Bismuth alginate and preparation method and application thereof

A technology of bismuth alginate and alginic acid is applied in the field of preparation of bismuth-containing compounds, which can solve the problems of inattention, non-negligible toxic and side effects, memory loss, etc., so as to reduce the activity of pepsin, improve the development value of new drugs, and promote the wound surface. healing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

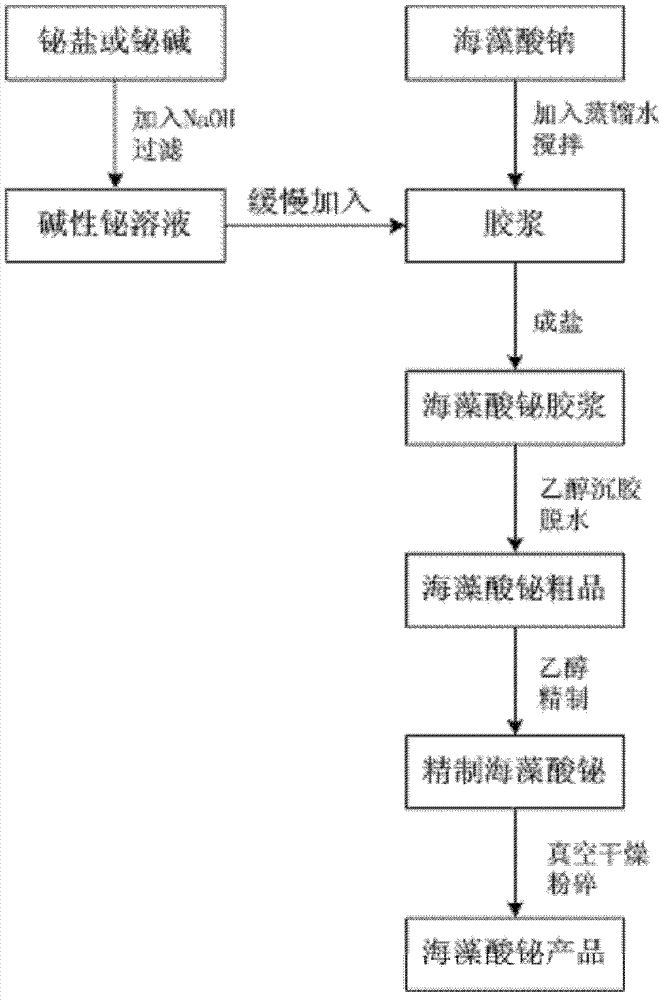

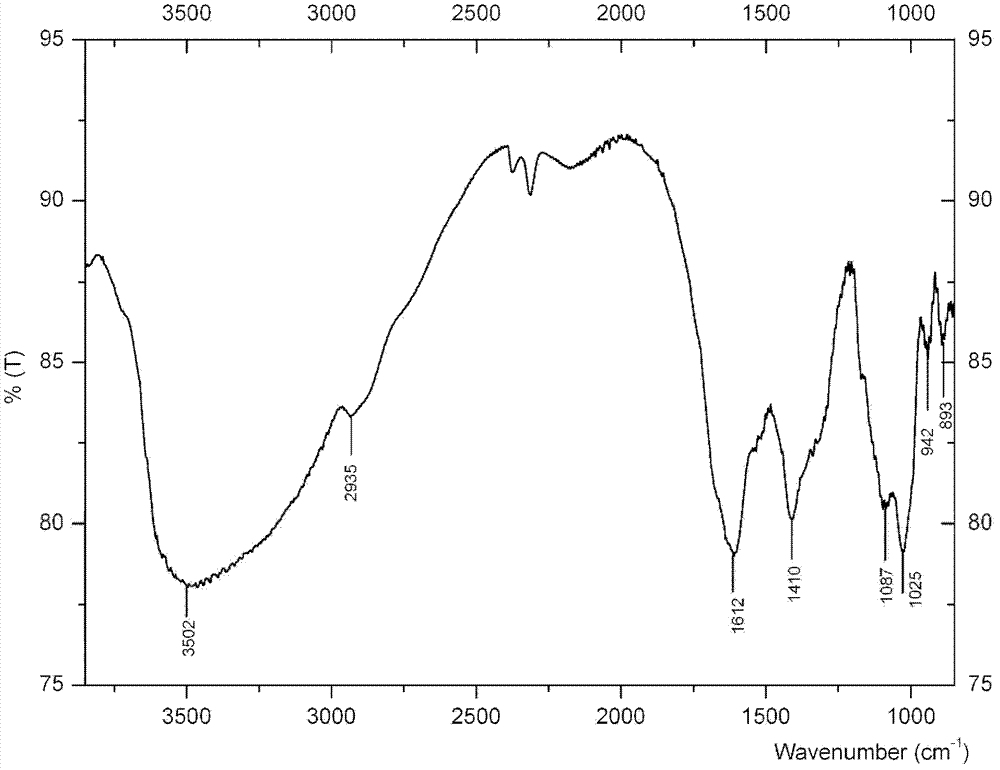

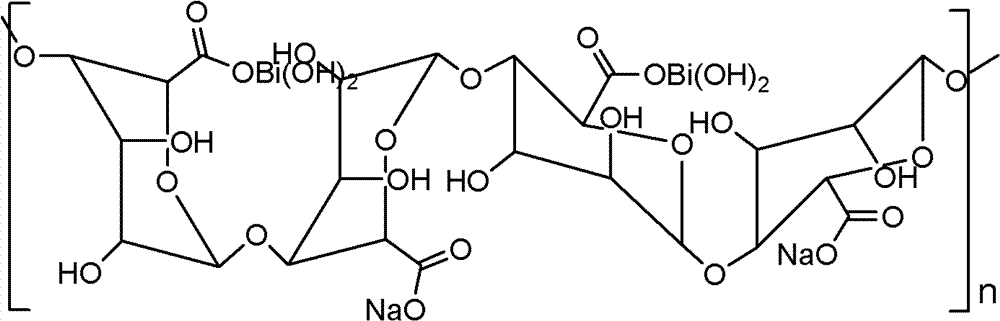

[0022] Preparation of bismuth alginate: first weigh 11 g of food-grade sodium alginate, add it to a container, and stir with 1500 ml of distilled water with a mixer until the sodium alginate is completely dissolved. Then adjust the pH to 8-12 with NaOH aqueous solution, continue to stir, and slowly add Bi(OH) 3 Aqueous solution (containing Bi 0.8g), continue to stir for 0.5-1 hour, and place the stirred solution at room temperature. Then add 95% ethanol that is 2-4 times (V / V) of the uniformly stirred solution, stir, colloid precipitates, press filter the precipitate, then wash the precipitate with ethanol for 2-3 times, vacuum freeze-dry, pulverize, and pass through 100 mesh Sieve to obtain bismuth alginate white powder (see figure 1 and figure 2 ), n=200-250 as shown in formula one. The obtained bismuth alginate contains 4-6% bismuth (by weight).

Embodiment 2

