Preparation method of amorphous state carbon nano tube

A technology of amorphous carbon and nanotubes, applied in the field of nanomaterials, can solve the problems of complex process parameters and high cost, and achieve the effects of easy process conditions, good product performance and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

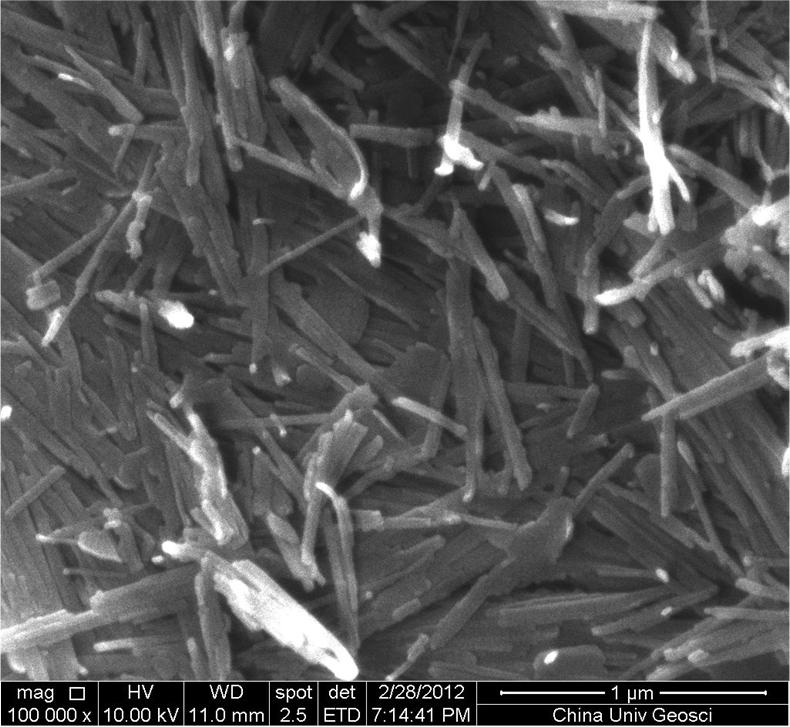

[0032] (1) Weigh 10.00g of attapulgite, add it to 150ml, 5mol / L HCl, stir magnetically at 70°C for 2 hours, then filter, wash until neutral, and bake in an oven at 105°C for 24 hours to obtain Acid-activated attapulgite.

[0033] (2) Weigh 2.50 g of the activated attapulgite and 3.00 ml of furfuryl alcohol. The two were added to 50ml of distilled water, mixed evenly, and then transferred into an autoclave, and the autoclave was placed in a homogeneous reactor at 180°C for 6 hours to prepare the precursor.

