Method for preparing nanometer lithium iron phosphate in liquid phase

A lithium iron phosphate, nano-scale technology is applied in the field of directly preparing nano-scale lithium iron phosphate, which can solve the problems of difficult application and high equipment requirements, and achieve the effect of controllable size and uniform particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

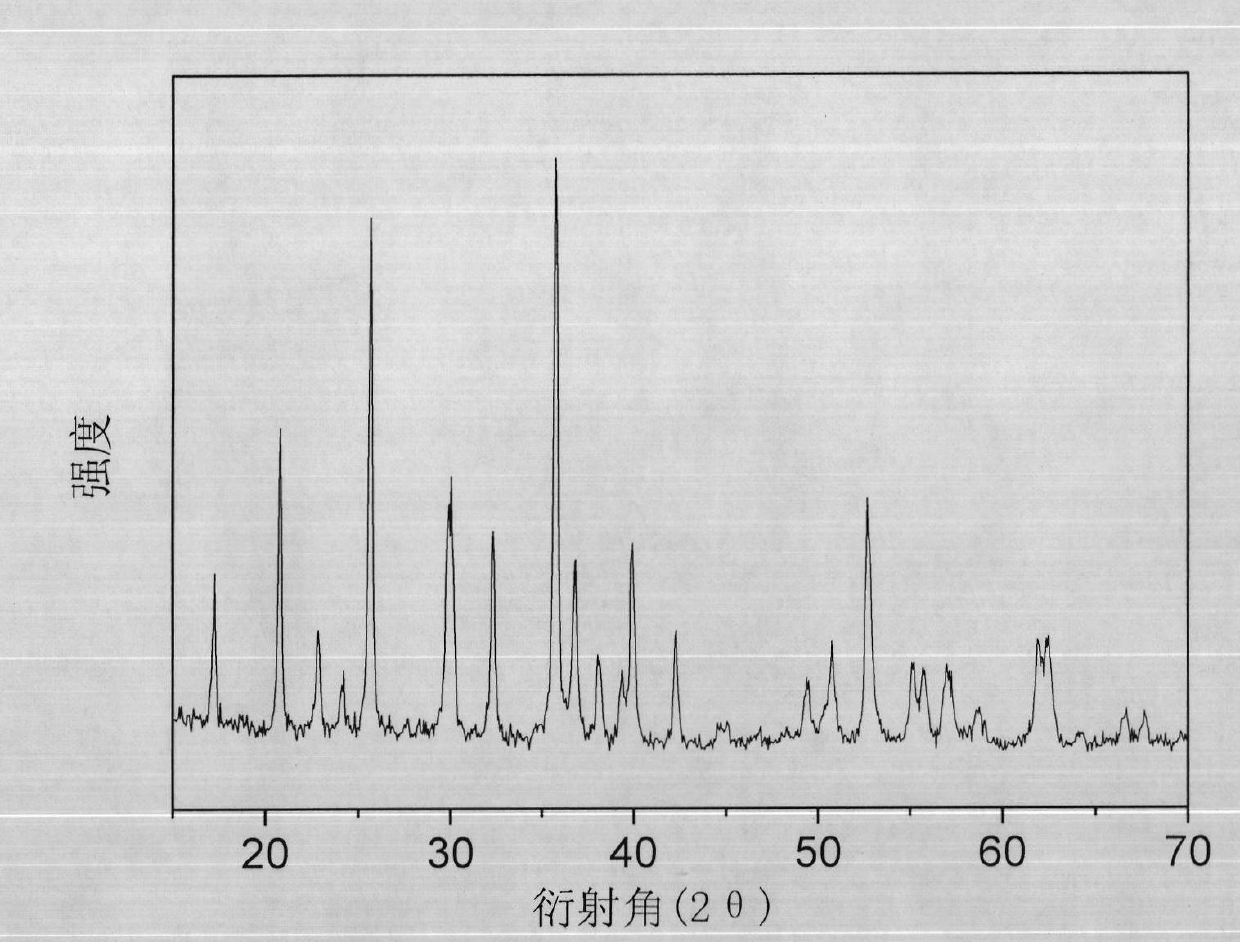

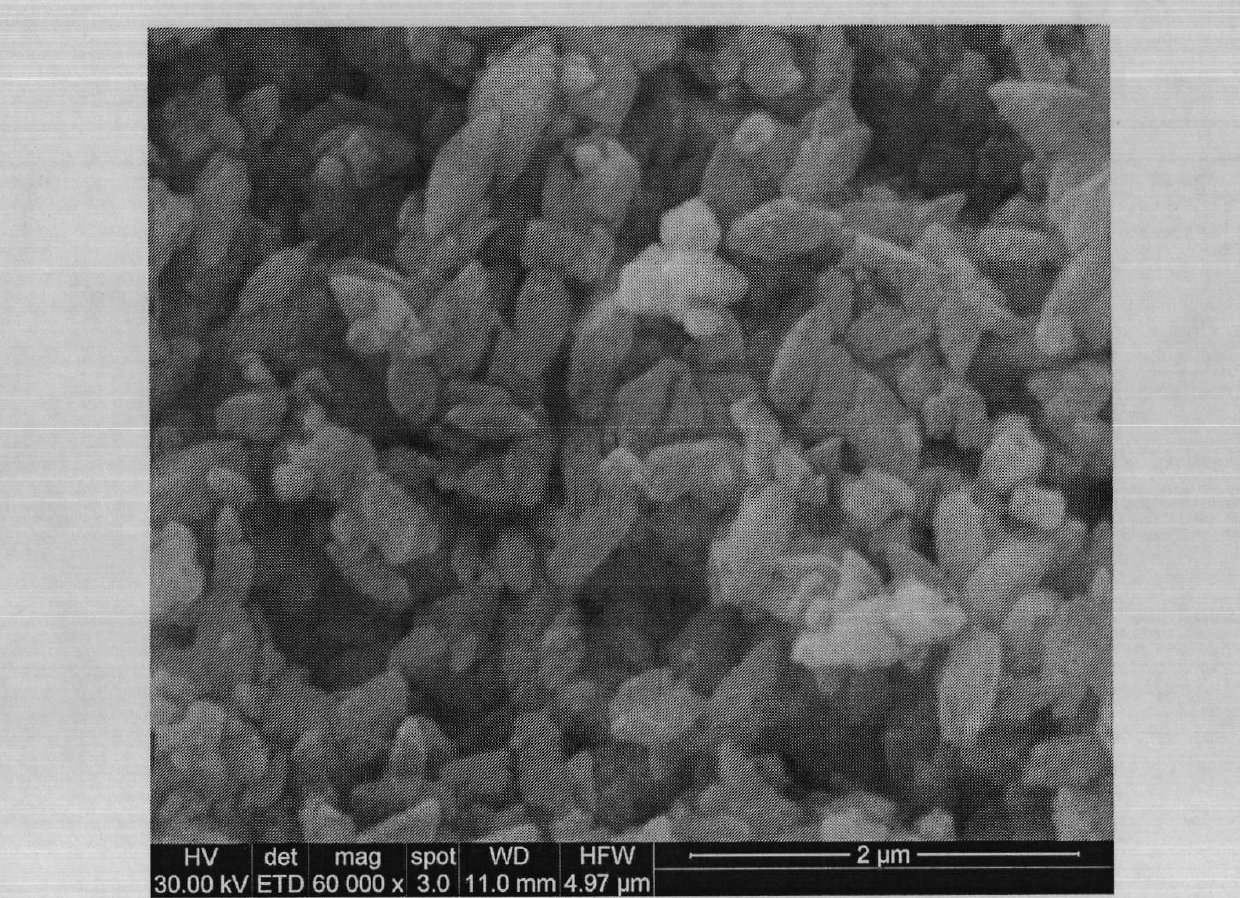

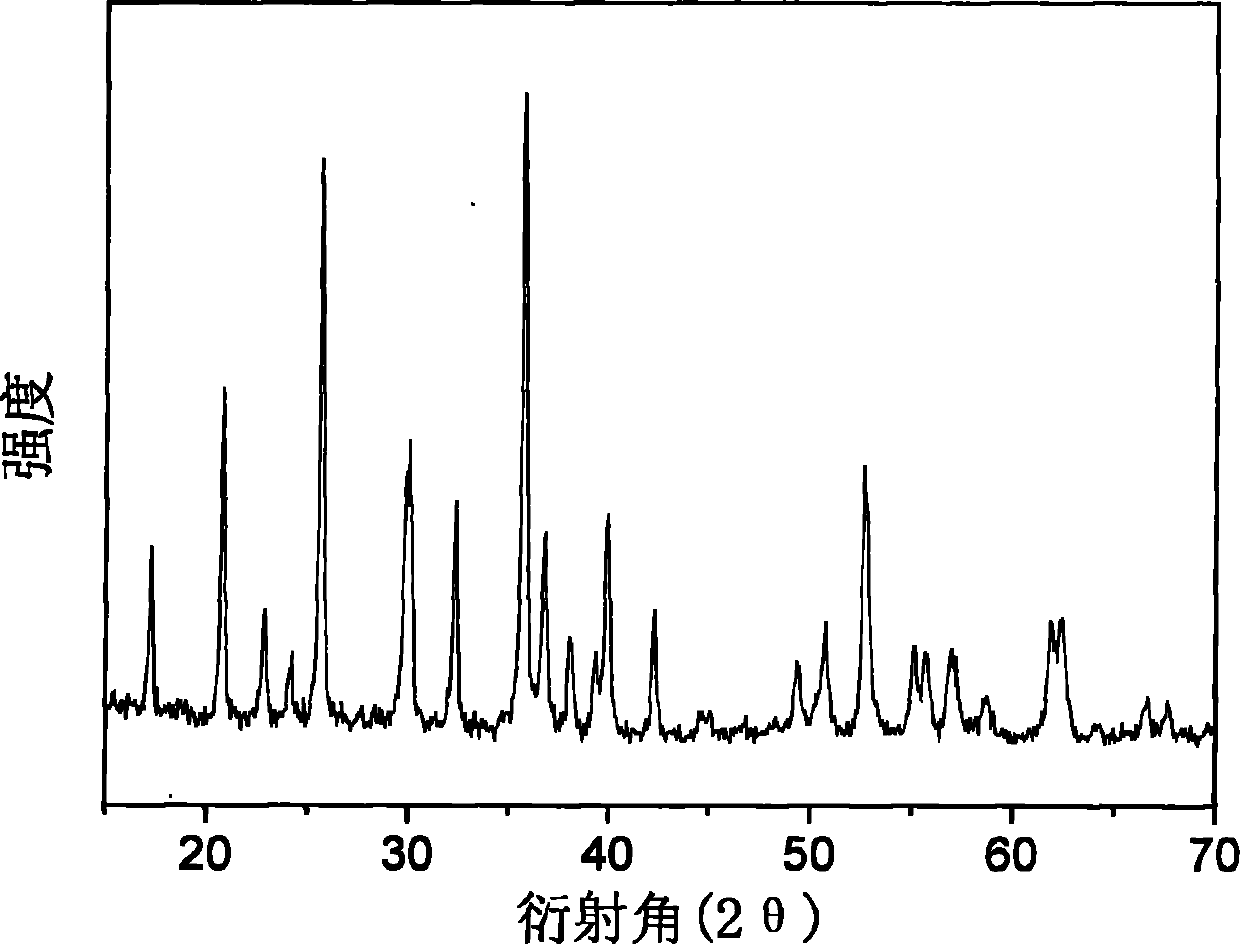

[0016] Prepare 1mol.L according to Fe:P molar ratio of 1:1 -1 100ml of mixed aqueous solution of ferrous sulfate and phosphoric acid, put the mixed solution in a 500ml reaction vessel with a reflux condenser device, add 100ml of dimethyl sulfoxide and 15ml of 0.6% polyacrylamide solution successively, slowly add 3mol .L -1 Lithium hydroxide solution until the pH of the reaction solution is 7, then heated to the boiling point of the solution (108°C) and