Film method aeration industrial flue gas desulfurization seawater recovery process

A technology for desulfurization of seawater and industrial flue gas, which is applied in gaseous effluent wastewater treatment, oxidized water/sewage treatment, permeation/dialysis water/sewage treatment, etc. problems, to achieve the effect of easy integration and amplification, small footprint, and high aeration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

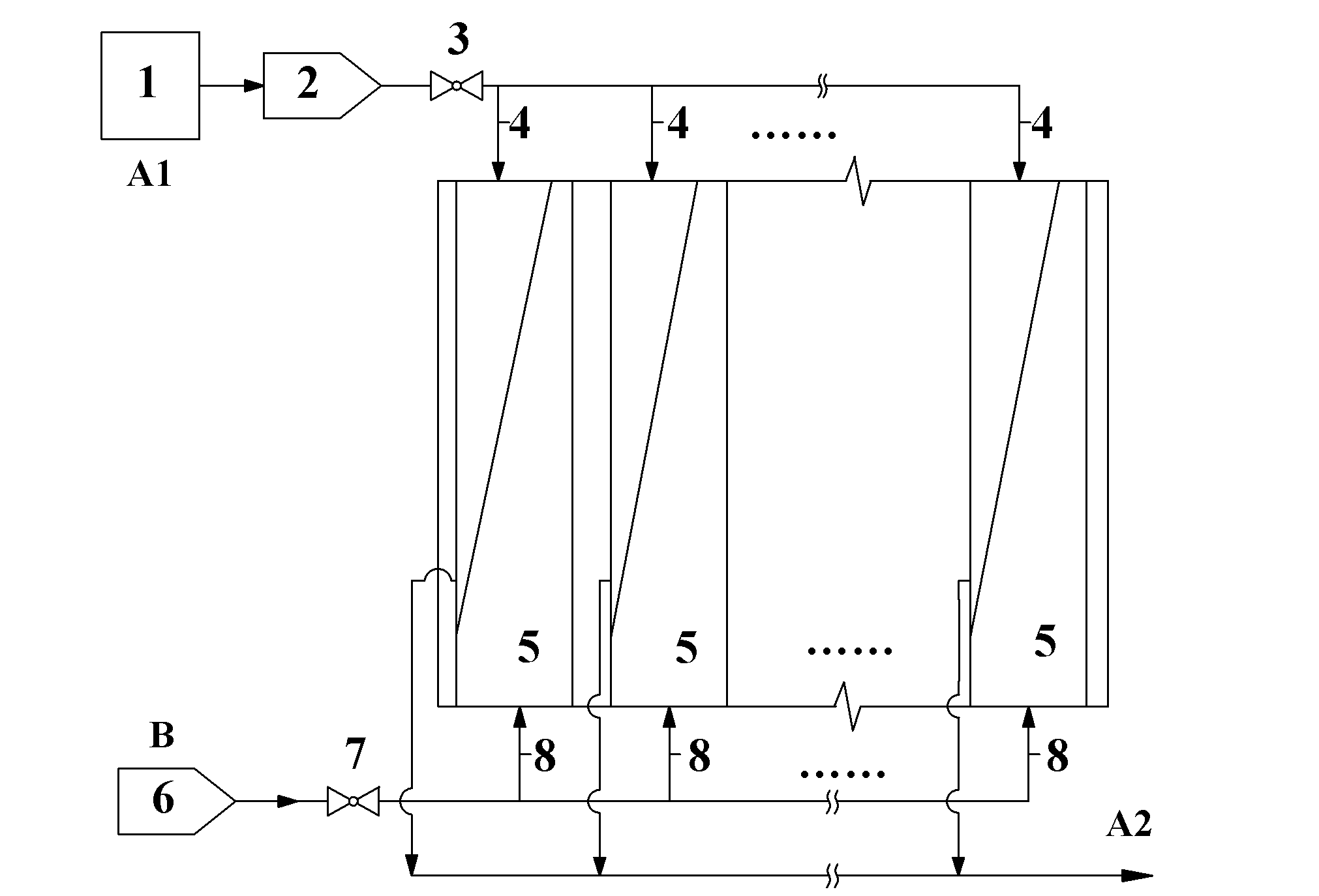

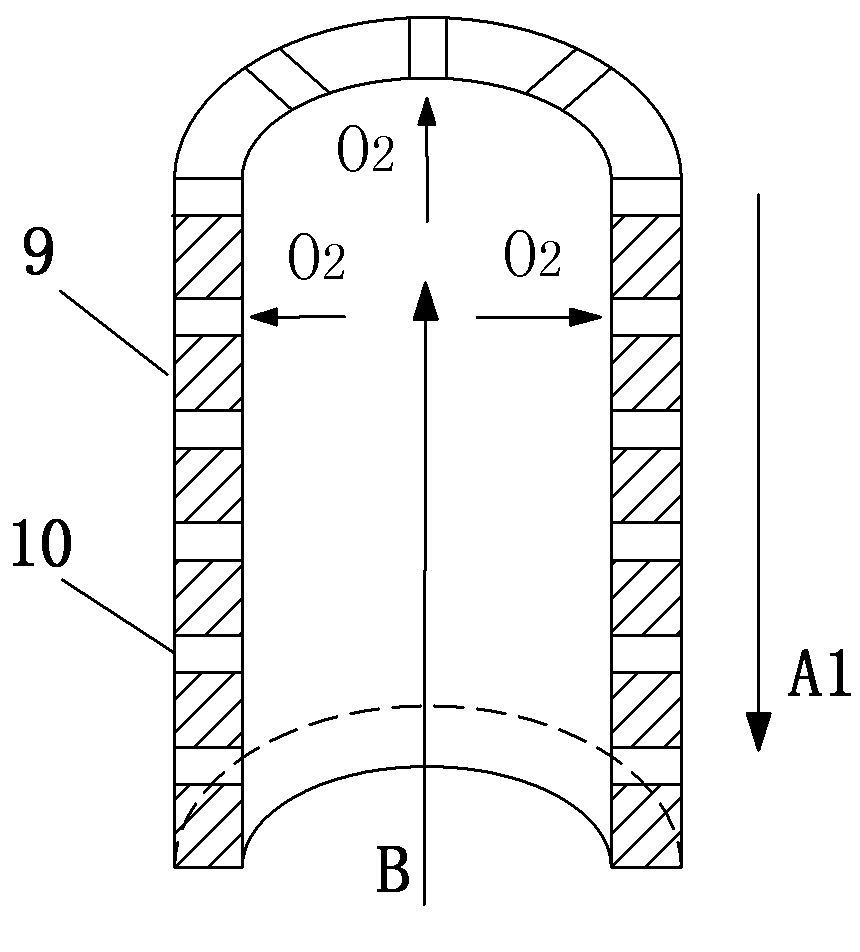

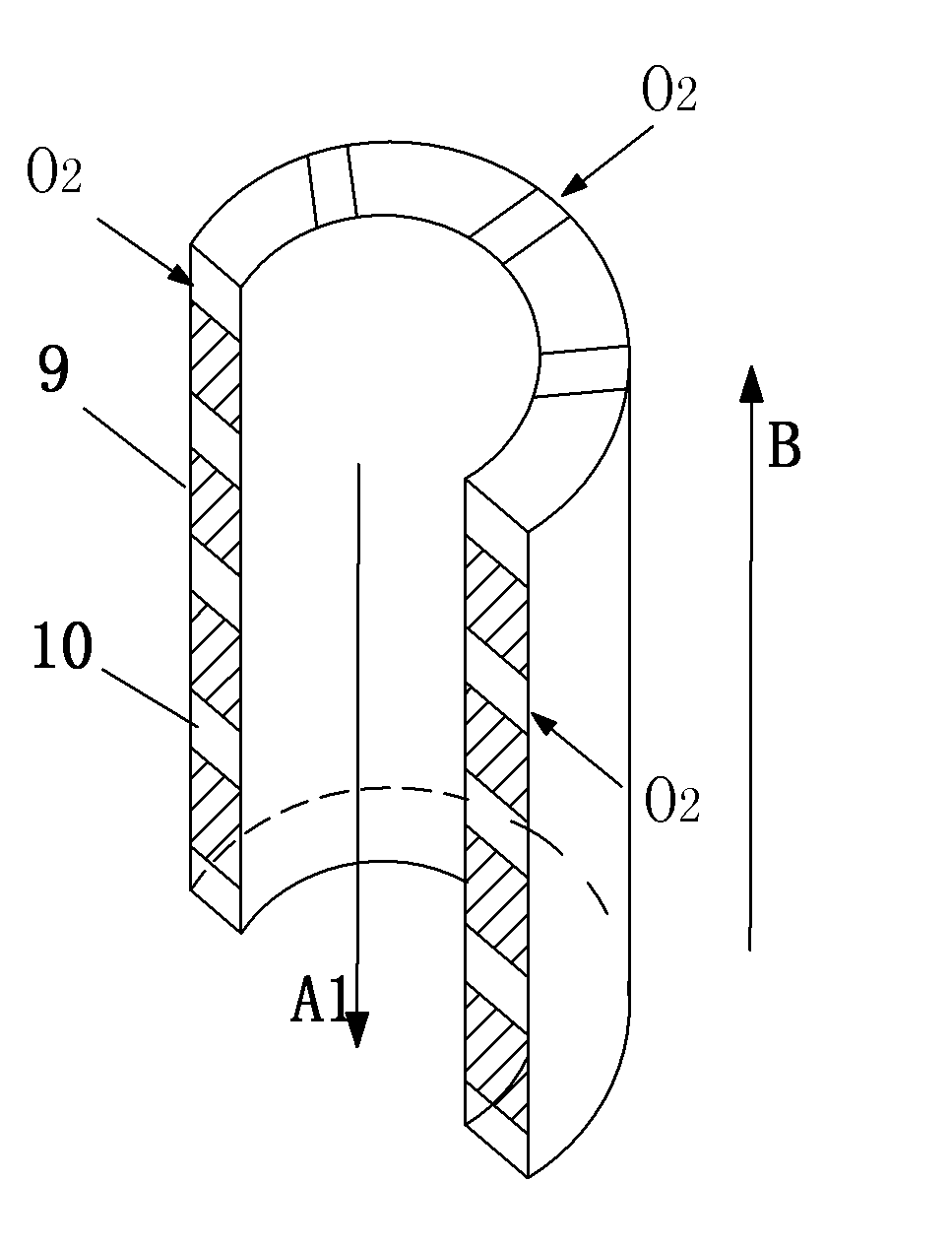

[0034] use as figure 1The shown membrane aeration industrial flue gas desulfurization seawater recovery process, the desulfurization core part of the device is composed of a first-stage hydrophobic hollow fiber column membrane module, which has a diameter of 90mm, an effective length of 900mm, and is filled with 5400 internal diameters of 400μm and an outer diameter of 500μm hydrophobic polypropylene hollow fiber membrane. The membrane filament is produced by melt spinning and stretching method, the maximum pore diameter ranges from 0.01 μm to 2.0 μm, and the wall thickness is 50 μm. The industrial flue gas desulfurization seawater