Wound dressing with antibacterial, moisture-absorbing and calcium ion contributing functions

A technology of wound dressing and calcium ion, which is applied in the direction of absorbent pads, textiles, papermaking, medical science, etc. It can solve the problems of unrealized dressings and use on the same wound, and achieve good hygroscopicity and outstanding antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation of wound dressings containing 10% calcium alginate, 80% modified cellulose and 10% modified chitosan:

[0046] Raw material: calcium alginate fiber, fineness 7.0dtex, length 45 mm, solution A absorption rate above 1400%;

[0047] Modified cellulose with a fineness of 1.7 dtex and a length of 65 mm. The fiber is treated with carboxymethyl, and its hygroscopicity is in the fiber state. It contains 8.298 grams of sodium chloride and 0.368 grams of calcium chloride dihydrate per liter. The absorption rate of the solution (A solution) is above 1500%;

[0048] Modified chitosan, the fineness is 2.0dtex, the length is 50 mm, the fiber is processed by acylation, and its hygroscopicity is 8.298 grams of sodium chloride and 0.368 grams of calcium chloride dihydrate per liter in fiber state The absorption rate of the solution (A solution) is above 200%;

[0049] 7 grams of calcium alginate fiber, 56 grams of modified cellulose and 7 grams of modified chitosan are mix...

Embodiment 2

[0053] In order to observe the antibacterial performance of the dressing obtained in Example 1, Bacillus subtilis with an inoculation amount of about 250 μL×10E6 cfu / mL was evenly spread in a petri dish, and then the dressing obtained in Example 1 was cut into 2×2 cm and put in it , continuously cultured at a constant temperature of 37°C and observed the growth of bacteria on each plate.

[0054] figure 1 The antibacterial zone of the dressing after 2 days, 3 days, and 8 days in the Bacillus subtilis petri dish is shown, and it can be seen that the bacteriostatic effect is still maintained on the 8th day.

Embodiment 3

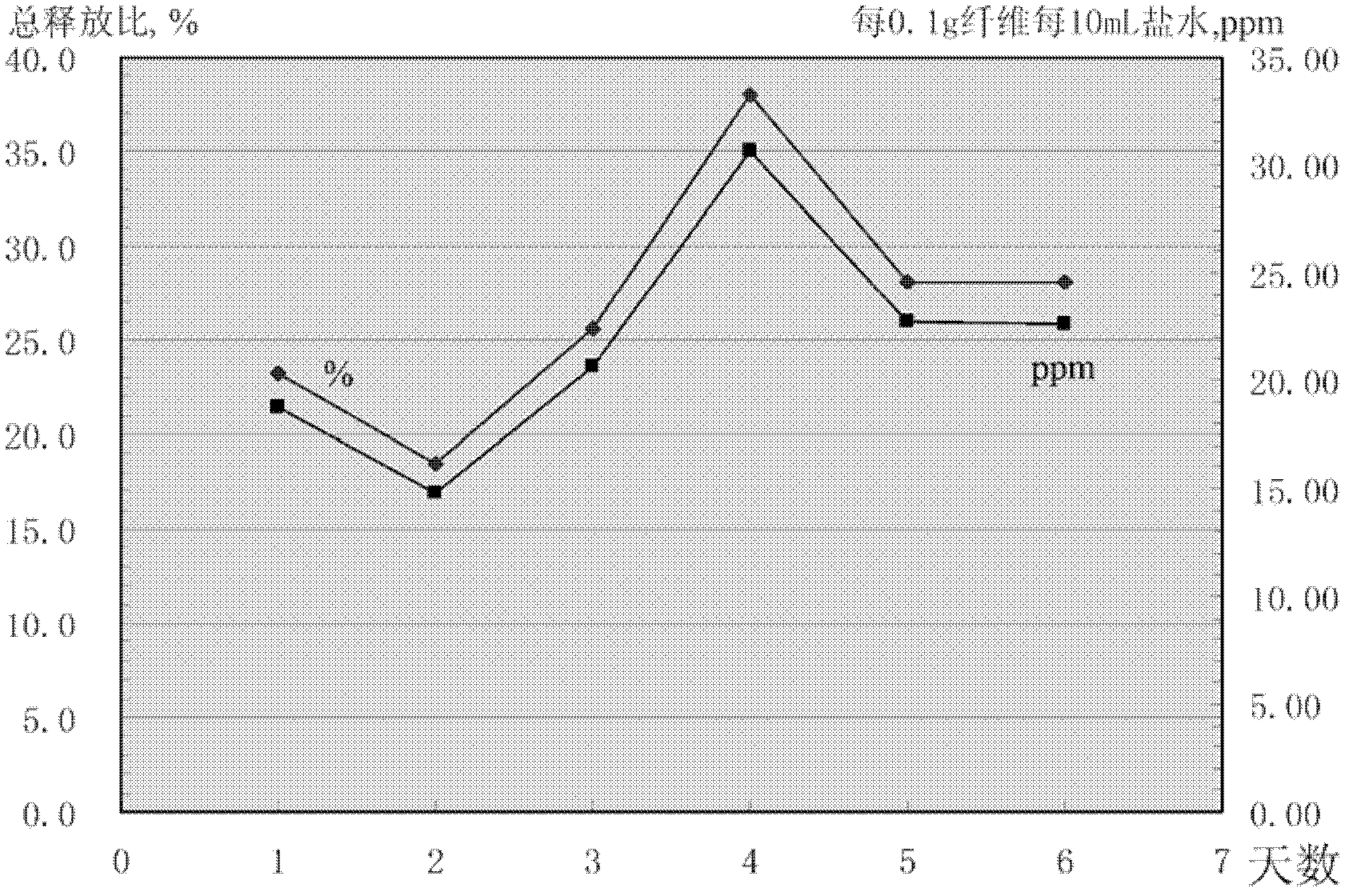

[0056] In order to observe the calcium release performance of the wound dressing obtained in Example 1, 10 mL of 0.9% NaCl solution was added to the test tube, then the dressing obtained in Example 1 was cut into 2.5 × 2.5 cm, weighed and put into it, parallel at 37 ° C Design simulation experiments from 1 day to 7 days. The release properties are obtained from the calcium content in the dressing and the calcium content in the release solution, e.g. figure 2 As shown, the release ability and time change of calcium ions, wherein the total release ratio is the ratio of the total amount of calcium in the release liquid to the calcium content in the fiber. Detected by atomic absorption spectrophotometer, the total release ratio of calcium was 26.9% on average, and the average release rate was 21.7ppm / 0.1g fiber / 10mL saline. The content of calcium alginate as a calcium source in the blend is low, and the calcium release rate is also low.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com