Gas sensing material of cuprous oxide and stannic oxide micro-nano heterogeneous medium array structure and preparing method thereof

A tin dioxide, array structure technology, applied in the direction of analytical materials, instruments, measuring devices, etc., can solve the problems of unsatisfactory gas sensitivity and inability to prepare, achieve excellent gas sensing characteristics, improve temperature dependence, and gas sensitivity Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

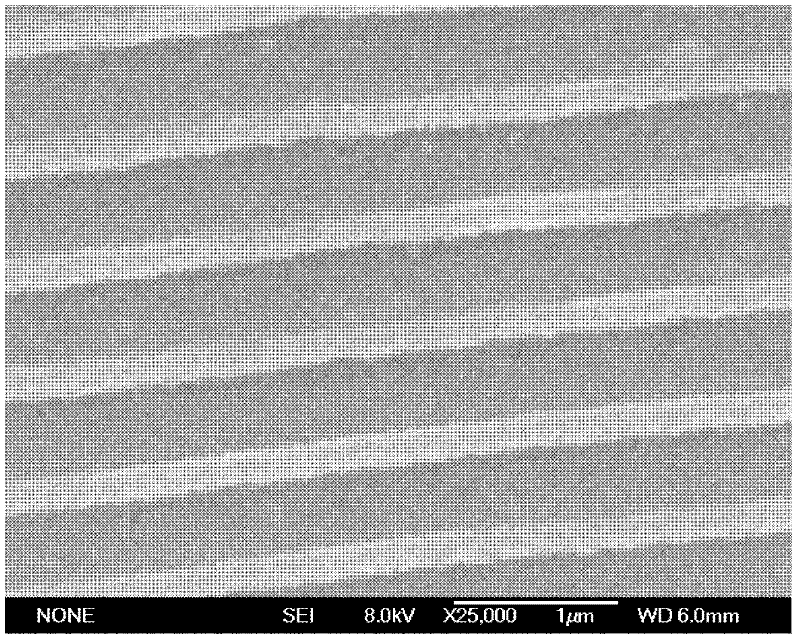

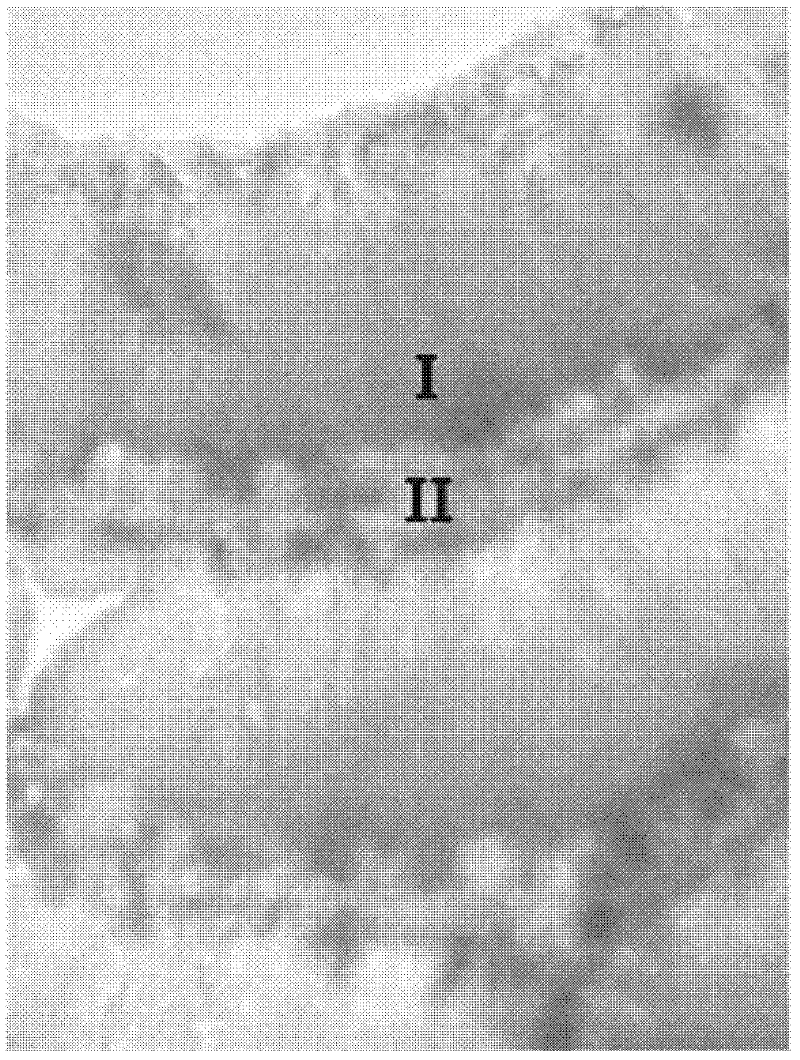

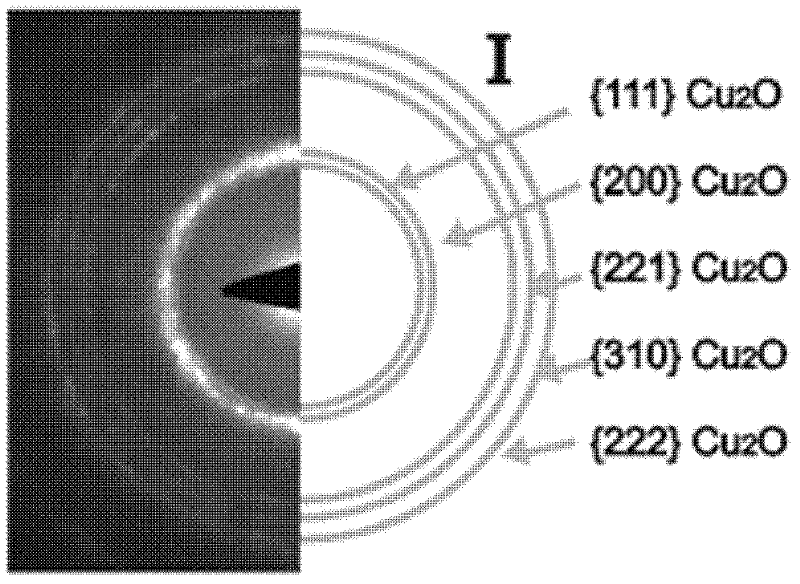

[0030] 1 Use deionized water, 0.004 moles of copper nitrate and 0.001 moles of stannous chloride to configure 50ml of electrolyte, and adjust the pH to 2.6 with nitric acid;

[0031] 2 In a temperature-controlled growth chamber, use the silicon wafer with surface oxidation treatment as the substrate, place the silicon wafer flat in the growth chamber, and then place two copper foil electrodes in parallel on the silicon wafer, and then drop the copper foil between the two electrodes electrolyte, and finally cover with a coverslip. Control the temperature at minus 4 degrees and leave it for 10 minutes;

[0032] 3 Then use the cooling element in the growth chamber to freeze the electrolyte, and naturally form a thin liquid layer of about 300 nanometers between the solidified electrolyte and the surface-oxidized substrate silicon wafer, and keep it at a low temperature of minus 4 degrees for 1 Hour;

[0033] 4 Apply a 2 Hz half-sine voltage (minimum voltage 0.4V, maximum voltage...

Embodiment 2

[0037] 1 Use deionized water, 0.004 moles of copper nitrate and 0.001 moles of stannous chloride to configure 50ml of electrolyte, and adjust the pH to 2.2 with nitric acid;

