Method for doping silicon-based film by eutectic growth

A silicon-based film and surface normal technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of high requirements for experimental equipment, many film defects, uneven distribution of doping elements, etc., to achieve The doping amount is easy to control, the content is uniform, and the effect of high doping concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

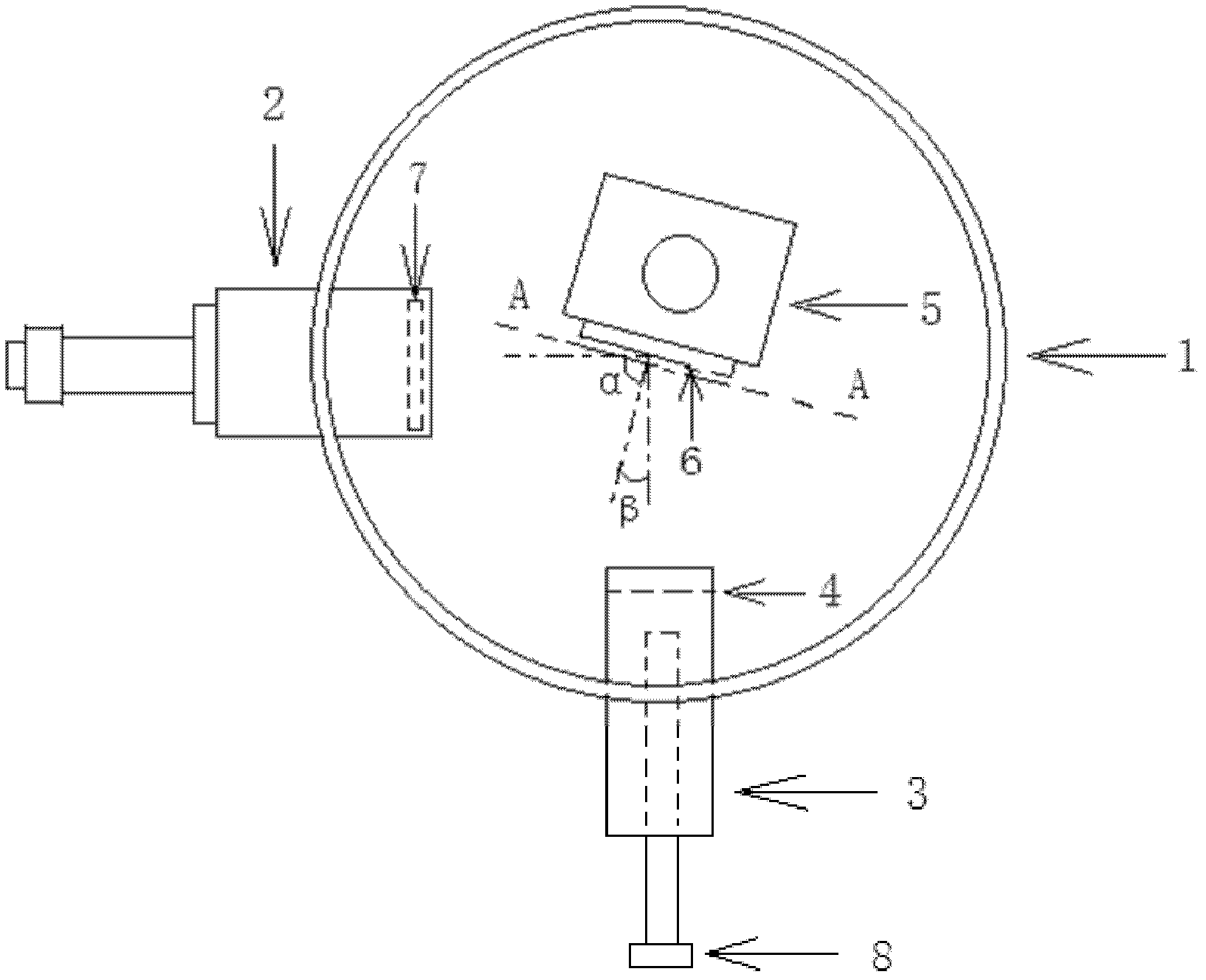

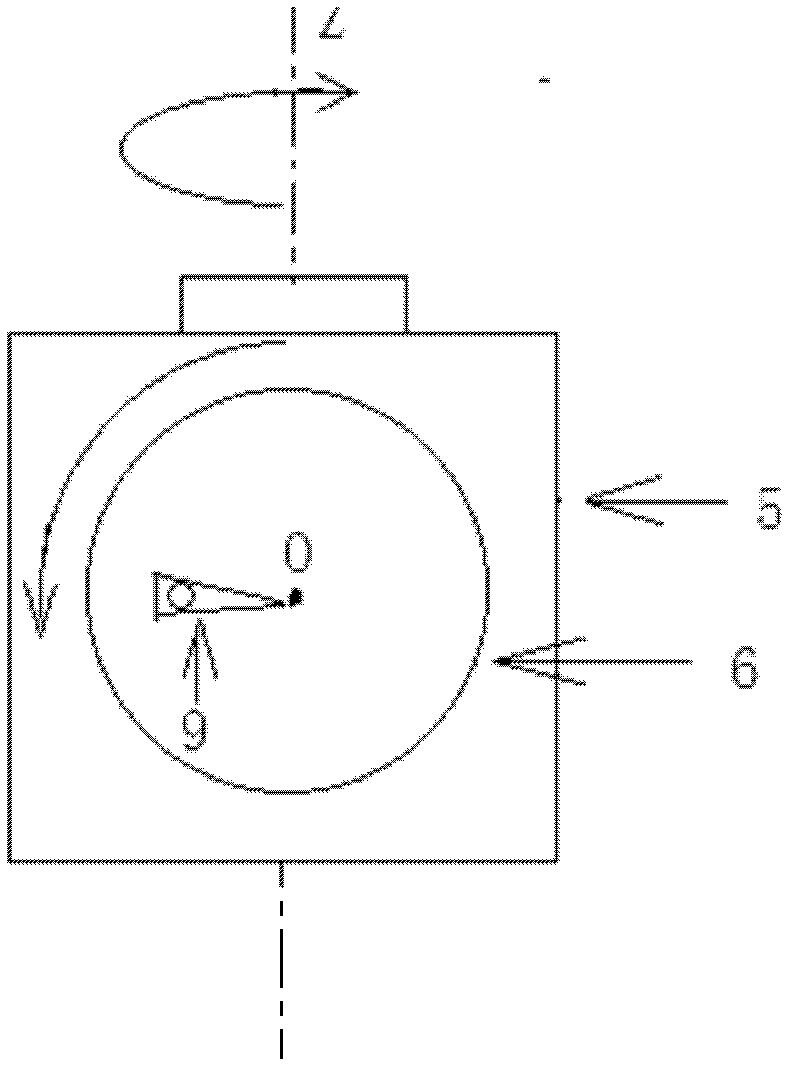

[0027] (1) The structure of the experimental device is as follows: figure 1 As shown, the distance between the hot wire source and the substrate is 8cm, the angle α=75 degrees between the normal line of the surface of the sample holder and the plane of the hot wire rack, and the sputtering target of the magnetron sputtering system has a purity of 99.995% titanium target;

[0028] (2) Put the cleaned substrate on the sample holder of the vacuum chamber so that the vacuum degree of the vacuum chamber is 3×10 -4 Pa;

