Production of phosphoric acid and multi-trace element potassium dihydrogen phosphate through using waste phosphorus mud

A technology of trace elements potassium dihydrogen phosphate and potassium dihydrogen phosphate, which is applied in the field of phosphorus chemical industry, can solve problems such as low purity of potassium dihydrogen phosphate, high equipment requirements, and high chloride ions, so as to reduce pollution, simplify process flow, Effect of reducing CO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

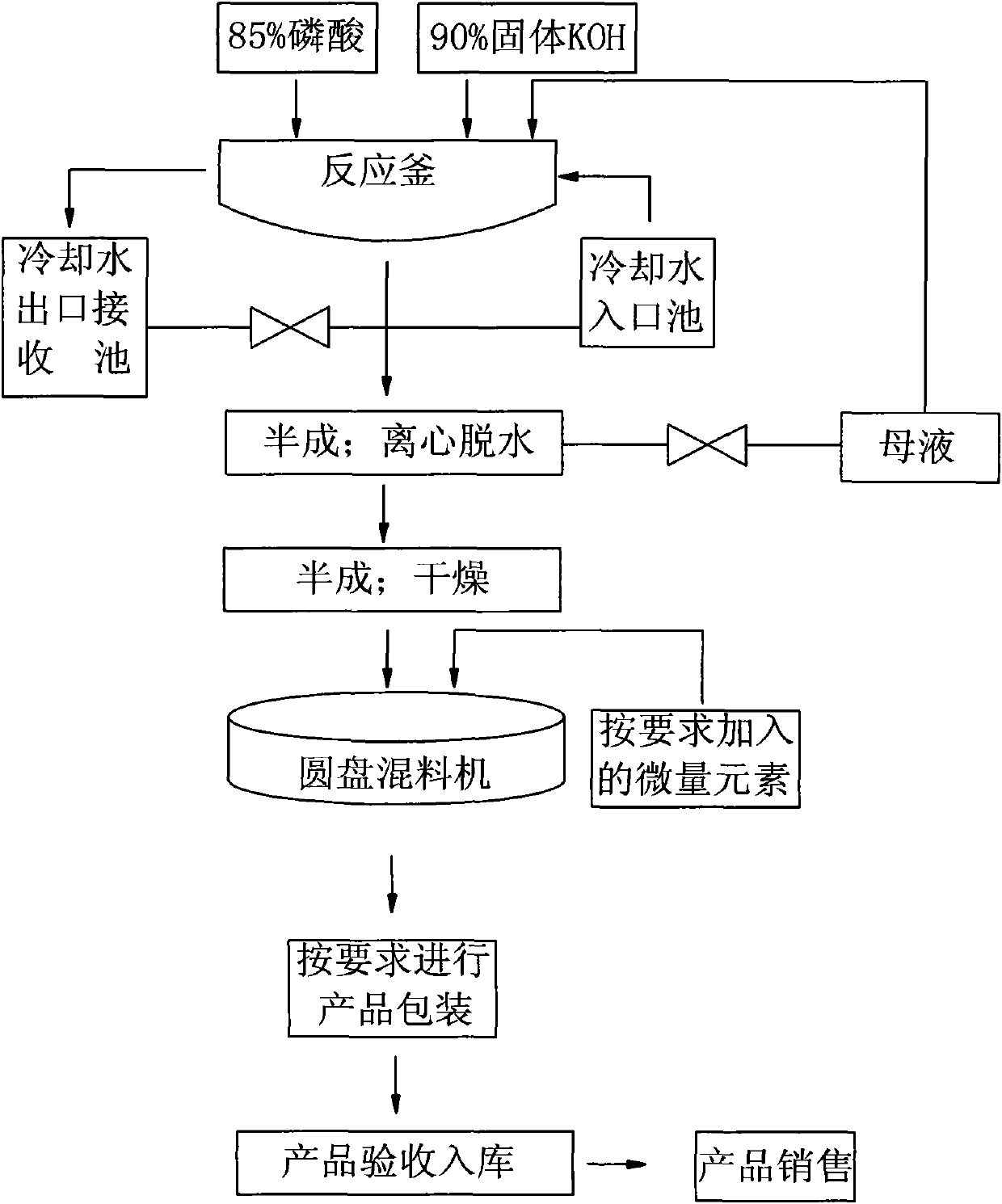

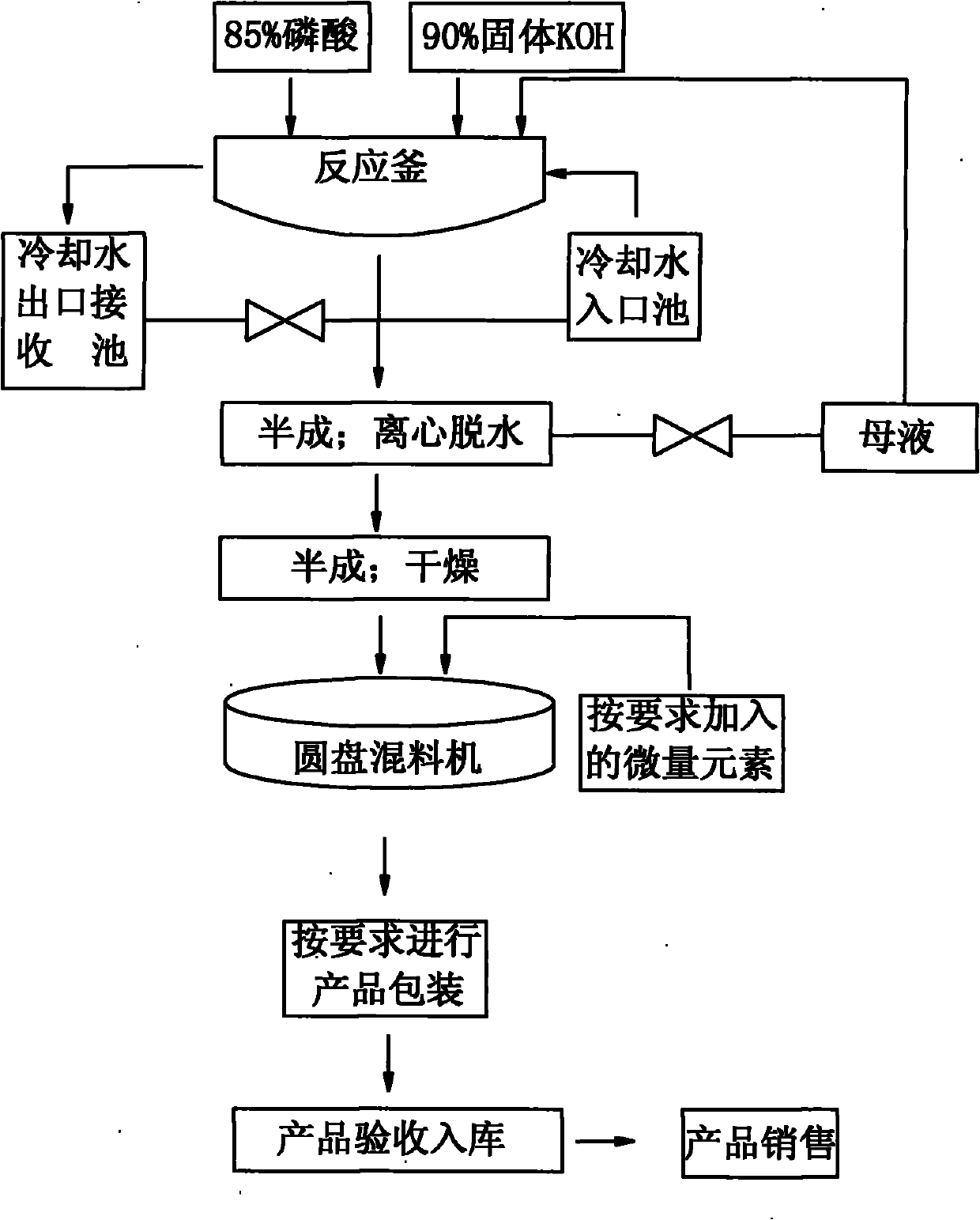

Method used

Image

Examples

Embodiment 1

[0020] Combine the potassium dihydrogen phosphate finished product obtained by the above method with 0.025% of iron, 0.013% of manganese, 0.01% of copper, 0.03% of zinc, and 0.2% of boron to match the required KH 2 OP 4 982.5kg, EDTA-Fe2kg, EDTA-Mn1kg, EDTA-Cu0.5kg, EDTA2kg, boric acid 12kg.

Embodiment 2

[0022] Combine the potassium dihydrogen phosphate finished product obtained by the above method with 0.05% of iron, 0.02% of manganese, 0.03% of copper, 0.02% of zinc, and 0.3% of boron to match the required KH 2 OP 4 973.4kg, EDTA-Fe4kg, EDTA-Mn1.6kg, EDTA-Cu2kg, EDTA-zn1.5kg, boric acid 17.5kg, mix and pack the above products evenly.

[0023] The above content of 13% EDTA-Fe; 13% EDTA-Mn; 15% EDTA-Cu; 15% EDTA-zn, boric acid containing 17.5% boron, all are commercial raw materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com