removal;

[0042] (3) After washing the steel plate treated in step (2) until the pH value is neutral, perform alkaline nickel plating. The composition of the alkaline nickel plating solution is: nickel sulfate 25g / L, SF-880U 80mL / L, SF-880U -880M 80mL / L, ammonia water 10mL / L, KOH 50g / L; the temperature during the alkaline nickel plating process is 40°C, the pH value is controlled at 9, and the current density is 3A / dm 2 , the time of alkaline electroplating nick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com