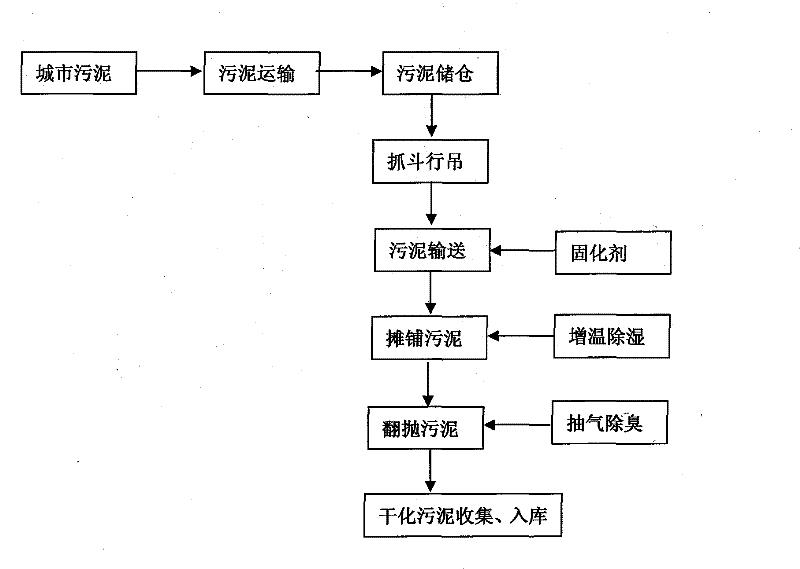

Sludge drying process

A sludge drying and sludge technology, which is applied in dehydration/drying/concentration sludge treatment, energy wastewater treatment, etc., can solve the problems of high water content in sludge, high energy consumption, and a large amount of toxic gas, etc., and achieve a high water content. Low, save energy, increase the effect of its own heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

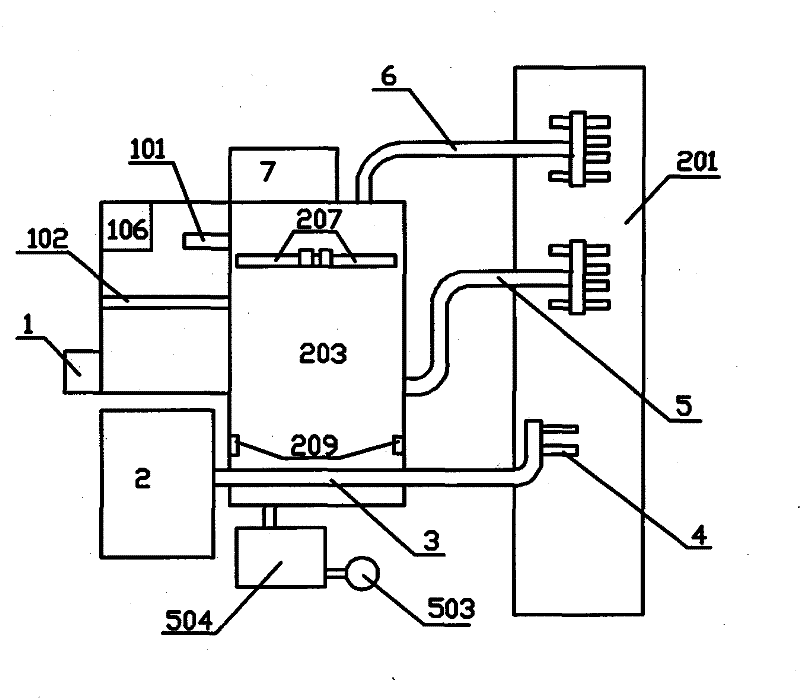

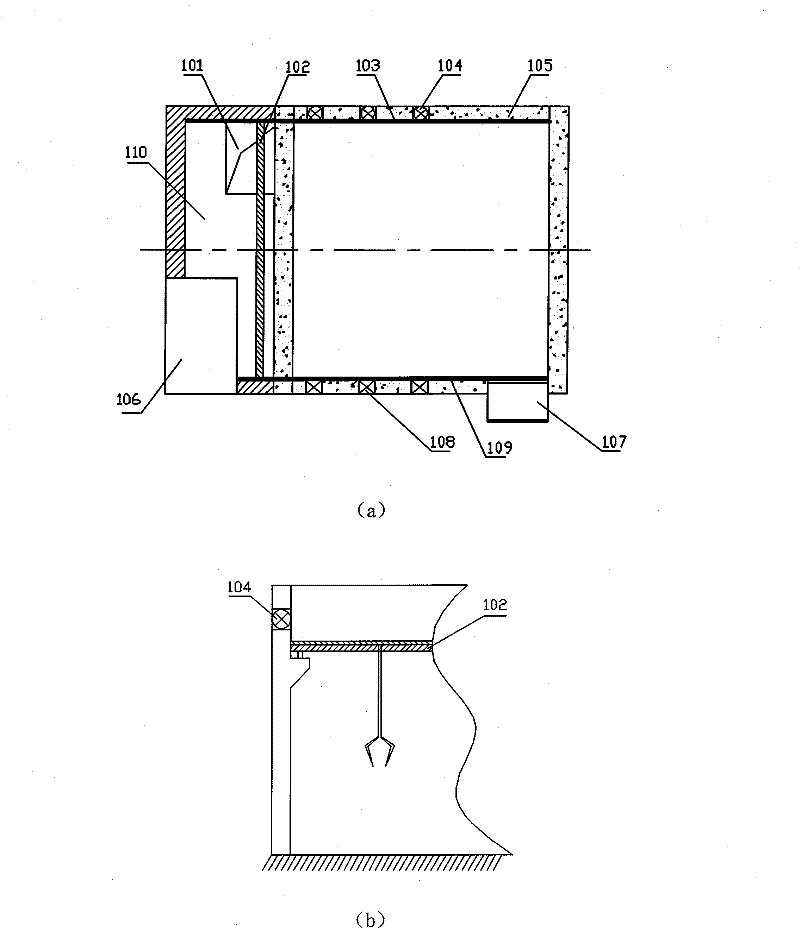

[0023] combine figure 1 , the sludge drying process of the present invention, first transport the municipal sludge with a moisture content of 80 to 85% to the sludge storage bin 106 for sealed storage, and control the grab bucket crane 102 to grab the sludge in the sludge storage bin 106 through the PLC system. The sludge is sent to the feeding hopper of the sludge feeding device 101 (the feeding device is a commonly used equipment in the industry), and at the same time, a curing agent is added in the feeding hopper (the curing agent is more conventional, and can be a normal temperature type curing agent and High-temperature curing agent, such as lime, water-based polyurethane, water-based acrylate, fluorine emulsion, silicone emulsion, etc.) and fully stirred, the sludge is transported to the drying chamber 203 of the drying equipment (sent to the sludge by extrusion In the collecting hopper of the paver), in the drying chamber 203, the waste heat of the solar energy and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com