MgZnO solar-blind photoresistor and preparation method thereof

A photosensitive resistor, solar blind technology, applied in the field of optoelectronic information, can solve the problems of large lattice mismatch of sapphire and difficult preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

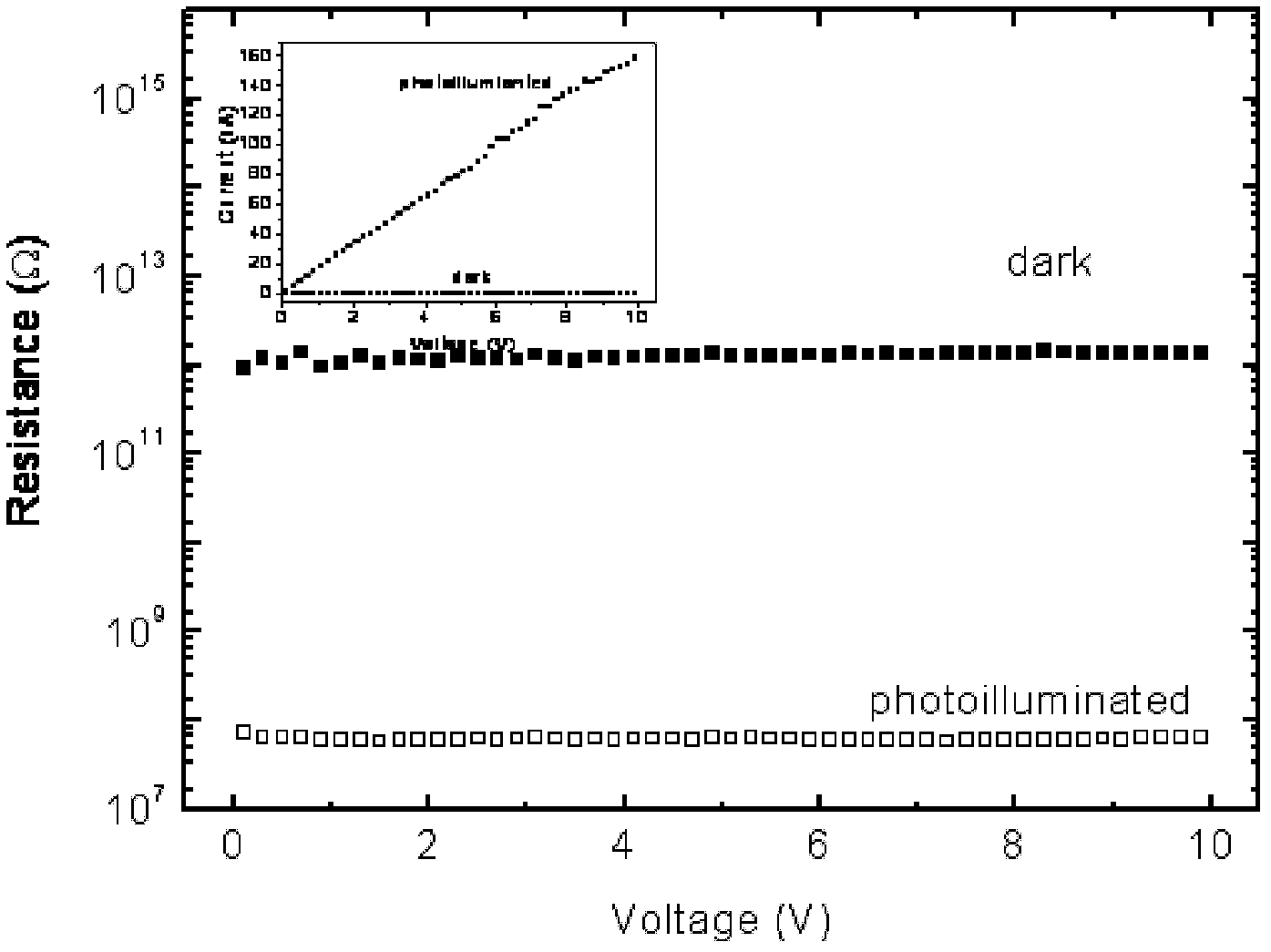

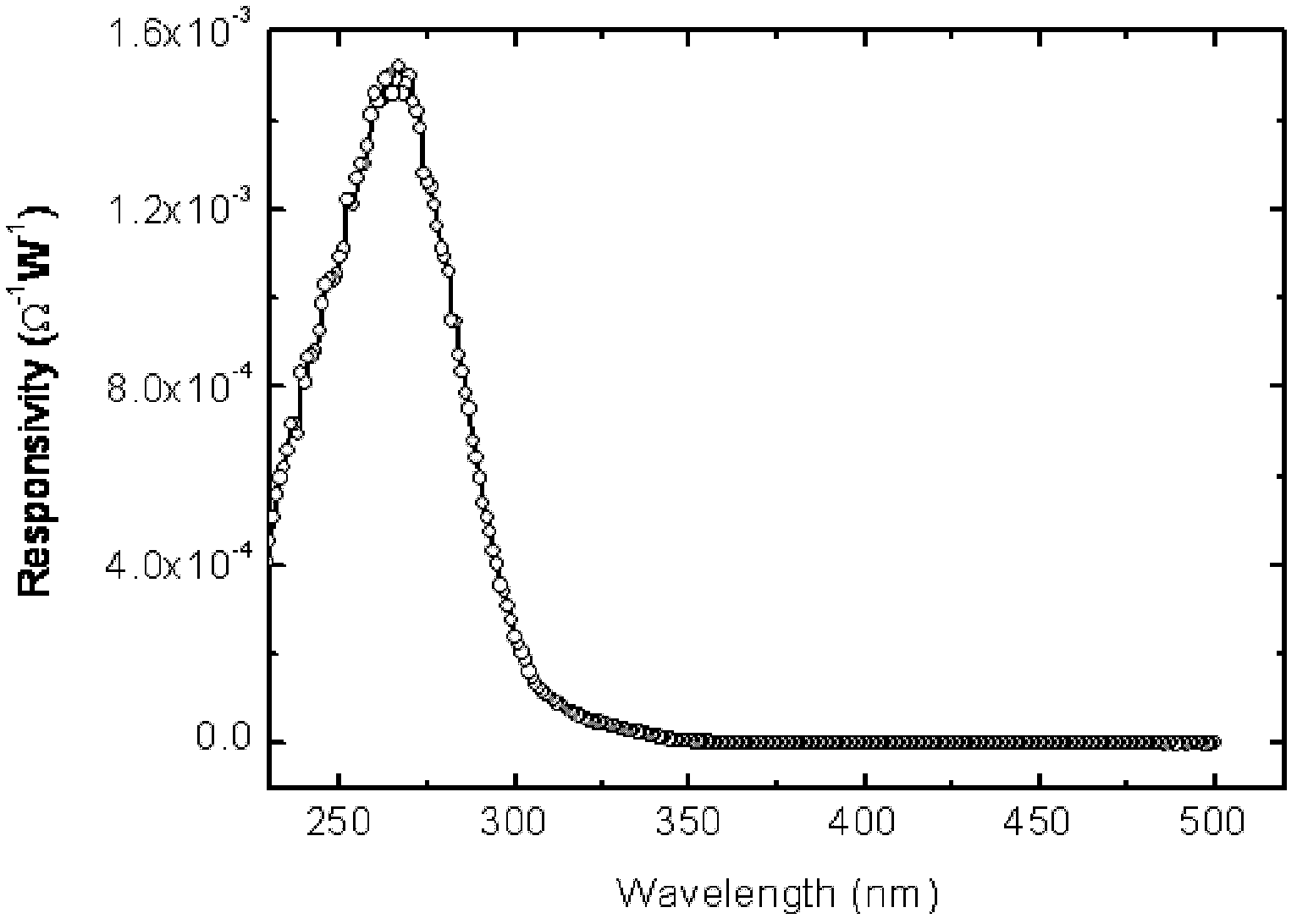

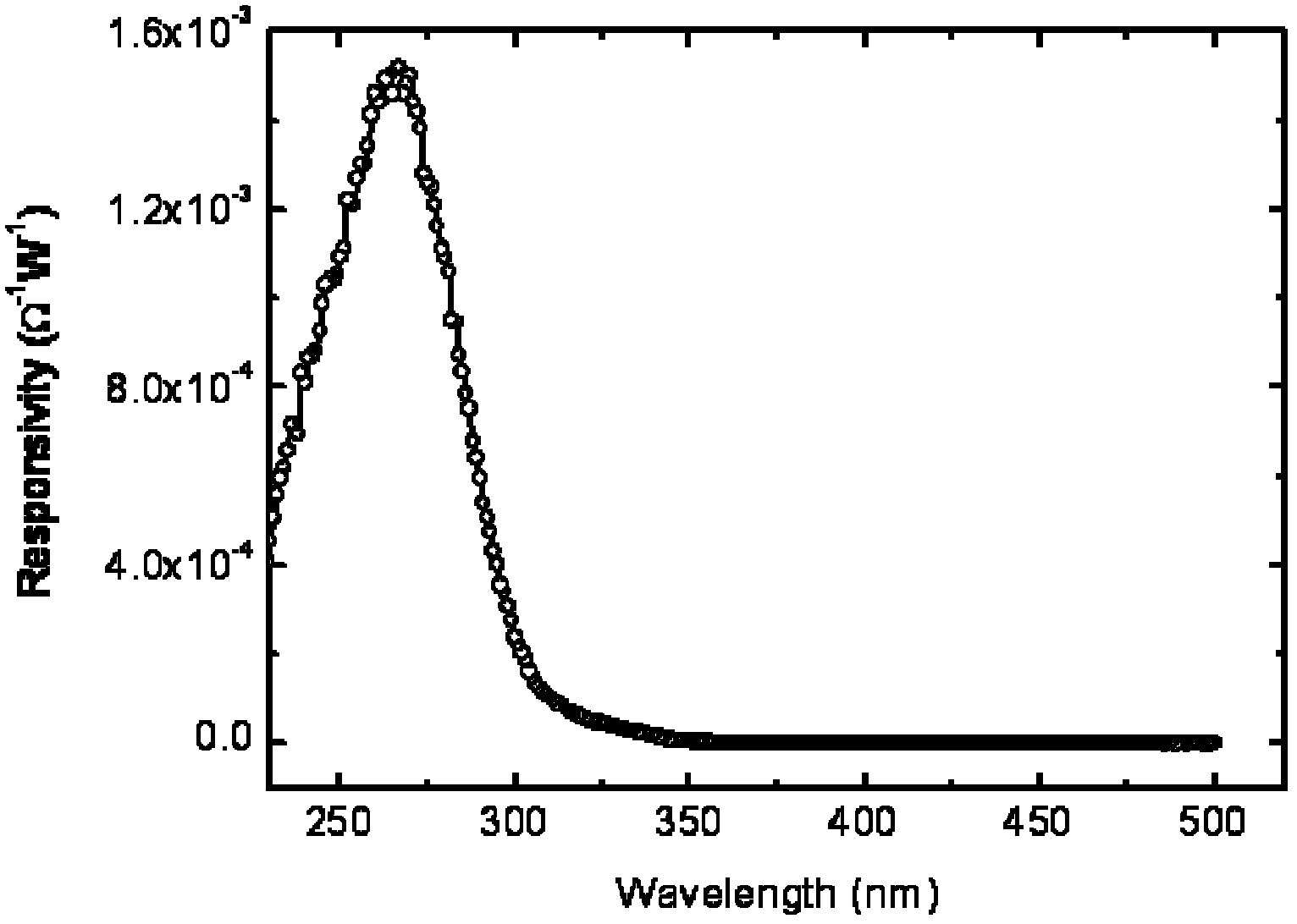

[0018] A MgZnO solar-blind photoresistor, the solar-blind photoresistor is the first layer of Mg grown on the R surface sapphire substrate with low composition Mg x Zn 1-x O transition layer, second layer Mg y Zn 1-y O transition layer, MgZnO film and electrode with high composition of Mg. The first layer of Mg x Zn 1-x X=0.16-0.20 in O transition layer, thickness is 2-10nm; Described second layer Mg y Zn 1-y Y=0.26-0.40 in O transition layer, thickness is 2-10nm; Described Mg Z Zn 1-Z Z=0.43-0.55 in the O film.

[0019] A kind of MgZnO sun-blind photoresistor preparation method 1, the steps of this method comprise:

[0020] Step 1: Pass the cleaned R-plane sapphire substrate into the MBE pre-growth chamber;

[0021] Step 2 R-plane sapphire substrate is treated in the pre-growth chamber at 750°C for 15 minutes;

[0022] Step 3 The R-plane sapphire substrate is introduced into the growth chamber, and the first layer of Mg with a thickness of 2nm is grown at a growth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com