Deodorization, oxygen supply, heat collection and thermal insulation system for totally-enclosed sludge roller fertilizer making equipment

A thermal insulation system, fully enclosed technology, applied in the direction of sewage/sludge fertilizer, organic fertilizer preparation, organic fertilizer, etc., can solve the problems of large area, difficult site selection, atmospheric environmental pollution, etc., to reduce labor load, Simplify the process control process and promote the effect of material heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

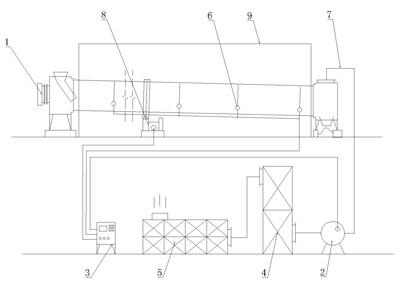

[0020] like figure 1 As shown in the present invention, a deodorization oxygen supply and heat collection and heat preservation system of a fully enclosed sludge drum fertilizer making equipment of the present invention includes an electric valve 1 at the air inlet, an oxygen supply fan 2, a central controller 3, a cyclone dust collector 4, and a biological Deodorizer 5, temperature sensing probe and oxygen concentration sensing probe 6, air duct 7, frequency conversion rotating motor 8 of fermentation device, solar fermentation shed 9.

[0021] The signal receiving end of the central controller 3 wirelessly receives the monitoring data signals of the temperature sensing probe and the oxygen concentration sensing probe 6, and the signal output end of the central controller 3 is connected to the frequency conversion rotating motor 8 of the sludge drum fermentation device, the electric valve 1 of the air inlet, Fan 2; the electric valve 1 of the air inlet is connected to the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com