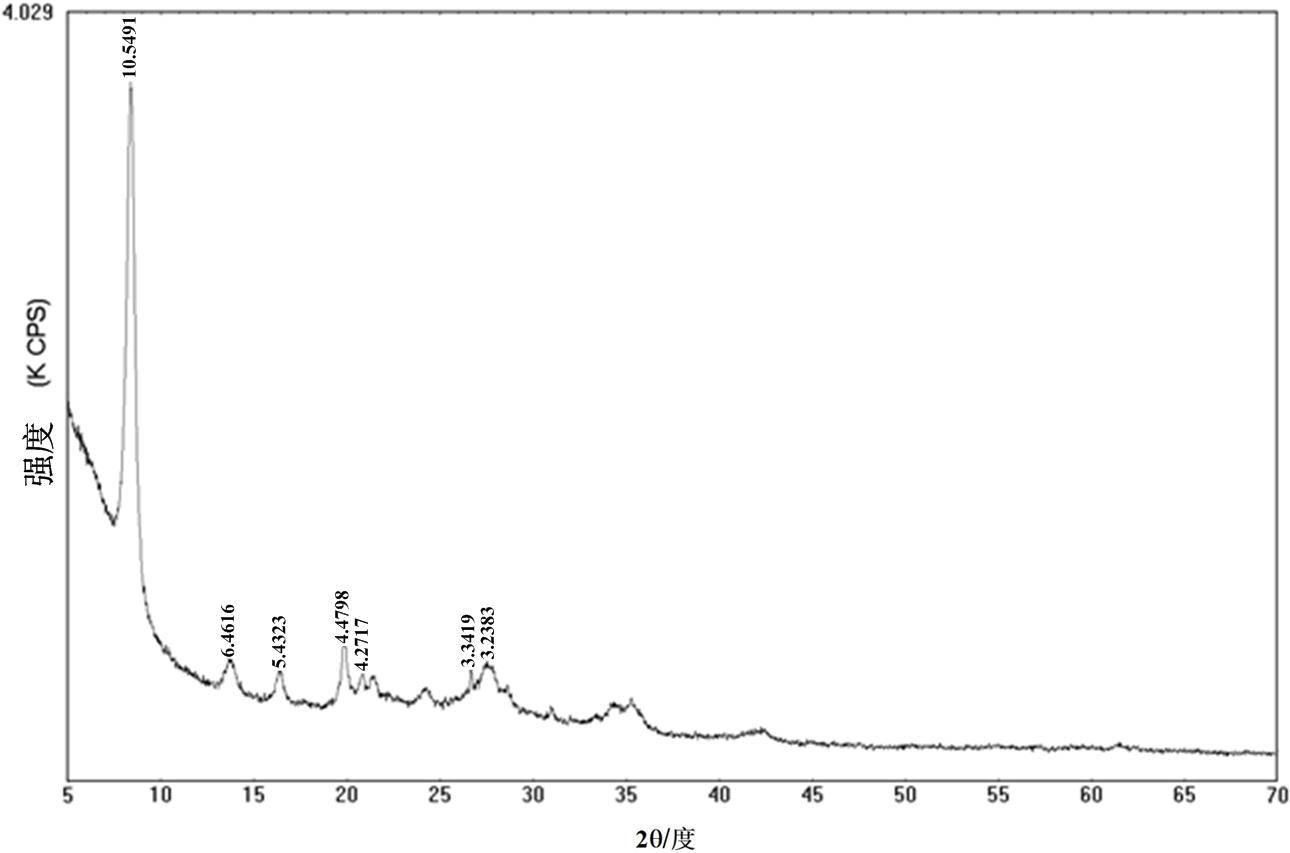

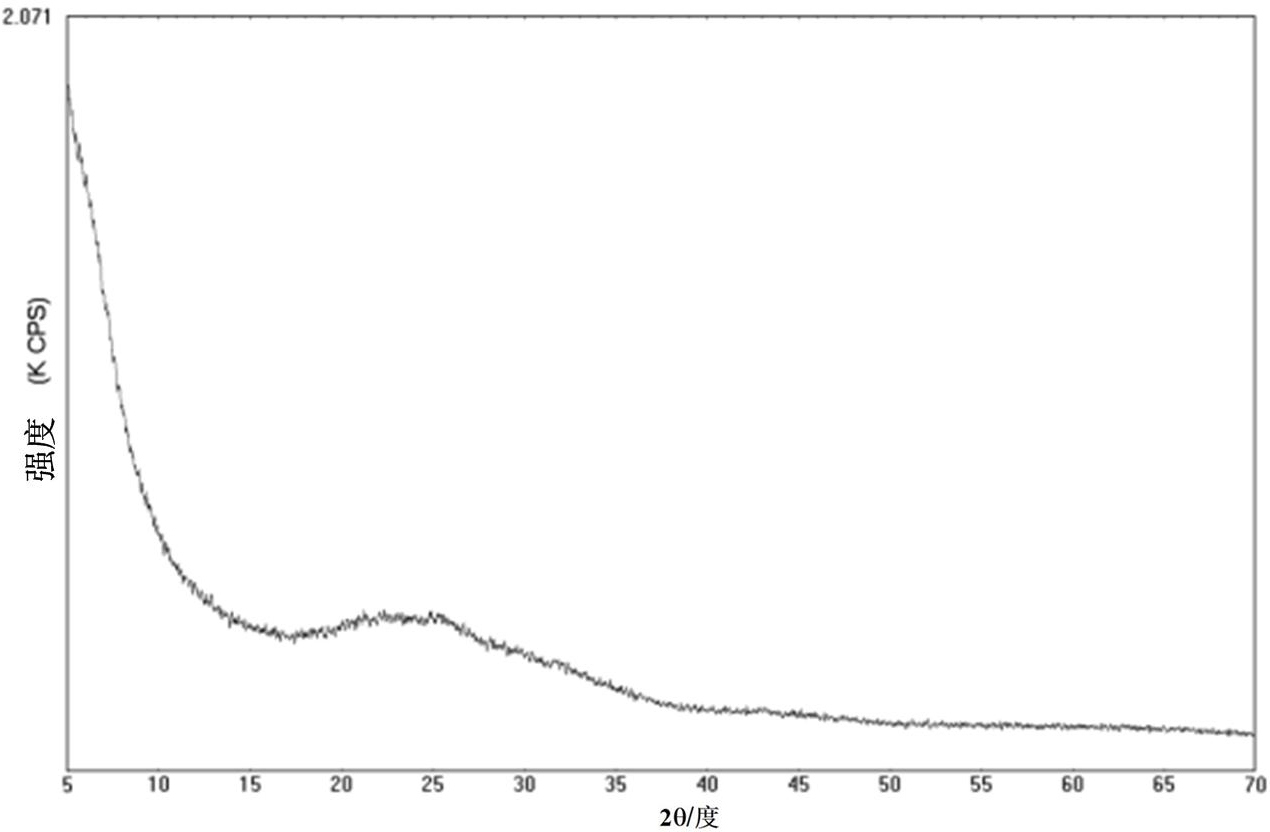

[0034] (3) Put the precursor in a porcelain boat, put the porcelain boat into a tube-type high-temperature furnace, and heat it at 800°C under N 2 Burn in air for 4 hours. After the burning, the sample was cooled to room temperature with the furnace, the sample was taken out and washed with 40wt% HF for 15 hours to remove the mineral template, and then the purified carbon was washed with concentrated HCl, and finally washed with deionized water until neutral, filtered, an...

Embodiment 2

[0037] (1) Weigh 10.00 g of attapulgite, place it in a crucible, and bake it at 200° C. for 3 hours to obtain heat-activated attapulgite.

[0038] (2) Weigh 2.50 g of the above heat-activated attapulgite and 5.00 ml of furfuryl alcohol. The two were added to 50ml of distilled water, mixed evenly, and then transferred into an autoclave, and the autoclave was placed in a homogeneous reactor at 150°C for 12 hours to prepare the precursor.

[0039] (3) Put the precursor in a porcelain boat, put the porcelain boat into a tube-type high-temperature furnace, and heat it at 600°C under N 2 Burn in air for 3 hours. After the burning, the sample was cooled to room temperature with the furnace, the sample was taken out and washed with 40wt% HF for 15 hours to remove the mineral template, and then the purified carbon was washed with concentrated HCl, and finally washed with deionized water until neutral, filtered, and placed at 100°C drying treatment to obtain amorphous carbon nanotubes...

Embodiment 3

[0042] (1) Weigh 10.00g of attapulgite, add it to 150ml, 1mol / L HNO 3 Magnetically stirred at 70°C for 2 hours, filtered, washed until neutral, and baked in an oven at 105°C for 24 hours to obtain acid-activated attapulgite.

[0043] (2) Weigh 2.00 g of the activated attapulgite and 3.00 g of glucose. Add the two into 60mL of distilled water, adjust the pH to about 8, mix well, and then move it into an autoclave, and place the autoclave in a homogeneous reactor at 180°C for 24 hours to prepare the precursor.

[0044] (3) Put the precursor in a porcelain boat, put the porcelain boat into a tube-type high-temperature furnace, and heat it at 900°C under N 2 Burn in air for 5 hours. After the burning, the sample was cooled to room temperature with the furnace, the sample was taken out and washed with 40wt% HF for 15 hours to remove the mineral template, and then the purified carbon was washed with concentrated HCl, and finally washed with deionized water until neutral, filtered,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com