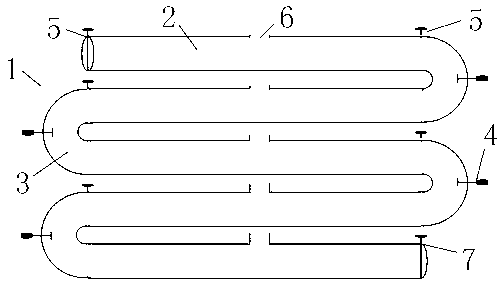

Controllable slope type microalgae cultivation system and microalgae cultivation method thereof

A culture system and microalgae technology, which is applied in the fields of medicine and health products, food, and energy, can solve the problems of inability to realize industrialized production, unfavorable industrialized production, and low production efficiency, and achieve easy implementation, reduced precipitation and wall attachment, and reduced energy the effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] For the initial cultivation, the controllable slope self-flow self-heating microalgae culture device is placed on the ocean tidal flat or artificial slope with a slope ratio of 1%-5%. Close the sampling valve, open the sampling valve, open the oxygen exhaust hole, introduce the algae liquid to be cultured into the reactor, fill it with appropriate amount of carbon dioxide, and cultivate it under sunlight for 12 hours (daytime). On the next day, open the sampling valve, introduce the algae liquid to be cultivated, control the flow rate at 10 cm / min, and flow the algae liquid in the entire culture vessel for 12 hours, which is equivalent to 20357.5 L of algae liquid, and the rate is 2.0 g / min. Calculating the wet algae concentration of L, a system can produce 40.7kg of wet algae per day, and the effective breeding time of a year is set at 200 days, so each system can produce 8.1 tons of wet algae per year. Each system covers an area of 80.0m 2 (Cultivator covers an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com