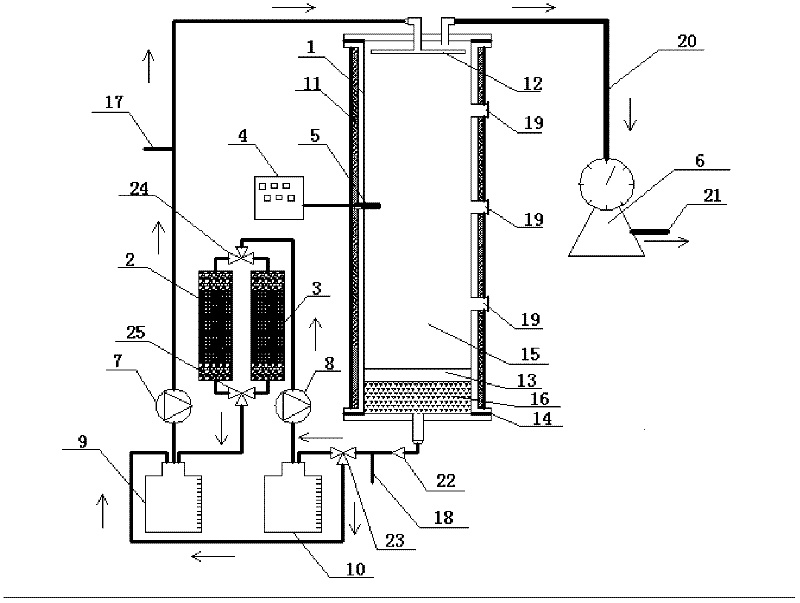

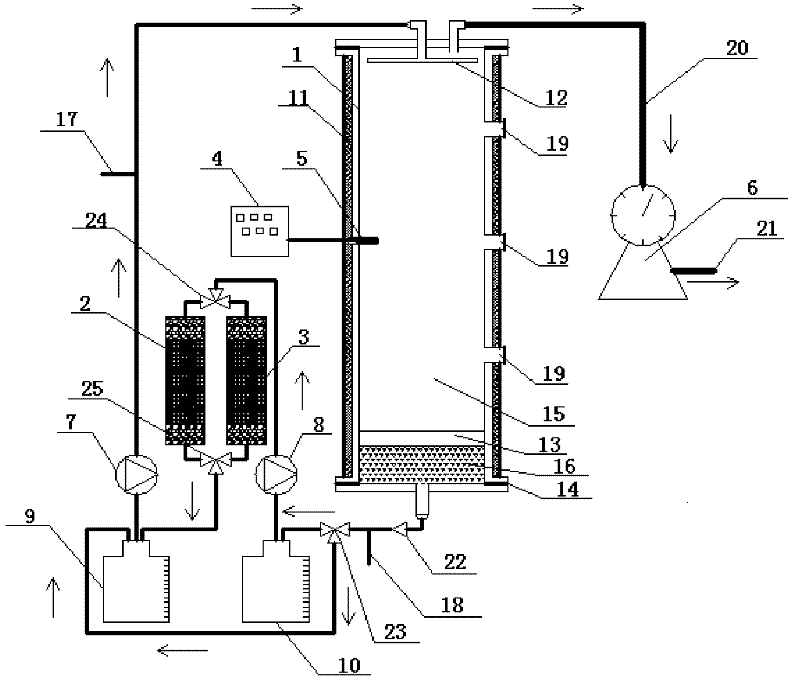

Dry anaerobic fermentation process and device for reducing ammonia nitrogen accumulation

A dry anaerobic fermentation and process technology, applied in the field of dry anaerobic fermentation, can solve the problems of decreased utilization rate of organic matter and nutrients, decreased activity of methanogens, slowed metabolism, etc., so as to relieve inhibition and realize recycling. , the effect of high gas production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The reflux frequency of the fermented liquid in the dry-type anaerobic fermentation reaction tank of the present invention is once a day, and the fermented liquid discharge valve at the bottom of the fermented tank is opened every morning, and the concentration of ammonia nitrogen is determined by sampling from the fermented liquid sampling port.

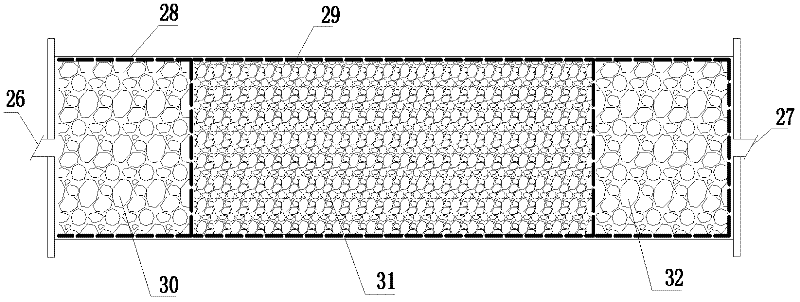

[0030] If the concentration of ammonia nitrogen reaches above 1500mg / L, open the first three-way valve at the bottom of the dry-type anaerobic fermentation reaction tank, so that the fermentation broth only flows into the second fermentation broth storage bottle; open the second three-way valve at the upper end of the zeolite packed column , so that the first zeolite packed column is in working condition; then use the peristaltic pump to send the fermentation broth to the first zeolite packed column to adsorb and remove the ammonia nitrogen in the fermentation broth; The quartz sand with larger particle size is filled, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com