reacted for 2 hours, the product was filtered, washed with deionized water and absolute ethanol respectively, and vacuum-dried at 100°C for 10 hours to obtain this product Invent products. The product is detected by XRD powder diffraction as olivine structure pure phase LiFePO 4 ( figure 1 ), the particle size is 40-400nm ( figure 2 ).

example 2

[0018] Prepare 1mol.L according to Fe:P molar ratio of 1:1 -1 100ml of mixed aqueous solution of ferrous sulfate and phosphoric acid, put the mixed solution in a 500ml reaction vessel with a reflux condenser device, add 200ml of dimethyl sulfoxide and 1g of sodium dodecylbenzenesulfonate successively, and slowly add 2mol.L -1 Lithium hydroxide solution until the pH of the reaction solution is 7, then heated to the boiling point of the solution (115°C) and reacted for 1 hour, the product was filtered, washed with deionized water and absolute ethanol respectively, and dried in vacuum at 100°C for 10 hours to obtain this product Invent products. The obtained sample was detected by XRD powder diffraction as olivine structure pure phase LiFePO 4 , the particle size is 40-350nm.

example 3

[0020] Prepare 1mol.L according to Fe:P molar ratio of 1:1 -1 100ml of mixed aqueous solution of ferrous chloride and phosphoric acid, put the mixed solution in a 500ml reaction vessel with a reflux condenser device, add 100ml of ethylene glycol and 0.5g of cetyltrimethylammonium bromide successively, stir slowly Slowly add 1mol.L -1 Lithium hydroxide solution until the pH of the reaction solution is 6.5, then heated to the boiling point of the solution (106°C) and reacted for 2 hours, the product was filtered, washed with deionized water and absolute ethanol, and dried in vacuum at 120°C for 8 hours to obtain this product Invent products. The obtained sample was detected by XRD powder diffraction as olivine structure pure phase LiFePO 4 , the particle size is 40-350nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com