Method for extracting and observing three-dimensional appearance of non-metallic inclusion in steel in full-scale mode

A technology for non-metallic inclusions and three-dimensional morphology, which is used in the field of non-destructive full-scale extraction and observation of non-metallic inclusions in steel, which can solve the problem that the morphology and size of inclusions are greatly different, the inclusions cannot be maintained, and they are not representative. To solve problems such as sex, to achieve the effect of short cycle, simple method and short processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

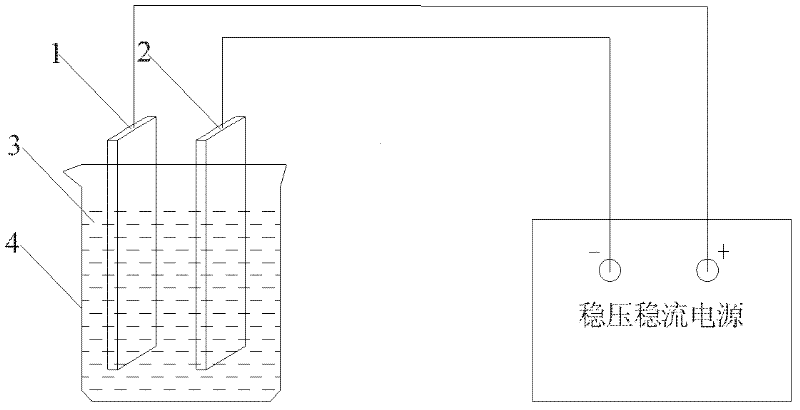

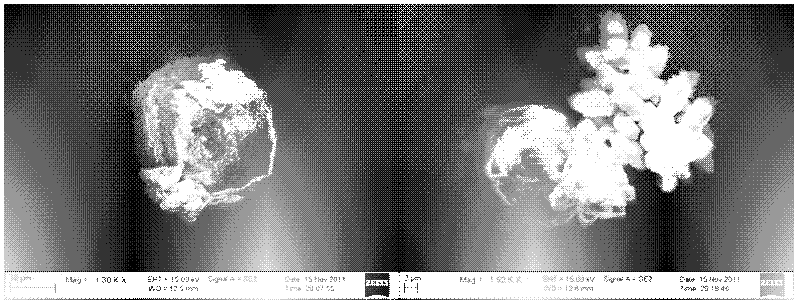

[0037] By adopting the technical scheme of the invention, a certain Al deoxidized B-containing steel is sampled and analyzed. First, process the steel sample taken into a thin plate sample of 120mm×70mm×4mm, and polish each surface of the sample with 800# sandpaper to make the surface smooth; then use ultrasonic cleaning in acetone solution to remove the oil stains on the surface ; Secondly, configure the electrolyte, the proportion of the electrolyte: 1.5% tetramethylammonium chloride, 8% triethanol ammonium, 90.5% is propylene carbonate; the sample plate to be electrolyzed is used as the anode, the stainless steel plate is used as the cathode, and the insulated copper The wire connects the stainless steel plate to the cathode of the power supply, the sample is connected to the anode of the power supply, and the current density is controlled to 0.05A / cm 2 , electrolysis time 24h; after electrolysis, pour the electrolyte and anode mud into a 500ml large beaker, and clean the s...

Embodiment 2

[0041]By adopting the technical scheme of the invention, a certain Si-Al deoxidized Ti-containing steel is sampled and analyzed. First, process the steel sample taken into a thin plate sample of 100mm×50mm×3mm, and polish each surface of the sample with 800# sandpaper to make the surface smooth; then use ultrasonic cleaning in acetone solution to remove oil stains on the surface ; Secondly, configure the electrolyte, the proportion of the electrolyte: 1.0% tetramethylammonium chloride, 5.0% triethanolammonium, 94.0% is propylene carbonate; the sample plate to be electrolyzed is used as the anode, the stainless steel plate is used as the cathode, and the insulated copper The wire connects the stainless steel plate to the cathode of the power supply, the sample is connected to the anode of the power supply, and the current density is controlled to 0.05A / cm 2 , electrolysis time 24h; after electrolysis, pour the electrolyte and anode mud into a 500ml large beaker, and clean the s...

Embodiment 3

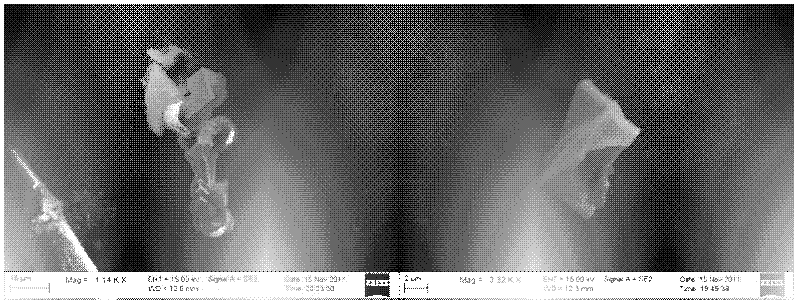

[0045] By adopting the technical solution of the present invention, a certain Al deoxidized steel is sampled and analyzed. First, process the steel sample taken into a thin plate sample of 160mm×90mm×5mm, and polish each surface of the sample with 800# sandpaper to make the surface smooth; then clean the sample plate with ultrasonic waves in acetone solution to remove oil stains on the surface ; Secondly, configure the electrolyte, the proportion of the electrolyte: 3.0% tetramethylammonium chloride, 10.0% triethanolammonium, 87.0% is propylene carbonate; the sample plate to be electrolyzed is used as the anode, the stainless steel plate is used as the cathode, and the insulated copper The wire connects the stainless steel plate to the cathode of the power supply, the sample is connected to the anode of the power supply, and the current density is controlled to 0.05A / cm 2 , the electrolysis time is 72h; after electrolysis, pour the electrolyte and anode mud into a 500ml large ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com