Method for measuring content of aluminum, silicon and zinc in coating of aluminum-plated zinc plate

A technology of galvanizing and zinc content, which is applied in the field of inspection and testing, can solve the problems of many analytical procedures of chemical methods, various types of chemical agents, and strict requirements on the operation process, and achieve the effects of less dosage, high accuracy, and simplified procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Preparation before analysis:

[0034] Prepare reagents:

[0035] Prepare high-purity iron, absolute ethanol and hydrochloric acid with a bulk density of 1.19 g / ml.

[0036] Weigh 10 g of sodium hydroxide solid, add 100 ml of water, and mix to obtain a 10% by mass sodium hydroxide aqueous solution.

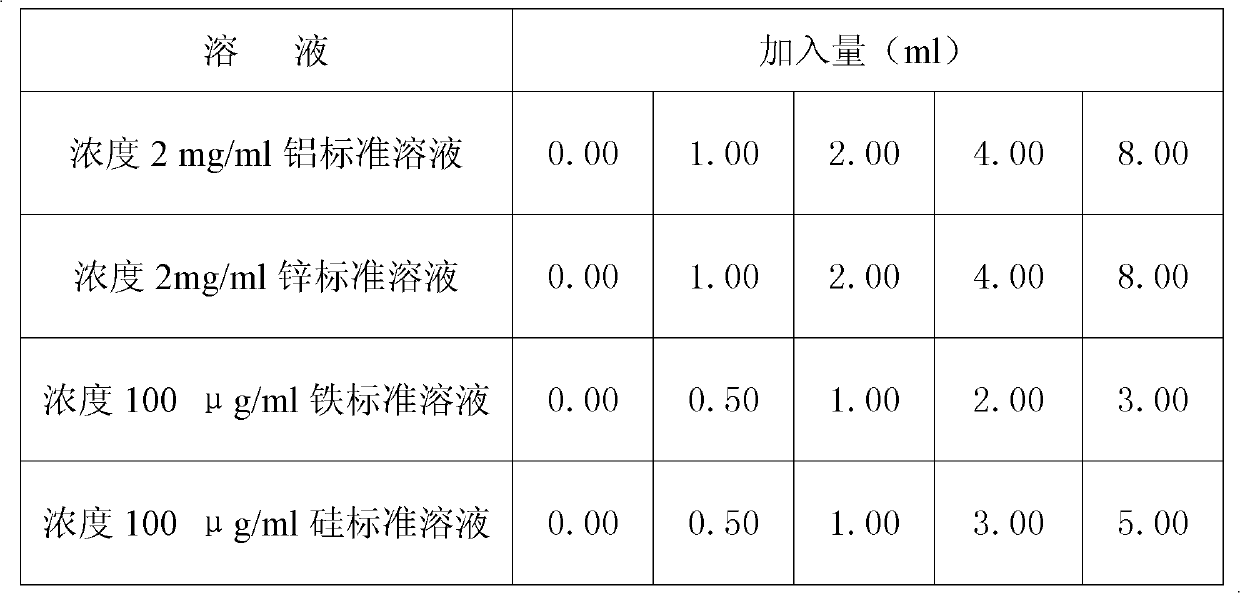

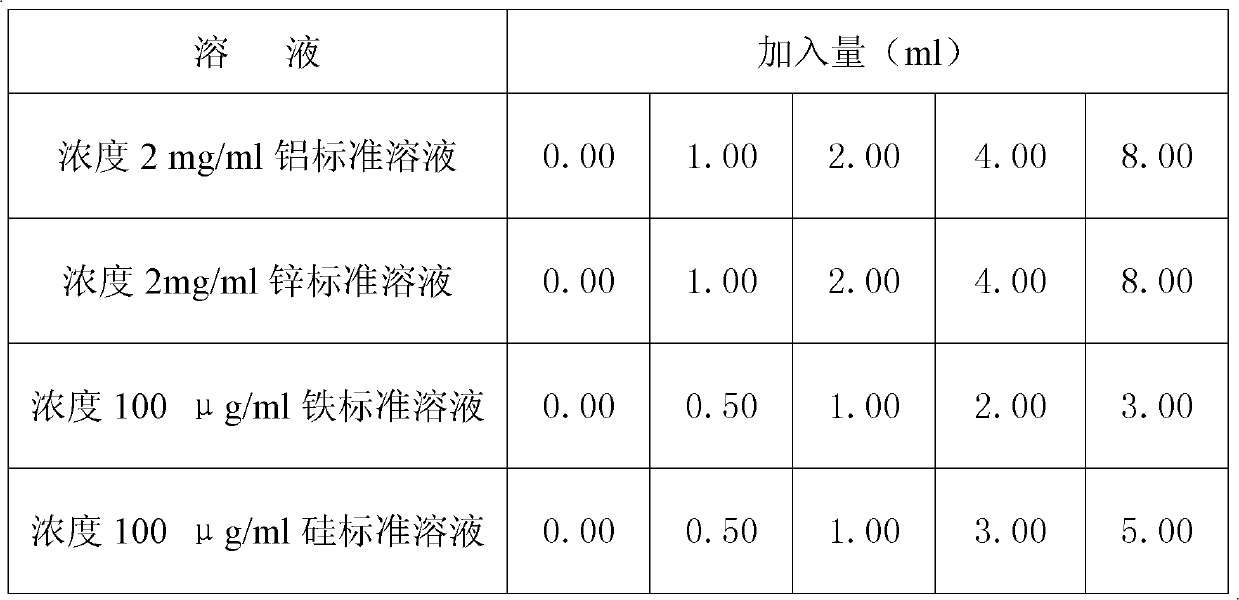

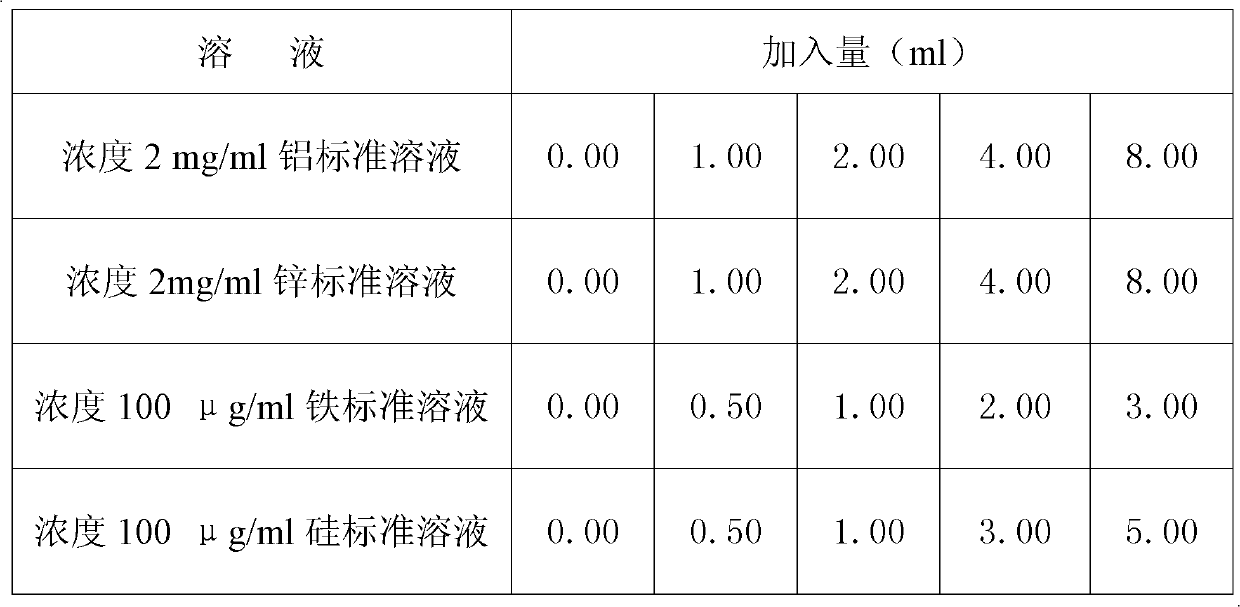

[0037] Prepare standard solutions:

[0038] a. Prepare a silicon standard solution with a concentration of 100 μg / ml: weigh 1.0698 g of silicon dioxide with a silicon weight percentage of 99.95% that has been burned at 1000 °C for 1 h in advance, cooled to room temperature in a desiccator, and placed in a solution containing 3 g of anhydrous In a platinum crucible of sodium carbonate, cover it with 1g of anhydrous sodium carbonate, first heat it at a low temperature, then heat it at a high temperature of 950°C until it is transparent, continue heating for 3 minutes, cool it, and frit it to the full depth with a plastic beaker filled with cold water, At room temperature...

Embodiment 2

[0068] 1. Preparation before analysis:

[0069] Prepare high-purity iron, absolute ethanol and hydrochloric acid with a bulk density of 1.19 g / ml.

[0070] Weigh 10 g of sodium hydroxide solid, add 100 ml of water, and mix to obtain a 10% by mass sodium hydroxide aqueous solution.

[0071] a. Prepare a silicon standard solution with a concentration of 100 μg / ml: weigh 1.0698 g of silicon dioxide with a silicon weight percentage of 99.9% after being burned at 1000°C for 2 hours in advance, and cool to room temperature in a desiccator, and place it in a solution containing 3 g of anhydrous In a platinum crucible of sodium carbonate, cover it with 2g of anhydrous sodium carbonate, first heat it at a low temperature, then heat it at a high temperature of 950°C until it becomes transparent, continue heating for 4 minutes, cool it, and frit it to the full depth with a plastic beaker filled with cold water, At room temperature, transfer to a 500ml container bottle and dilute with wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com