Method for preparing double-gradient carbide modified C/C composite material

A composite material and carbide technology, which is applied in the field of preparation of double gradient carbide modified C/C composite materials, can solve the problem of poor thermal shock resistance of materials, no consideration of the micro gradient of carbon phase and ceramic phase, and low cost. The development trend of high-performance C/C composite materials and other issues, to achieve the effect of reducing weight and excellent ablation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

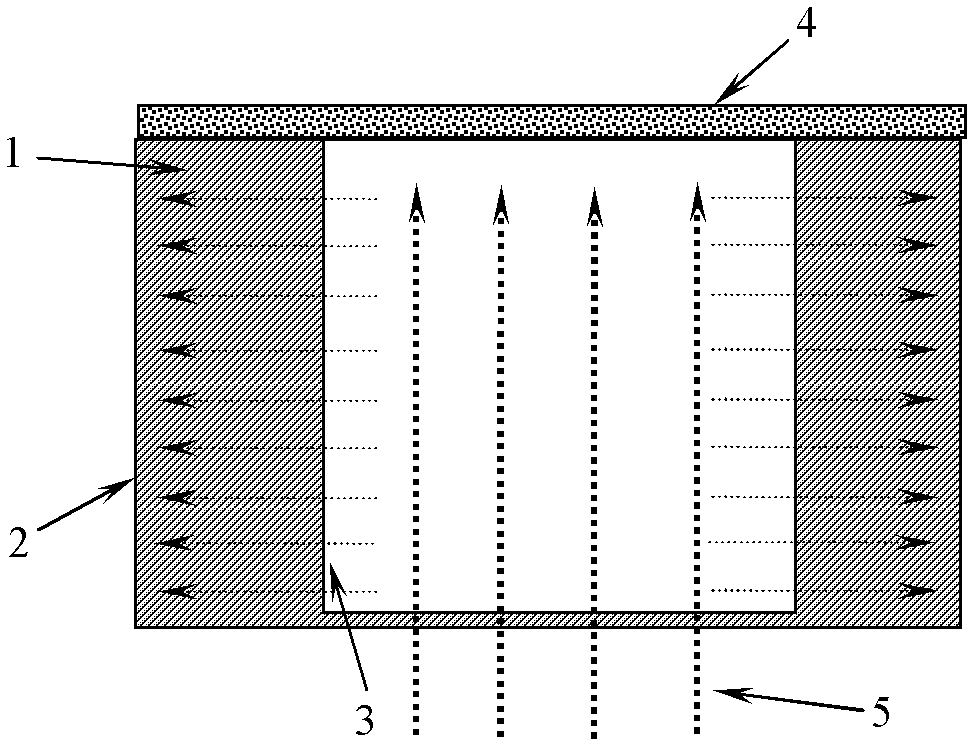

[0033] See attached figure 1 , take 2.5D woven C fiber preform (density 0.56±0.05g / cm 3 ), cut into a circular sample of Φ70 / Φ50)×25, weighed, and put it into a chemical vapor deposition furnace to ensure that the reaction gas diffuses into the C / C green body from the inner surface, and the reaction by-product gas is released from the outer surface. spread out, see figure 1 . Vacuum down to below 50Pa, and heat up to 800-950°C.

[0034] In the first stage, Ar-H2-CH4-TaCl5 reaction gas is passed into the CVD deposition furnace, the deposition time is 20h, and the gas ratio is 800:50:100:0, wherein carbon source gas / tantalum carbide source gas (5 tantalum chloride) with a volume ratio of 1:0; a 1-2 μm thick pure carbon layer is formed on the surface of the carbon fiber; in the second stage, the Ar-H2-CH4-TaCl5 reaction gas is introduced into the CVD deposition furnace, and the deposition time is 100h, the gas ratio is 800:50:100:10~90, wherein the volume ratio of carbon sour...

Embodiment 2

[0038] See attached figure 1 , take a three-dimensional woven fine-woven puncture felt (density 0.80±0.04g / cm 3 ), cut into a circular sample of Φ100 / Φ70×80, weighed, and put it into a chemical vapor deposition furnace to ensure that the reaction gas diffuses into the C / C green body from the inner surface, and the reaction by-product gas flows from the outer surface Spread out. Vacuum down to below 50Pa, heat up to 1400°C, and deposit ZrC-C co-deposition phase in the C / C green body. In the first stage, the Ar-H2-C3H6-ZrCl4 reaction gas is passed into the CVD deposition furnace, the deposition time is 8h, and the gas ratio is 800:50:40:0, wherein carbon source gas / zirconium carbide source gas (four Zirconium chloride) with a volume ratio of 1:0; a 1-2 μm thick pure carbon layer is formed on the surface of the carbon fiber; in the second stage, the Ar-H2-C3H6-ZrCl4 reaction gas is introduced into the CVD deposition furnace, and the deposition time 100h, the gas ratio is 800:5...

Embodiment 3

[0040] See attached figure 1 , take a three-dimensional woven fine-woven puncture felt (density 0.80±0.04g / cm 3 ), cut into a circular sample of Φ100 / Φ70×80, weighed, and put it into a chemical vapor deposition furnace to ensure that the reaction gas diffuses into the C / C green body from the inner surface, and the reaction by-product gas flows from the outer surface Spread out. Vacuum down to below 50Pa, heat up to 1600°C, and deposit HfC-C co-deposition phase in the C / C green body. In the first stage, Ar-H2-C3H6-HfCl4 reaction gas is passed into the CVD deposition furnace, the deposition time is 8h, and the gas ratio is 800:50:40:0, wherein carbon source gas / hafnium carbide source gas (four hafnium chloride) with a volume ratio of 1:0; a 1-2 μm thick pure carbon layer is formed on the carbon fiber surface; in the second stage, the Ar-H2-C3H6-HfCl4 reaction gas is introduced into the CVD deposition furnace, and the deposition time For 60h, the gas ratio is 800:50:40:20~100,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com