Local air-water reversing upflow biological aerated filter and sewage treatment method thereof

An aerated biological filter, a local technology, is applied in the field of water treatment devices, which can solve the problems of uneven distribution of water flow resistance, uneven distribution of air and water, and unfavorable uniform film formation, so as to reduce the long generation time and improve the space. Utilization, easy disassembly and maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

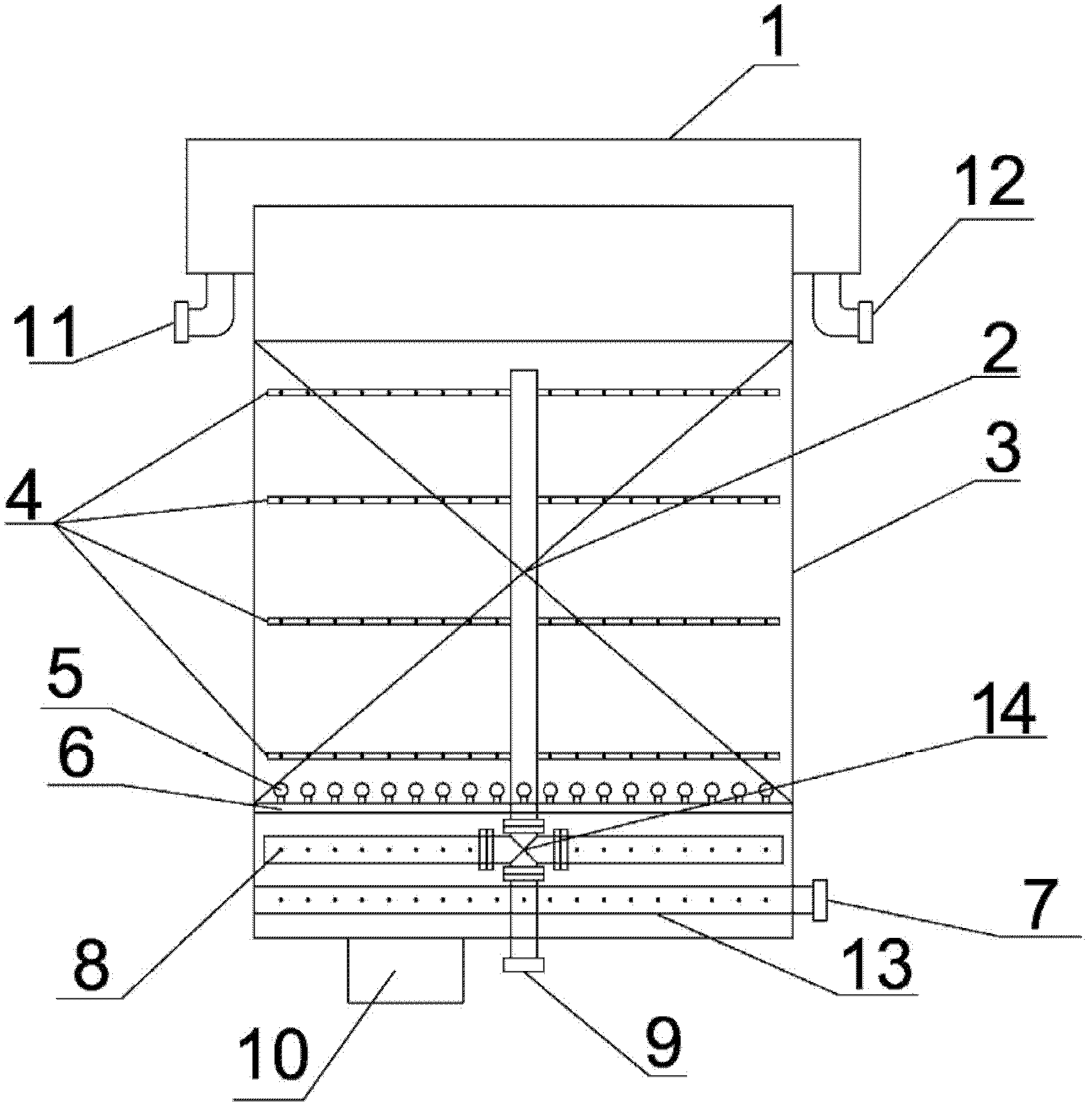

[0016] Specific Embodiment 1: In this embodiment, a partial air-water reverse upward flow biological aerated filter includes a sump 1, a filter body 3, a filter head 5, a filter plate 6, water inlet and backwash nozzle 7, Bottom aeration pipe 8, aeration main pipe 9, mud discharge outlet 10, water outlet 11, backwash outlet 12, water inlet pipe 13 and cross 14; wherein the sump 1 is arranged on the top of the filter tank body 3, and the outlet The water inlet 11 and the backwash outlet 12 are respectively arranged on the left and right sides of the sump 1, the water inlet pipe 13 is arranged at the bottom of the filter pool body 3, and the water inlet and backwash water outlet 7 are arranged at the water inlet end of the water inlet pipe 13, and the bottom The aeration pipe 8 communicates with the aeration main pipe 9, the filter plate 6 is arranged on the upper part of the water inlet pipe 13, the filter head 5 is arranged on the filter plate 6, and the mud discharge port 10 i...

specific Embodiment approach 2

[0019] Embodiment 2: This embodiment differs from Embodiment 1 in that: the needle-punched non-woven filter material has a length of 1-3 cm, a width of 1-3 cm, and a thickness of 0.2-0.8 cm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: 3 to 5 branch aeration pipes 4 are arranged along the height direction of the aeration main pipe 9 . Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com