is coal-fired flue gas desulfurization seawater, its pH value is 5.20, and its dissolved oxygen (DO) is 0mg / L. The oxygen-containing gas is compressed air, which is produced by an air compressor. The coal-fired flue gas desulfurization seawater A1 is mixed with fresh seawater through the water distribution area. The mixing ratio of fresh seawater ...

Embodiment 2

[0036] Using the same process, equipment and industrial flue gas desulfurization seawater as in Example 1 above, the oxygen-containing gas is pure oxygen, which is produced by an oxygen generator. Coal-fired flue gas desulfurization seawater A1 is mixed with fresh seawater through the water distribution area, the blending ratio is 3:1, and the seawater is adjusted to 0.6m through the corrosion-resistant pump 2 and the seawater flow control element 3 3 The flow rate of / h enters the 5 shell side of the hydrophobic hollow fiber membrane contactor. Pure oxygen B is produced by the oxygen steel cylinder 6, and the gas flow control element 7 is adjusted to make the pure oxygen flow at 0.08Nm 3 / h flow into the hydrophobic hollow fiber membrane contactor 5 tube side. The gas phase pressure is 70KPa, the liquid phase pressure is 30KPa, and the aeration time is 20s. Aeration restores the pH value of seawater A2 to 6.90, DO to 9.40mg / L, so as to meet the national seawater discharge st...

Embodiment 3

[0038] The same process, device, industrial flue gas desulfurization seawater and oxygen-containing gas are used as in the above-mentioned embodiment 1. Coal-fired flue gas desulfurization seawater A1 has a pH value of 2.70 and dissolved oxygen (DO) of 0mg / L. Coal-fired flue gas desulfurization seawater A1 is mixed with fresh seawater through the water distribution area. The blending ratio is 5:1. Pump 2, adjust the seawater flow control element 3 to make the seawater flow at 0.4m 3 The flow rate of / h enters the 5 shell side of the hydrophobic hollow fiber membrane contactor. The compressed air B is generated by the air compressor 6, and the gas flow control element 7 is adjusted to make the flue gas flow at 0.3Nm 3 / h flow into the hydrophobic hollow fiber membrane contactor 5 tube side. The gas phase pressure is 70KPa, the liquid phase pressure is 30KPa, and the aeration time is 20s. Aeration restores the pH value of seawater A2 to 6.91, DO to 4.03mg / L, so as to meet the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com