Method for preparing spherical magnesium chloride carrier

A technology of spherical carrier and magnesium chloride, applied in the field of preparation of magnesium chloride spherical carrier, can solve the problems of too many polymer fine powders, broken carrier balls, influence on catalyst morphology, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0050] Prepare magnesium chloride spherical carrier with the method of the present invention

[0051] (1) alcohol reaction

[0052] 20 grams (0.21mol) of magnesium chloride (water content 2.65% by mass), 39mL (0.67mol) of absolute ethanol, 110mL of methyl silicone oil, and 110mL of liquid paraffin were added to a 500mL reaction vessel equipped with a stirrer and a condenser tube under nitrogen protection. bottle, heated to 120°C and stirred for 3 hours. The viscosity of the methyl silicone oil at 20°C is 250 centipoise, and the viscosity of the liquid paraffin at 20°C is 30 centipoise.

[0053] (2) scattered

[0054] Move the solution obtained from the alcoholation reaction to a medium that has been preheated to 120°C and consists of 100mL methyl silicone oil and 100mL liquid paraffin. The volume ratio of the mixed medium to the adduct solution is 1.4, and it is stirred at a speed of 3000 rpm 30 minutes.

[0055] (3) Rapid cooling and solidification

[0056] The above emu...

example 2

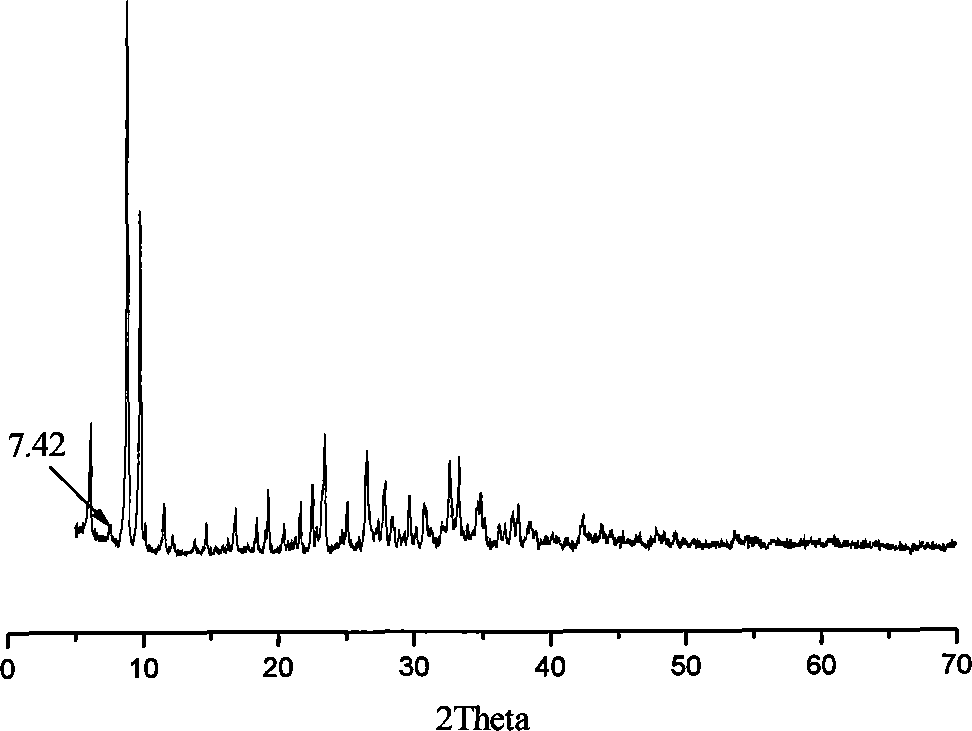

[0060] Get 5g carrier precursor ZT-0 and place in a fluidized bed reactor, fluidized dealcoholization under nitrogen, the mass space velocity of nitrogen passing through the carrier precursor is 10 hours -1 . Fluidized dealcoholization at 40°C for 1 hour, then raised to 50°C for 2 hours to obtain dealcoholization carrier ZT-2, the molar ratio of alcohol / magnesium was 2.60, and the specific surface area was 18 m 2 / g, pore volume 0.12 ml / g, bulk density 0.68g / mL, X-diffraction pattern see image 3 .

example 3

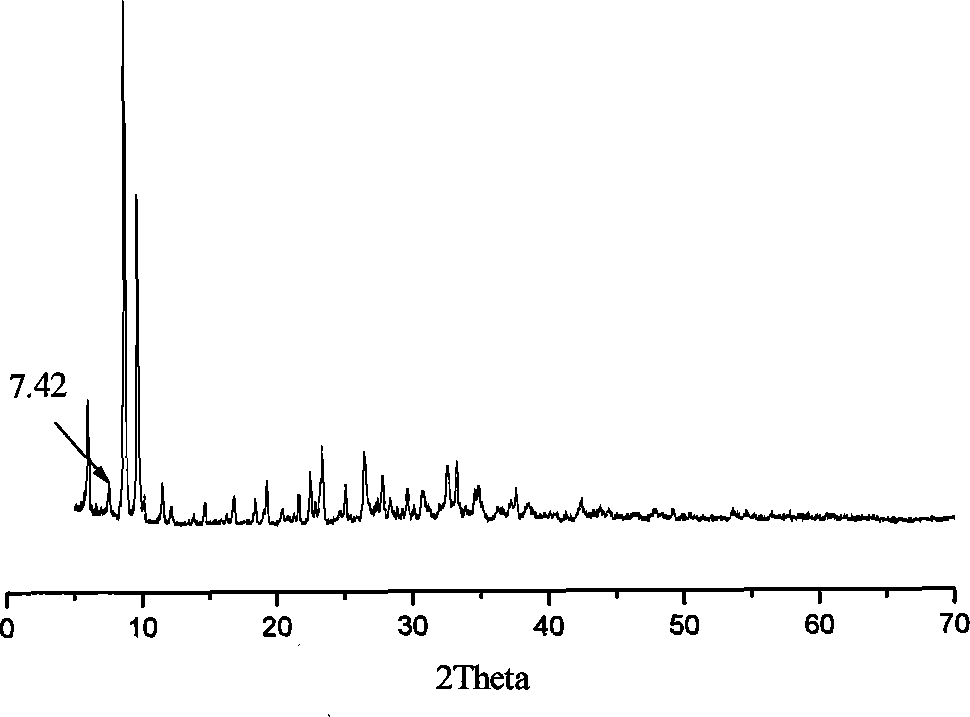

[0062] Get 5g carrier precursor ZT-0 and place in a fluidized bed reactor, fluidized dealcoholization under nitrogen, the mass space velocity of nitrogen passing through the carrier precursor is 10 hours -1 . Fluidized dealcoholization at 40°C for 1 hour, and then heated to 50°C for 3 hours to obtain dealcoholization carrier ZT-3, the molar ratio of alcohol / magnesium was 2.52, and the specific surface area was 20 m 2 / g, pore volume 0.16 ml / g, bulk density 0.63g / mL, X-diffraction pattern see Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com