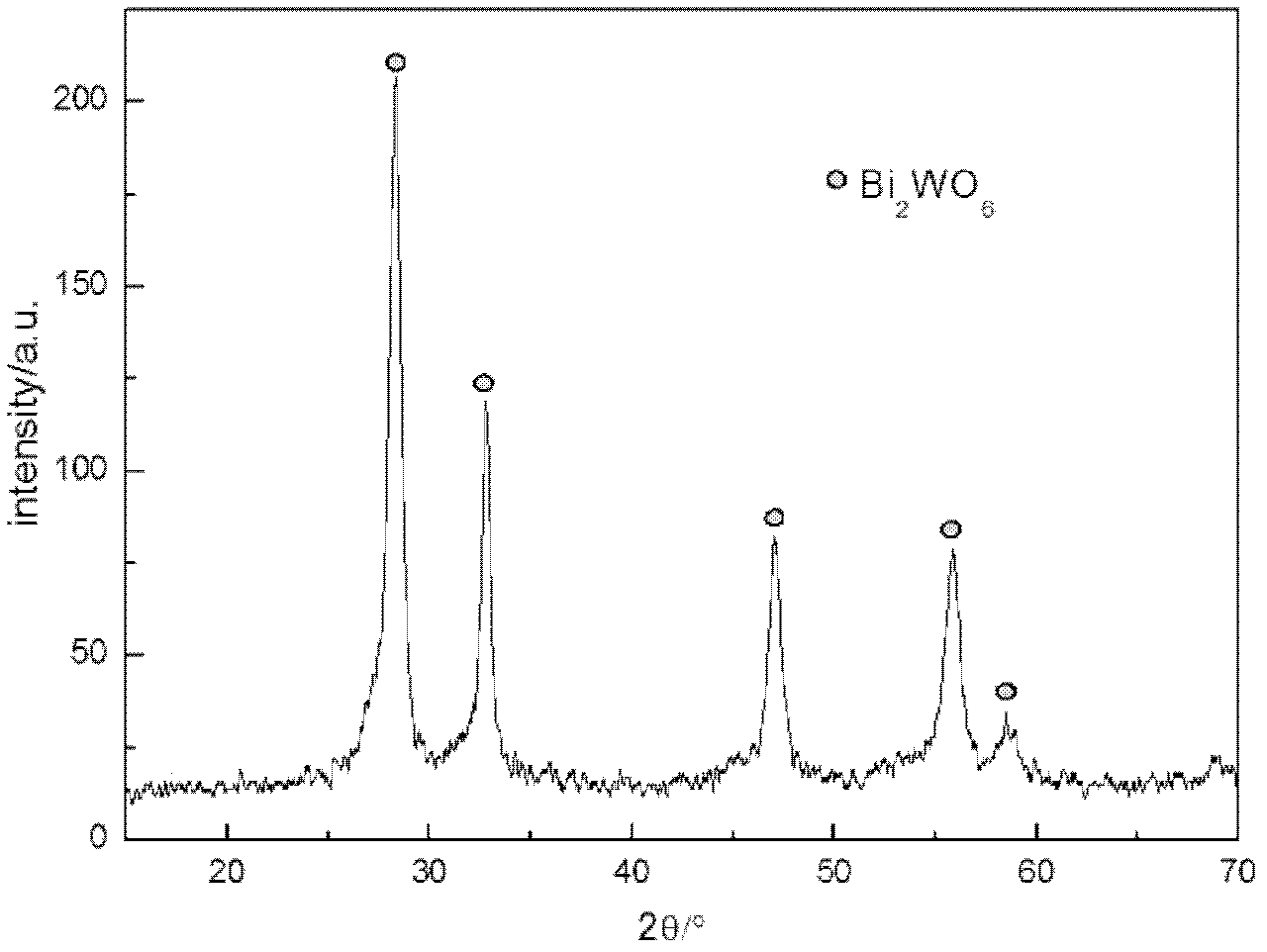

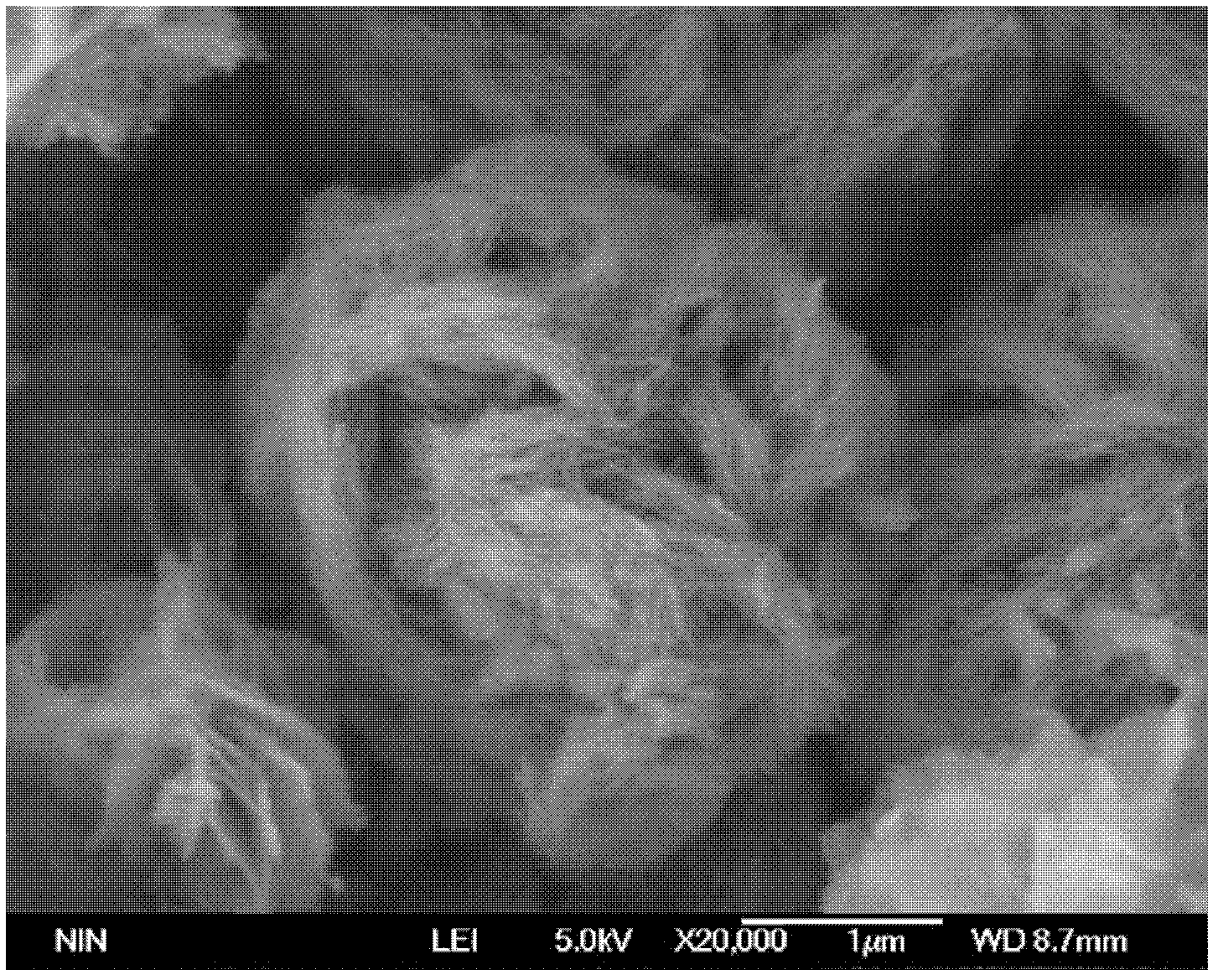

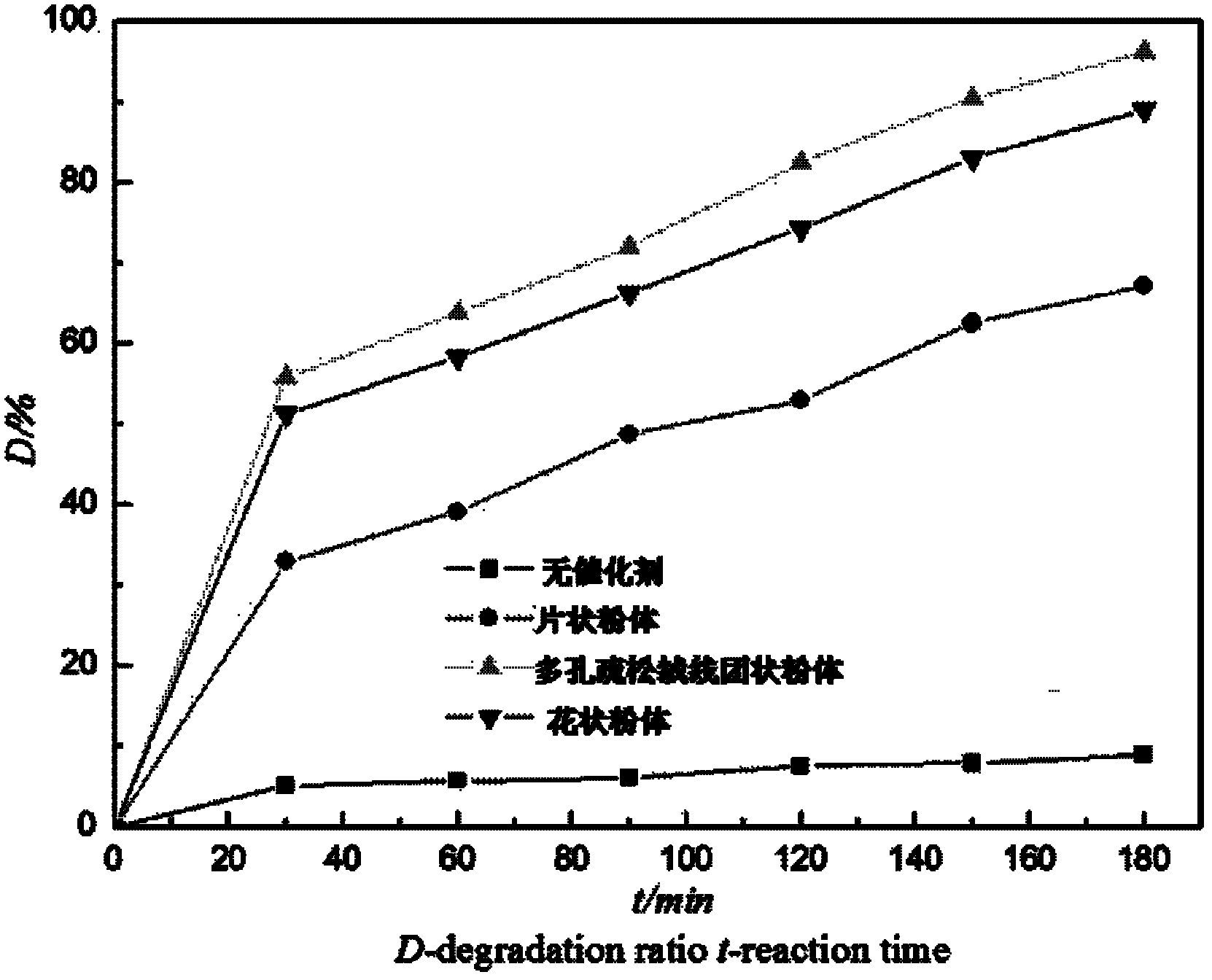

Method for preparing porous loose wool-ball-shaped bismuth tungstate powder photochemical catalyst with microwave-hydrothermal method

The technology of agglomerated bismuth tungstate and microwave hydrothermal is applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc. Simple installation, good for diffuse reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1: Weigh Bi(NO 3 ) 3 ·5H 2 O and Na 2 WO 4 2H 2 O was put into a beaker, and an appropriate amount of deionized water was added to the beaker to make Bi(NO 3 ) 3 ·5H 2 O concentration is 0.05mol / L, Na 2 WO 4 2H 2 O concentration is 0.025mol / L;

[0031] Step 2: adjust the pH to 1.6, stir magnetically at room temperature for 1 hour to mix the raw materials evenly, and obtain a precursor solution for microwave hydrothermal reaction;

[0032] Step 3: Put the precursor solution obtained in step 2 into a polytetrafluoroethylene-lined reactor, then put the reactor into a microwave hydrothermal reactor MDS-8, set the power to 300W, and set the temperature at 180°C Stop reaction after reacting for 60mins;

