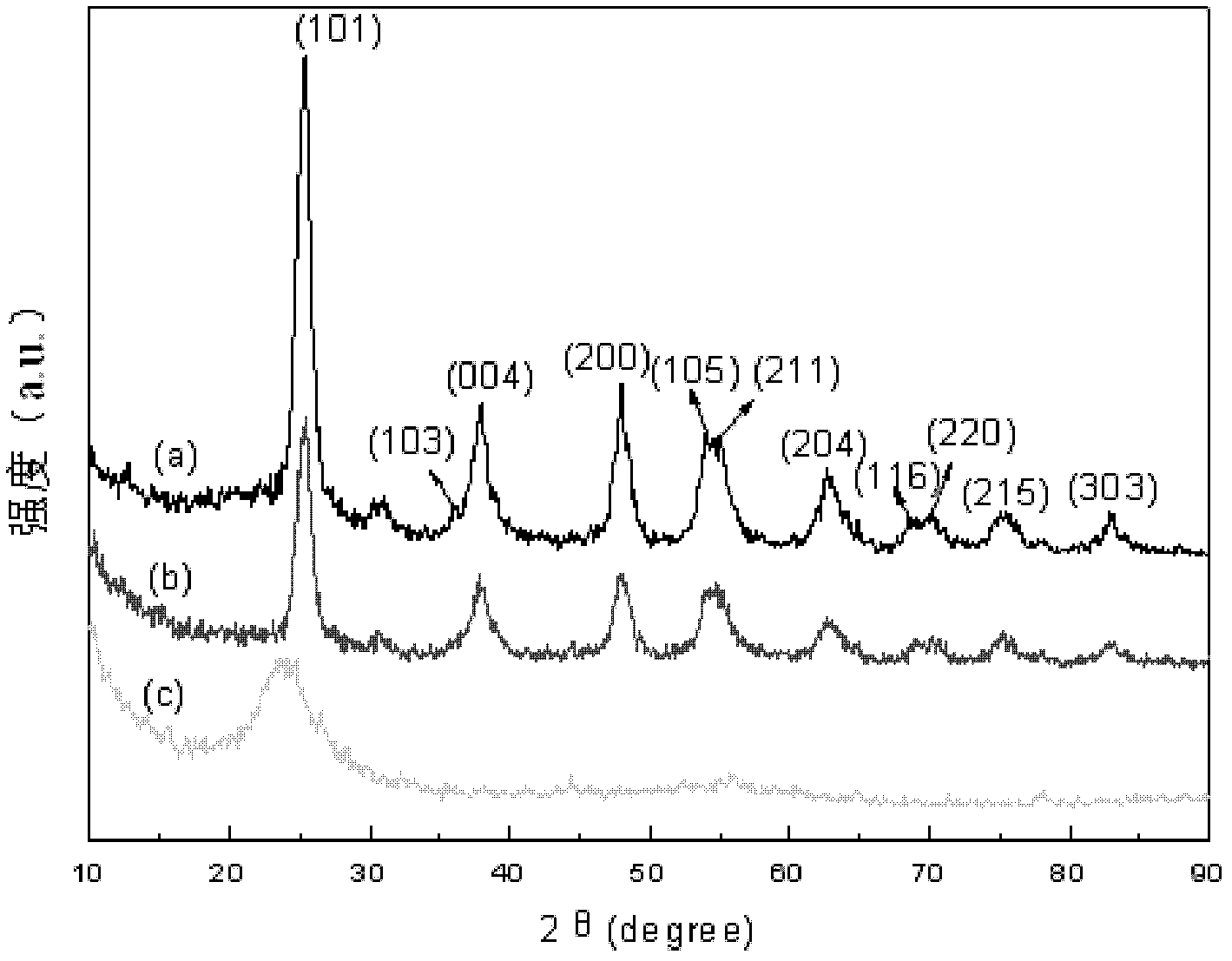

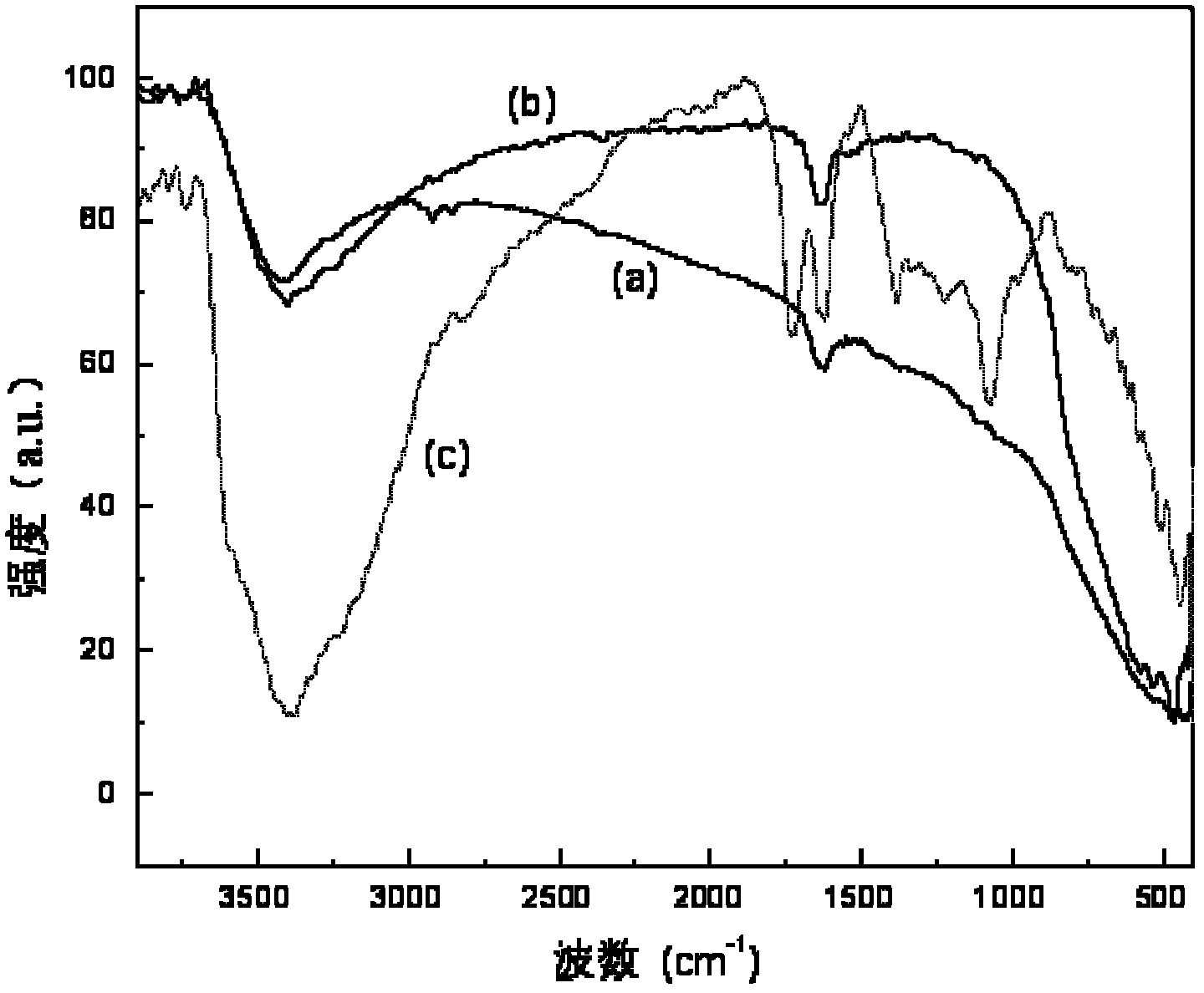

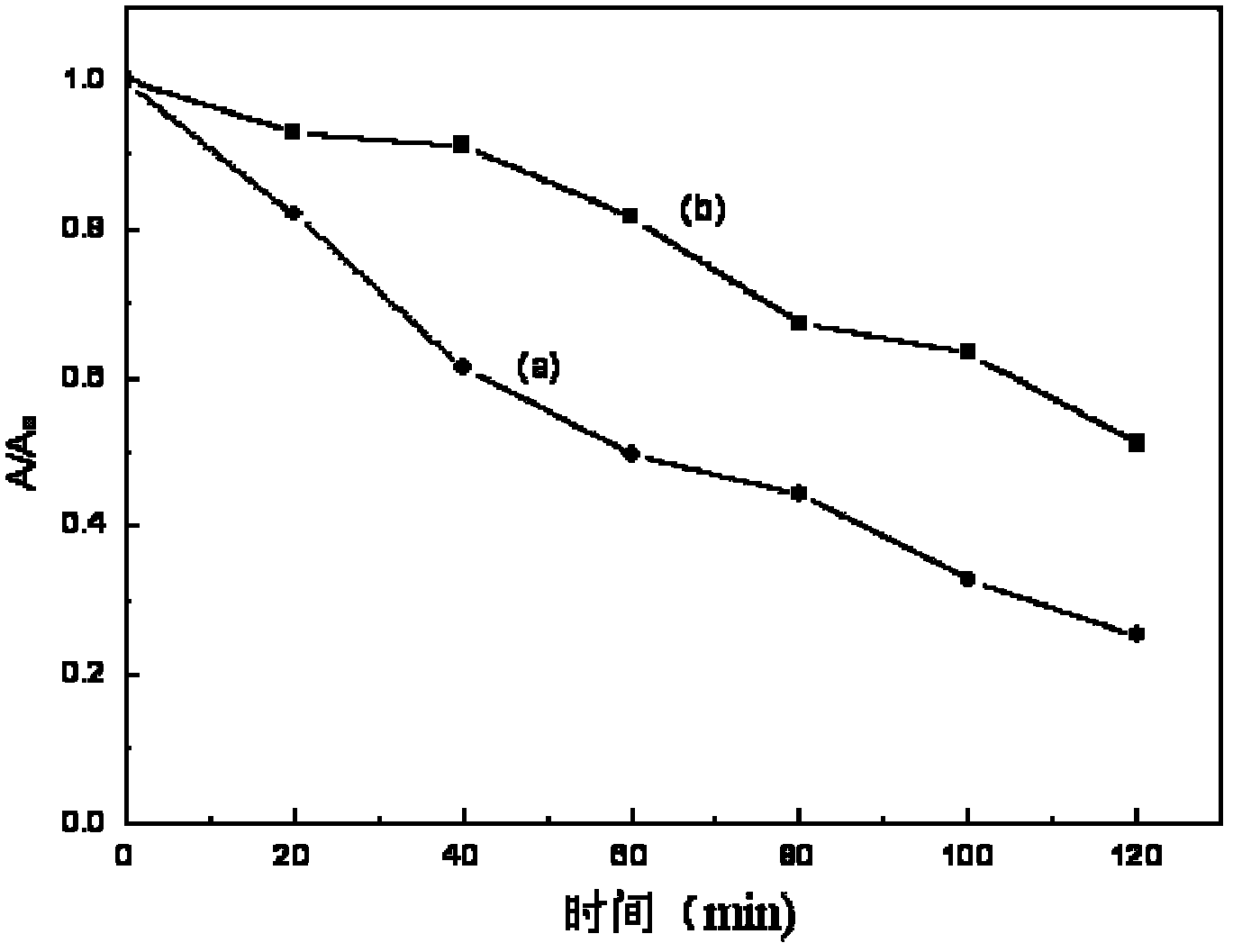

Preparation method of titanium dioxide/graphene composite photocatalyst

A graphene composite, photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes and other directions, can solve the problems of large particle size of titanium dioxide, low photocatalytic efficiency, etc., and achieves a simple and efficient preparation method. Environmental protection, avoid cumbersome, and enhance the effect of absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Specific embodiment one: the preparation method of a kind of titanium dioxide / graphene composite photocatalyst of the present embodiment is carried out according to the following steps:

[0022] 1. The mass ratio of tetrabutyl titanate to graphite oxide is 1: (0.001-0.03), the volume ratio of tetrabutyl titanate to concentrated acid is 15: (0.5-2), and the ratio of tetrabutyl titanate to graphite oxide is 1: (0.001-0.03). The volume ratio of ionized water is 15: (1~3) get tetrabutyl titanate, graphite oxide, concentrated acid and deionized water; Wherein the concentrated acid is the hydrochloric acid or the mass percent of 36%~38% by mass percent Nitric acid with a content of 65% to 68%;

[0023] 2. Dissolve the graphite oxide weighed in step 1 in an organic solvent, and perform ultrasonic dispersion treatment for 1 to 3 hours to obtain a graphene oxide dispersion;

[0024] 3. Add the tetrabutyl titanate measured in step 1 to the graphene oxide dispersion prepared in s...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment is different from Embodiment 1 in that the organic solvent described in step 2 is isopropanol or ethanol. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the mass ratio of tetrabutyl titanate and graphite oxide in step one is 1: (0.005~0.02), the ratio of tetrabutyl titanate and concentrated acid The volume ratio is 15:(1-1.5), and the volume ratio between tetrabutyl titanate and deionized water is 15:(1.5-2.5). Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com