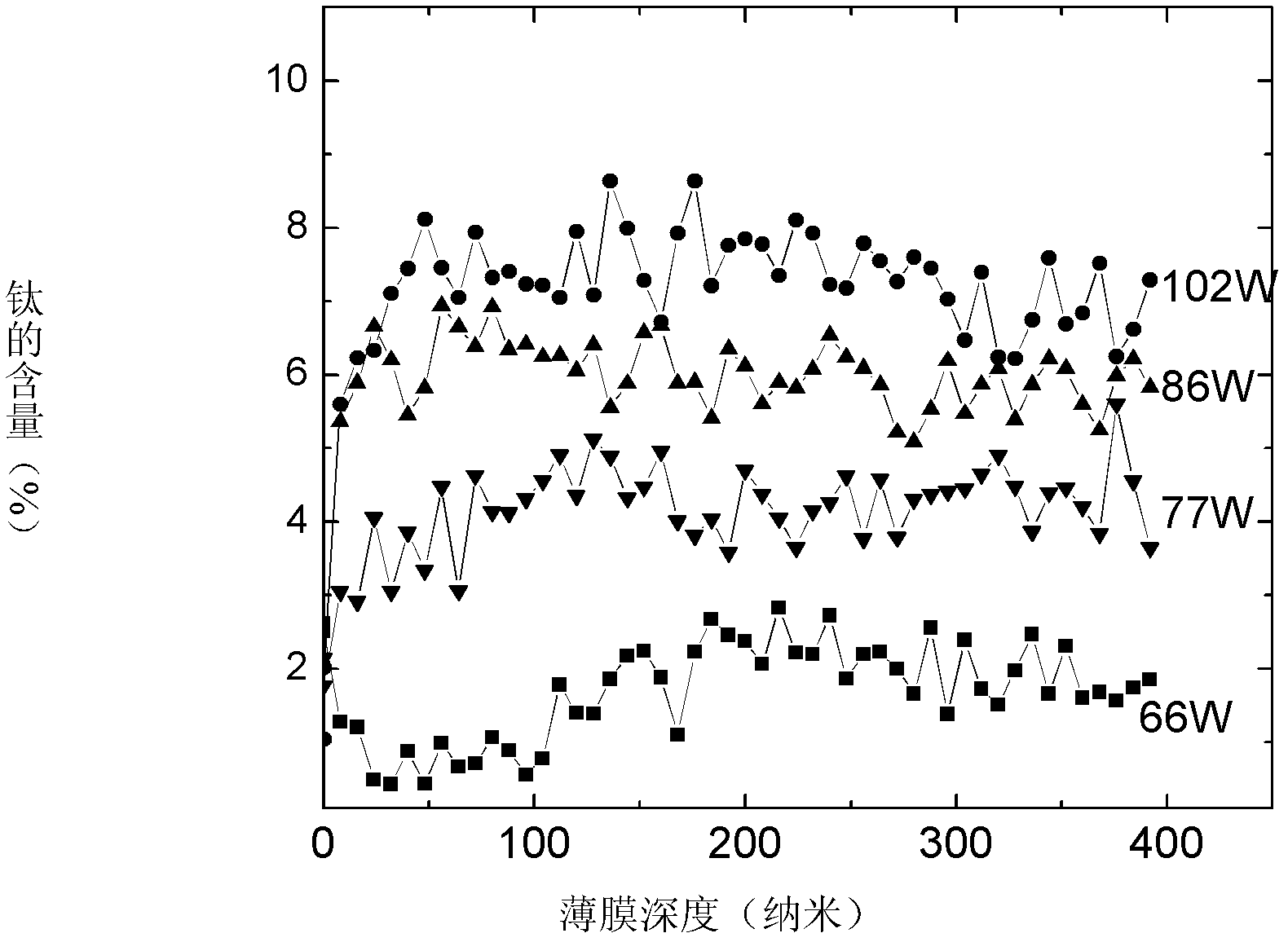

[0029] (3) feed reaction gas argon, hydrogen and silane in the vacuum chamber, the flow ratio of three kinds of gases is: hydrogen: argon: silane=12: 6: 6, make the air pressure of reaction gas in the cavity be 3 Pa, Heat the hot wire so that the temperature of the hot wire reaches 1800°C, apply a DC bias to the magnetron sputtering system, the power of the DC sputtering is 66 watts, and the rotation speed of the substrate holder relative to the sample stage is 5 ...

Embodiment 2

[0034] (1) The structure of the experimental device is as follows: figure 1 As shown, the distance between the hot wire source and the substrate is 8cm, the angle α between the normal of the surface of the sample holder and the plane of the hot wire holder is α=85 degrees, and the sputtering target of the magnetron sputtering system has a purity of 99.995 % titanium target;

[0035] (2) Put the cleaned substrate on the sample holder of the vacuum chamber so that the vacuum degree of the vacuum chamber is 5×10 -4 Pa;

[0036] (3) feed reaction gas argon, hydrogen and silane in the vacuum chamber, the flow ratio of three kinds of gases is: argon: hydrogen: silane=16: 6: 9, make the air pressure of reaction gas in the chamber be 4 Pa, Heat the hot wire so that the temperature of the hot wire reaches 1700°C, apply a DC bias to the magnetron sputtering system, the power of the DC sputtering is 105 watts, and the rotation speed of the substrate holder relative to the sample stage ...

Embodiment 3

[0040] (1) The structure of the experimental device is as follows: figure 1As shown, the distance between the hot wire source and the substrate is 8cm, the angle α between the normal of the sample holder surface and the plane of the hot wire holder is α=75 degrees, and the sputtering target of the magnetron sputtering system has a purity of 99.99% % silver target;

[0041] (2) Put the cleaned substrate on the sample holder of the vacuum chamber so that the vacuum degree of the vacuum chamber is 5×10 -4 Pa;

[0042] (3) feed reaction gas argon, hydrogen and silane in the vacuum chamber, the flow ratio of three kinds of gases is: argon: hydrogen: silane=8: 6: 6, make the air pressure of reaction gas in the chamber be 2 Pa, Heat the hot wire so that the temperature of the hot wire reaches 1700°C, apply a DC bias to the magnetron sputtering system, the power of the DC sputtering is 76 watts, and the rotation speed of the substrate holder relative to the sample stage is 5 rpm;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com