[0038] 2 In a temperature-controlled growth chamber, use the silicon wafer with surface oxidation treatment as the substrate, place the silicon wafer flat in the growth chamber, and then place two copper foil electrodes in parallel on the silicon wafer, and then drop the copper foil between the two electrodes electrolyte, and finally cover with a coverslip. Control the temperature at minus 2.6 degrees and place it for 20 minutes;

[0039] 3 Then use the cooling element in the growth chamber to freeze the electrolyte, and naturally form a thin liquid layer of about 300 nanometers between the solidified electrolyte and the surface-oxidized substrate silicon wafer, and keep it at a low temperature of minus 4 degrees for 1 Hour;

[0040] 4 Apply a 0.5Hz half-sine voltage (minimum voltage 0.4V, highest volt...

Embodiment 3

[0045] 1 Use deionized water, 0.0025 moles of copper nitrate and 0.0005 moles of stannous chloride to configure 50ml of electrolyte, and adjust the pH to 2.0 with nitric acid;

[0046] 2 In a temperature-controlled growth chamber, use the silicon wafer with surface oxidation treatment as the substrate, place the silicon wafer flat in the growth chamber, and then place two copper foil electrodes in parallel on the silicon wafer, and then drop the copper foil between the two electrodes electrolyte, and finally cover with a coverslip. Control the temperature at minus 2.6 degrees and leave it for 30 minutes;

[0047] 3 Then use the cooling element in the growth chamber to freeze the electrolyte, and naturally form a thin liquid layer of about 300 nanometers between the solidified electrolyte and the surface-oxidized substrate silicon wafer, and keep it at a low temperature of minus 4 degrees for 1 Hour;

[0048] 4 Apply a half-sine voltage of 0.2 Hz to the electrode (the lowest ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com