[0033] Step 4: After the reaction temperature drops to room temperature, take out the precipitate in the reaction kettle; wash the precipitate with water and absolute ethanol until neutral; dry it at 80°C for 10 hours, and obtain the porous and loose fluffy b...

Embodiment 2

[0035] Step 1: Weigh Bi(NO 3 ) 3 ·5H 2 O and Na 2 WO 4 2H 2 O was put into a beaker, and an appropriate amount of deionized water was added to the beaker, in which Bi(NO 3 ) 3 ·5H 2 O concentration is 0.12mol / L, Na 2 WO 4 2H 2 O concentration is 0.06mol / L;

[0036] Step 2: adjust the pH to 2.2, stir magnetically at room temperature for 1 hour to mix the raw materials evenly, and obtain a precursor solution for microwave hydrothermal reaction;

[0037] Step 3: Put the precursor solution obtained in step 2 into a polytetrafluoroethylene-lined reactor, then put the reactor into a microwave hydrothermal reactor MDS-8, set the power to 300W, and set the temperature at 160°C Stop the reaction after reacting for 50mins;

[0038] Step 4: After the reaction temperature drops to room temperature, take out the precipitate in the reaction kettle; wash the precipitate with water and absolute ethanol until neutral; dry it at 80°C for 10 hours, and obtain the porous and loose flu...

Embodiment 3

[0040]Step 1: Weigh Bi(NO 3 ) 3 ·5H 2 O and Na 2 WO 4 2H 2 O was put into a beaker, and an appropriate amount of deionized water was added to the beaker, in which Bi(NO 3 ) 3 ·5H 2 O concentration is 0.2mol / L, Na 2 WO 4 2H 2 O concentration is 0.1mol / L;

[0041] Step 2: adjust the pH to 3, stir magnetically at room temperature for 2 hours to mix the raw materials evenly, and obtain a precursor solution for microwave hydrothermal reaction;

[0042] Step 3: Put the precursor solution obtained in step 2 into a polytetrafluoroethylene-lined reactor, then put the reactor into a microwave hydrothermal reactor MDS-8, set the power at 500W, and set the temperature at 200°C Stop the reaction after reacting for 90mins;

[0043] Step 4: After the reaction temperature drops to room temperature, take out the precipitate in the reaction kettle; wash the precipitate with water and absolute ethanol until neutral; dry it at 80°C for 10 hours, and obtain the porous and loose fluffy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com