Method for strengthening electricity generating performance of MFC (micro-function circuit) by taking excess sludge as fuel and strengthening sludge reduction by enzyme

A technology of excess sludge and electrical properties, applied in the fields of biochemical fuel cells, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of slow hydrolysis rate and limit the reduction of sludge in the electricity production characteristics of microbial fuel cells and other problems, to achieve the effect of saving costs, improving the performance of electricity production, and making full and effective use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] specific implementation plan

[0026] Below in conjunction with specific embodiment, the present invention is further explained and illustrated:

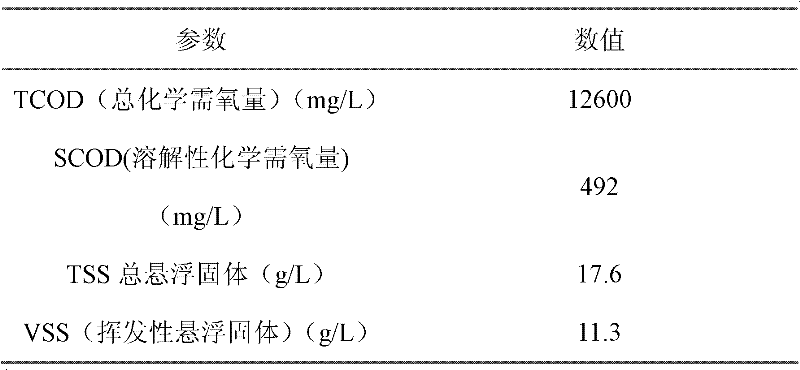

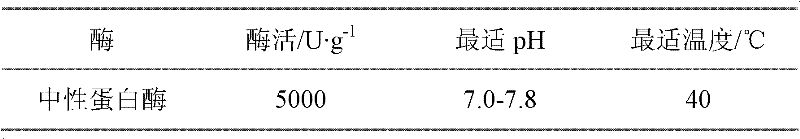

[0027] 1. Conditioning of excess sludge

[0028] Use the remaining sludge from the secondary settling tank of the sewage treatment plant, sieve (aperture 0.66mm) and settle at 4°C for 24 hours, then discard the supernatant and get concentrated sludge (to make the TCOD concentration of the remaining sludge reach 9000mg -13000mg is enough, and the specific parameters of the treated sludge in the embodiment of the present invention are shown in Table 1). The sludge was left at room temperature to restore microbial activity before starting the MFC run. The main components of sludge are carbohydrates and proteins, and the basic parameters are shown in Table 1.

[0029] Table 1 The basic parameters of the sludge used in the experiment

[0030]

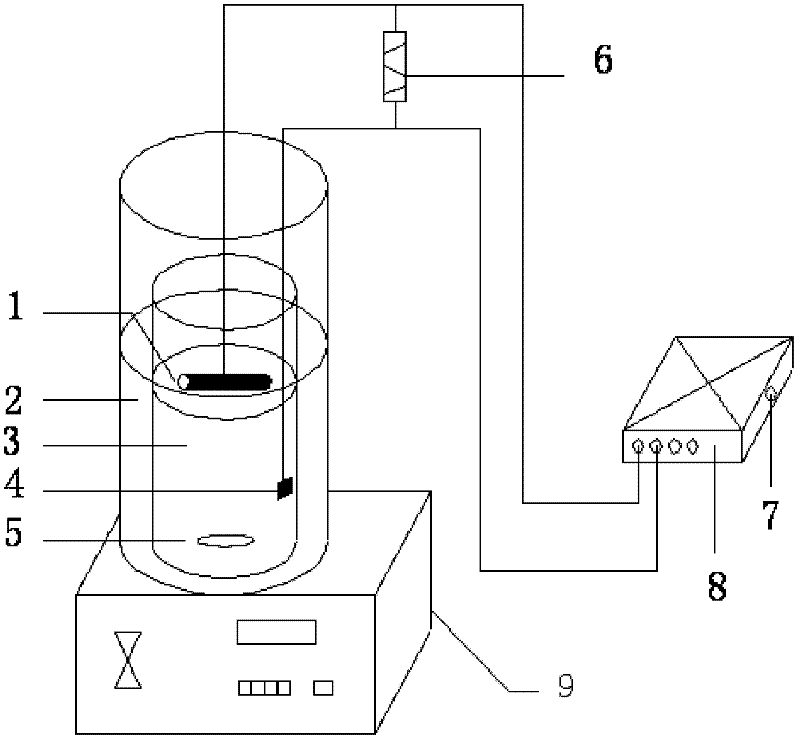

[0031] 2. Assembly and operation of MFC, see figure 1 .

[0032] Add 250ml con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com