Method for preparing metal silver nanostructure in water solution

A nanostructure and aqueous solution technology, which is applied in the field of preparing metallic silver nanostructures, can solve the problems of irregular nanostructure, complex operation, and single size, and achieve the effects of simple preparation process, low reaction temperature, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1.1 Mix 3 mL of silver nitrate aqueous solution with a concentration of 30 mM and 10 mL of sodium citrate aqueous solution, then add 3 mL of sodium chloride and polyvinylpyrrolidone aqueous solution, mix well, add 1.5 mg of sodium borohydride powder, and stir Finally, a uniform aqueous solution is obtained, wherein the weight ratio of silver nitrate / sodium chloride / sodium citrate / polyvinylpyrrolidone / sodium borohydride is 6:1:5:3:0.5.

[0028] 1.2 Take 10 mL of the aqueous solution described in Example 1.1, put it in an oil bath at 100 °C, and react at a constant temperature for 32 h.

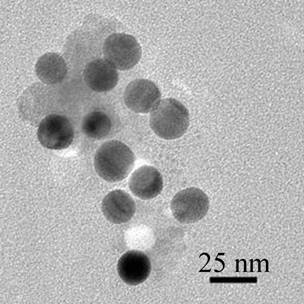

[0029] 1.3 After the reaction was finished, silver nanospheres with an average diameter of 23 nm were obtained after centrifugation and washing, such as figure 1 shown.

Embodiment 2

[0031] 2.1 Mix 2 mL of silver nitrate aqueous solution with a concentration of 450 mM and 10 mL of sodium citrate aqueous solution, then add 3 mL of sodium chloride and polyvinylpyrrolidone aqueous solution, mix well, add 1.5 mg of sodium borohydride powder, and stir Finally, a uniform aqueous solution is obtained, wherein the weight ratio of silver nitrate / sodium chloride / sodium citrate / polyvinylpyrrolidone / sodium borohydride is 6:1:5:7:0.5.

[0032]2.2 Take 10 mL of the aqueous solution described in Example 2.1, put it in an oil bath at 90 °C, and react at a constant temperature for 26 h.

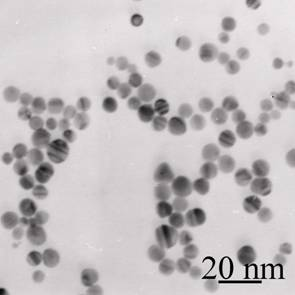

[0033] 2.3 After the reaction was finished, silver nanospheres with an average diameter of 8.5 nm were obtained after centrifugation and washing, such as figure 2 shown.

Embodiment 3

[0035] 3.1 Mix 0.6 mL of 100 mM silver nitrate aqueous solution with 12 mL of ascorbic acid aqueous solution, then add 2 mL of potassium chloride and N-methylpyrrolidone aqueous solution, mix and stir evenly, add 1.5 mg of sodium borohydride powder, and stir A uniform aqueous solution is obtained, wherein the weight of silver nitrate / potassium chloride / ascorbic acid / N-methylpyrrolidone / sodium borohydride is 6:1:5:7:0.5.

[0036] 3.2 Take 10 mL of the aqueous solution described in Example 3.1, put it in an oil bath at 80 °C, and react at a constant temperature for 40 h.

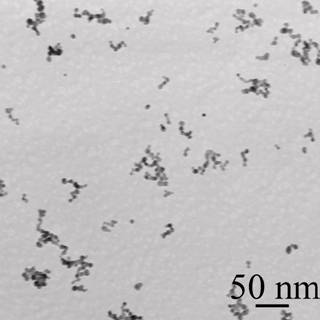

[0037] 3.3 After the reaction, silver nanospheres with an average diameter of 80 nm were obtained after centrifugation and washing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com