Method for preparing phosphomycin calcium/hexagonal mesoporous silicon/poly glycolide-co-lactide (PLGA) bone tissue stent

A technology of hexagonal mesoporous silicon and calcium phosphate is applied in the field of preparation of biomedical materials to achieve the effects of being beneficial to cell adhesion and proliferation, low cost of raw materials and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

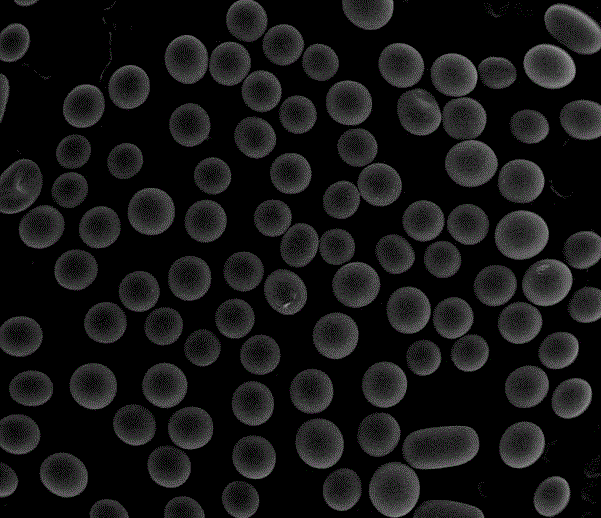

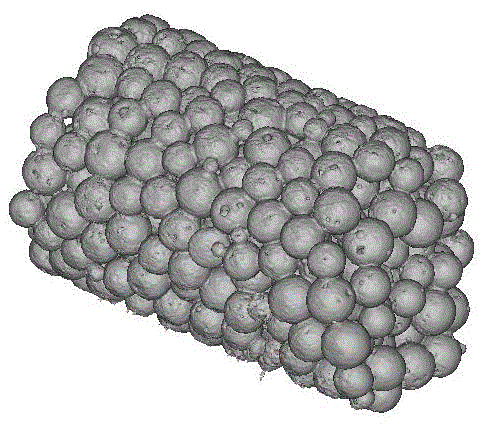

[0028] Dissolve 0.8g of PLGA in 10mL of dichloromethane to obtain a PLGA solution; mix 0.3g of calcium phosphate salt particles with 0.3g of hexagonal mesoporous silicon to obtain a calcium phosphate / hexagonal mesoporous silicon blend; mix 0.6g of phosphoric acid Calcium salt / hexagonal mesoporous silicon blend was mixed with 10mL PLGA solution evenly to obtain 10mL calcium phosphate / hexagonal mesoporous silicon / PLGA mixed solution; Stir continuously at 600r / min for 17h, wash with deionized water and freeze-dry for 24h to obtain calcium phosphate / hexagonal mesoporous silicon / PLGA microspheres; fill the microspheres into a cylindrical mold, set the temperature at 95°C for 4h, and cool After reaching room temperature, demould, the calcium phosphate salt / hexagonal mesoporous silicon / PLGA bone tissue scaffold is prepared.

Embodiment 2

[0030] Dissolve 0.5g of PLGA in 10mL of dichloromethane to obtain a PLGA solution; mix 0.2g of calcium phosphate salt particles with 0.4g of hexagonal mesoporous silicon to obtain a calcium phosphate / hexagonal mesoporous silicon blend; mix 0.6g of phosphoric acid The calcium salt / hexagonal mesoporous silicon blend was mixed evenly with 10mL PLGA solution to obtain 10mL calcium phosphate / hexagonal mesoporous silicon / PLGA mixed solution; Stir continuously at 280r / min for 5h, wash with deionized water and freeze-dry for 48h to obtain calcium phosphate / hexagonal mesoporous silicon / PLGA microspheres; fill the microspheres into a cylindrical mold, set the temperature at 80°C for 8h, and cool to room temperature, demolded, and prepared calcium phosphate / hexagonal mesoporous silicon / PLGA

Embodiment 3

[0032] Dissolve 1.0g of PLGA in 10mL of dichloromethane to obtain a PLGA solution; mix 0.3g of calcium phosphate salt particles with 0.1g of hexagonal mesoporous silicon to obtain a calcium phosphate / hexagonal mesoporous silicon blend; mix 0.4g of phosphoric acid Mix the calcium salt / hexagonal mesoporous silicon blend with 10mL PLGA solution evenly to obtain 10mL calcium phosphate / hexagonal mesoporous silicon / PLGA mixed solution; add the mixed solution to 500mL 7% polyvinyl alcohol aqueous solution, room temperature 150r / min and continuously stirred for 20 hours, washed with deionized water and freeze-dried for 72 hours to obtain calcium phosphate / hexagonal mesoporous silicon / PLGA microspheres; fill the microspheres into a cylindrical mold, set the temperature at 130°C for 6 hours, and cool to At room temperature, the mold was removed to prepare the calcium phosphate / hexagonal mesoporous silicon / PLGA bone tissue scaffold.

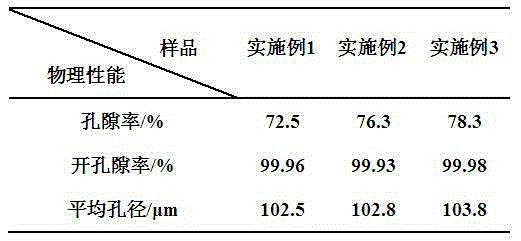

[0033]Table 1 shows the pore parameters of the calci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com