[0024] Weigh 10.5 g of sodium alginate, pour it into a container, add 1500 ml of water, and stir mechanically until it is completely dissolved to obtain a sodium alginate solution. Weigh bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O, containing Bi 2.0g), add water and stir until the bismuth nitrate is completely dissolved, then adjust the pH to 8-12 with NaOH solution; slowly add the bismuth nitrate alkaline solution into the sodium alginate solution while stirring, and continue stirring for 30-60min , and then add 1-3 times (V / V) ethanol to precipitate the bismuth alginate colloid, and centrifuge to separate the solid from the liquid. Add 95% ethanol to the precipitate to dehydrate and desalt the precipitate, then dry the precipitate, pulverize it, and pass through a 100-mesh sieve to obtain white powder bismuth alginate. The bismuth content in the bismuth alginate is 15-17%.

Embodiment 3

[0026] Weigh 10 g of sodium alginate, add it to a container, add 1500 ml of water, and stir mechanically until the sodium alginate is completely dissolved to obtain a sodium alginate solution. Weigh bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O, containing Bi 3.0g), add distilled water to dissolve, then add NaOH solution to get Bi(OH) 3 Precipitate, filter. Transfer the filter cake to a container, add 1-3 times (W / W) polyol, add water and stir until completely dissolved to obtain a basic bismuth solution; slowly add the bismuth alkali solution into the sodium alginate solution while stirring, and then continue Stir for 0.5-1 hour to form a colloidal salt. Then add 1-3 times (V / V) 95% ethanol, stir to precipitate bismuth alginate, and centrifuge. The precipitate was washed with 80% ethanol, dehydrated and desalted, and then the obtained precipitate was dried, pulverized, and passed through a 100-mesh sieve to obtain a white bismuth alginate powder. The powder contains 24-26% bismu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com