Silicon sulfide rubber and preparation method thereof

A technology of vulcanized silicone rubber and catalyst, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problem of reducing the initial bonding strength, and achieve good bonding performance, excellent electrical performance and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

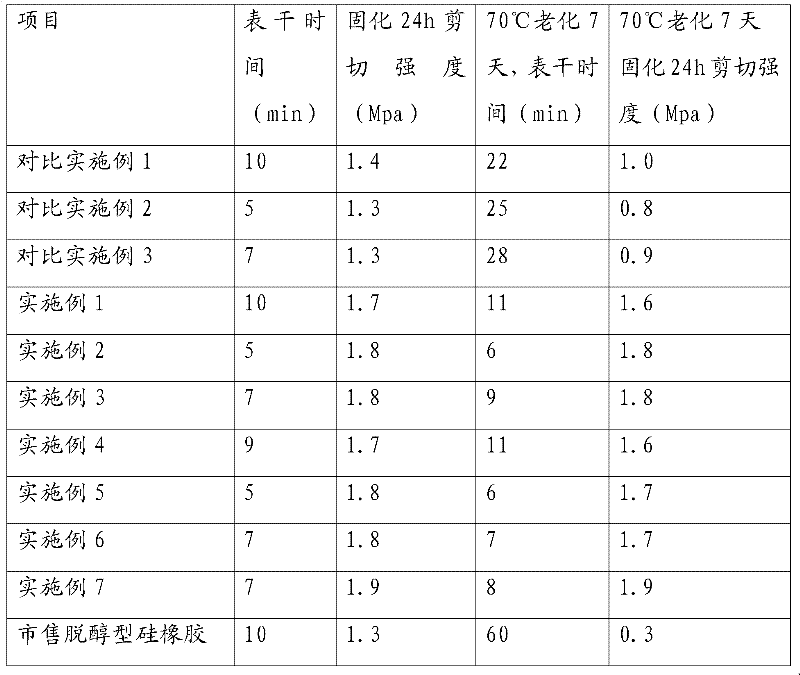

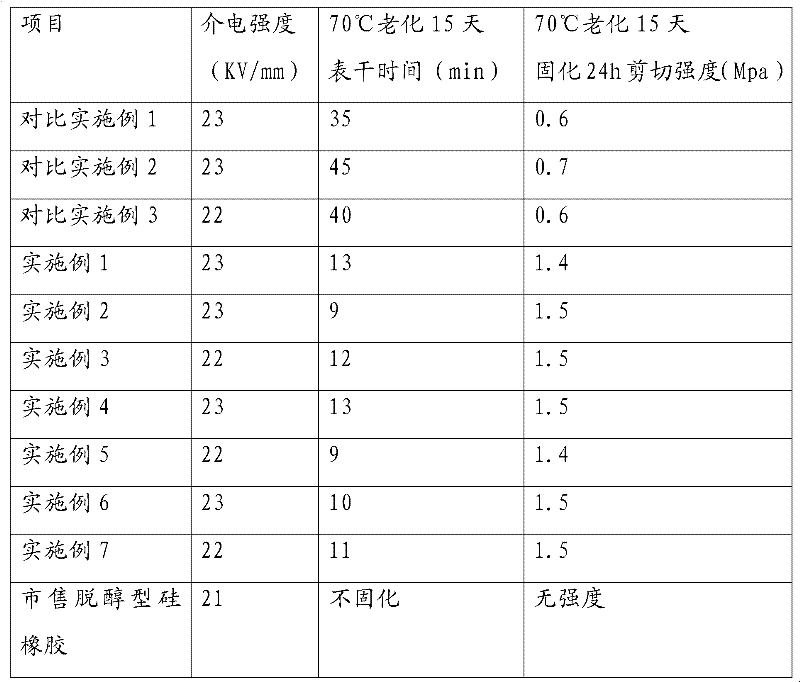

Examples

Embodiment 1

[0046] In a 5L planetary reactor, add 5000mPa.s vinyl-terminated polydimethylsiloxane 1000g, calcium carbonate 1000g, temperature 120°C, disperser rotation speed 500rpm, vacuum degree -0.098Mpa, continuous vacuum dehydration for 3h. Cool to 40°C, add 30g of trimethoxysilane and 5g of platinum catalyst and mix for 30min. Add 200g of 100mPa.s simethicone oil, 60g of white carbon black, 50g of methyltrimethoxysilane, 10g of stabilizer, 10g of γ-aminopropyltriethoxysilane, and 1g of dibutyltin dilaurate. Under the condition of vacuum degree -0.098Mpa, the speed of the dispersing disc is 400rpm, mix for 1 hour, let it air naturally at room temperature, and pack it.

Embodiment 2

[0048] In a 5L planetary reactor, add 20000mPa.s vinyl-terminated polydimethylsiloxane 1000g, calcium carbonate 2000g, temperature 150°C, disperser rotation speed 1000rpm, vacuum degree -0.1Mpa, and continuous vacuum dehydration for 4h. Cool to 50°C, add 50g of triethoxysilane and 10g of platinum catalyst and mix for 30min. Add 500g of 1000mPa.s simethicone oil, 100g of white carbon black, 100g of methyltrimethoxysilane, 20g of stabilizer, 20g of γ-aminopropyltriethoxysilane, and 5g of dibutyltin dilaurate. Under the condition of vacuum degree -0.1Mpa, the speed of the dispersing disc is 600rpm, mix for 2 hours, let it air naturally at room temperature, and pack it.

Embodiment 3

[0050] In a 5L planetary reactor, add 1000g of 10000mPa.s vinyl-terminated polydimethylsiloxane, 1500g of silicon micropowder, temperature 135°C, disperser rotation speed 750rpm, vacuum degree -0.099Mpa, continuous vacuum dehydration for 3.5h. Cool to 45°C, add 40g of trimethoxysilane and 7.5g of platinum catalyst and mix for 30min. Add 350g of 500mPa.s dimethyl silicone oil, 80g of white carbon black, 75g of methyltriethoxysilane, 15g of stabilizer, 15g of γ-aminopropyltriethoxysilane, and 3g of dibutyltin diacetate. Under the condition of vacuum degree -0.099Mpa, the speed of the dispersion disc is 500rpm, mix for 1.5 hours, let it air naturally at room temperature, and pack it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com