Preparation method for erbium-ytterbium-doped polycrystalline oxide film

An oxide film, double doping technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of reducing Er emission-absorption efficiency, quenching, etc., to avoid concentration quenching phenomenon , the effect of high erbium-ytterbium doping concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

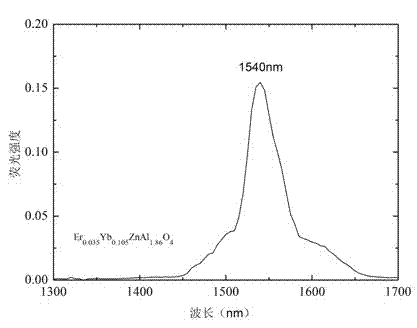

Embodiment 1

[0018] Er of the present invention x Yb y ZnAl (2-x-y) o 4 The preparation method of polycrystalline oxide thin film, comprises the following steps:

[0019] 1) Select the number of moles of Er element x =0.035, the number of moles of Yb element y =0.105, the calculated mass ratio of erbium, ytterbium, zinc and aluminum elements in the alloy target is 1:3.11:11.11:8.58. Add high-purity zinc (99.99%) and high-purity aluminum (99.99%) with a mass ratio of 11.11:8.58 into a high-temperature alloy melting furnace at 650°C to melt, stir evenly, and cool to cast zinc-aluminum binary alloy ingots; Then crush the zinc-aluminum binary alloy ingot in a vacuum environment, grind it into alloy powder with a ball mill, and set aside;

[0020] 2) High-purity rare earth erbium (99.9%) and high-purity rare earth ytterbium (99.9%) metal powder with the mass ratio of erbium and ytterbium elements determined in step 1) of 1:3.11 and the zinc-aluminum binary alloy prepared in step 1) The p...

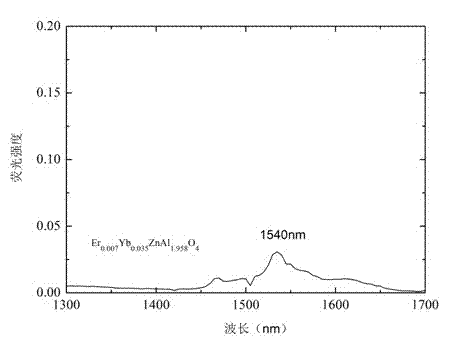

Embodiment 2

[0027] Er of the present invention x Yb y ZnAl (2-x-y) o 4 The preparation method of polycrystalline oxide thin film, comprises the following steps:

[0028] 1) Select the number of moles of Er element x =0.007, the number of moles of Yb element y =0.035, the calculated mass ratio of erbium, ytterbium, zinc and aluminum elements in the alloy target is 1:5.18:55.6:45.22. Add high-purity zinc (99.99%) and high-purity aluminum (99.99%) with a mass ratio of 55.6:45.22 into a high-temperature alloy melting furnace at 650°C to melt, stir evenly, and cool to cast zinc-aluminum binary alloy ingots; Then crush the zinc-aluminum binary alloy ingot in a vacuum environment, grind it into alloy powder with a ball mill, and set aside;

[0029] 2) High-purity rare earth erbium (99.9%) and high-purity rare earth ytterbium (99.9%) metal powder with the mass ratio of erbium and ytterbium elements determined in step 1) of 1:5.18 and the zinc-aluminum binary alloy prepared in step 1) The p...

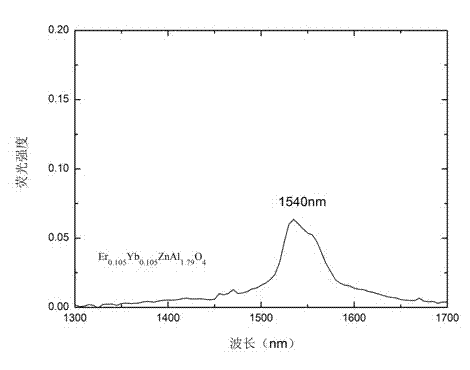

Embodiment 3

[0036] Er of the present invention x Yb y ZnAl (2-x-y) o 4 The preparation method of polycrystalline oxide thin film, comprises the following steps:

[0037] 1) Select the number of moles of Er element x =0.105, the number of moles of Yb element y =0.105, the calculated mass ratio of erbium, ytterbium, zinc and aluminum elements in the alloy target is 1:1.05:3.75:2.79. Add high-purity zinc (99.99%) and high-purity aluminum (99.99%) with a mass ratio of 3.75:2.79 to a high-temperature alloy melting furnace at 650°C to melt, stir evenly, and cool to cast zinc-aluminum binary alloy ingots; Then crush the zinc-aluminum binary alloy ingot in a vacuum environment, grind it into alloy powder with a ball mill, and set aside;

[0038] 2) High-purity rare earth erbium (99.9%) and high-purity rare earth ytterbium (99.9%) metal powder with the mass ratio of erbium and ytterbium elements determined in step 1) of 1:1.05 and the zinc-aluminum binary alloy prepared in step 1) The powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com