Preparation method of nano ferrate/carbon nano tube composite materials

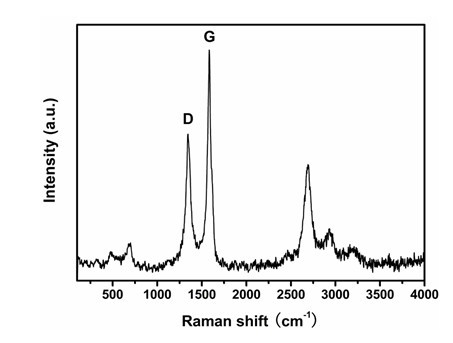

A technology of carbon nanotubes and composite materials, applied in iron compounds, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as nanoferrite/carbon nanotube composite materials that are rarely reported, and achieve excellent optoelectronics Activity, excellent performance, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Implementation example 1: the preparation method of nanometer cobalt ferrite / carbon nanotube (5 wt%) composite material, comprises the following steps:

[0033] In the first step, 0.5 g of carbon nanotubes were ultrasonically dispersed in 20 mL of concentrated nitric acid for 30 min;

[0034] In the second step, the carbon nanotubes in the first step were added to 80 mL of a mixed acid solution of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 1:1, heated to 90 °C, condensed and refluxed for 18 h;

[0035] In the third step, 10 mg of acidified carbon nanotubes was added to 20 mL of ethanol, and ultrasonically dispersed for 60 min;

[0036] In the fourth step, 2 mmol of ferric nitrate and 1 mmol of cobalt nitrate were added to 60 mL of ethanol and stirred for 10 min;

[0037] In the fifth step, the system obtained in the third step is mixed with the system obtained in the fourth step, and stirred for 30 min;

[0038] In the sixth step, t...

Embodiment 2

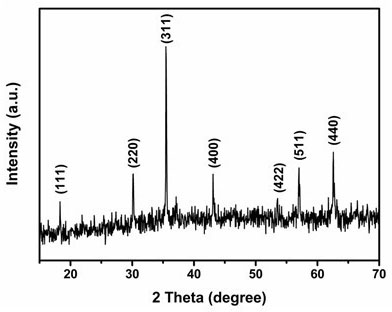

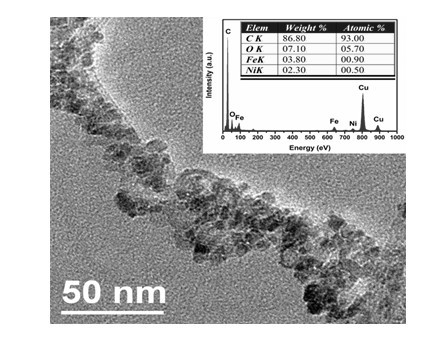

[0040] Implementation example 2: the preparation method of nanometer nickel ferrite / carbon nanotube (10 wt%) composite material, comprises the following steps:

[0041] In the first step, 1.0 g of carbon nanotubes were ultrasonically dispersed in 50 mL of concentrated nitric acid for 60 min;

[0042] In the second step, the carbon nanotubes in the first step are added to 100 mL of a mixed acid solution of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 1:1, heated to 100 ° C, condensed and refluxed for 12 h;

[0043] In the third step, 30 mg of acidified carbon nanotubes were added to 30 mL of ethanol, and ultrasonically dispersed for 90 minutes;

[0044] In the fourth step, 2 mmol of ferric nitrate and 1 mmol of nickel nitrate were added to 50 mL of ethanol and stirred for 30 min;

[0045] In the fifth step, the system obtained in the third step is mixed with the system obtained in the fourth step, and stirred for 60 min;

[0046] The sixth st...

Embodiment 3

[0051] Implementation example 3: the preparation method of nanometer copper ferrite / carbon nanotube (15 wt%) composite material, comprises the following steps:

[0052] In the first step, 1.5 g of carbon nanotubes were ultrasonically dispersed in 100 mL of concentrated nitric acid for 90 min;

[0053] In the second step, the carbon nanotubes in the first step were added to 150 mL of a mixed acid solution of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 1:1, heated to 120 °C, condensed and refluxed for 10 h;

[0054] In the third step, 45 mg of acidified carbon nanotubes were added to 40 mL of ethanol, and ultrasonically dispersed for 120 min;

[0055] In the fourth step, 2 mmol of ferric nitrate and 1 mmol of copper nitrate were added to 40 mL of ethanol and stirred for 50 min;

[0056] In the fifth step, the system obtained in the third step is mixed with the system obtained in the fourth step, and stirred for 90 min;

[0057] In the sixth s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com