Bi-component liquid silicone rubber and preparation method thereof

A liquid silicone rubber, two-component technology, applied in the field of silicone rubber, can solve the problems of poor strength, poor fluidity, poor operability, etc., and achieve the effect of long storage time, excellent dielectric properties, and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

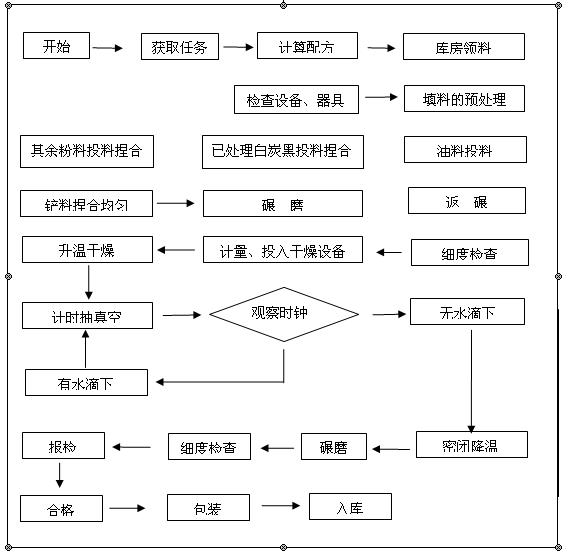

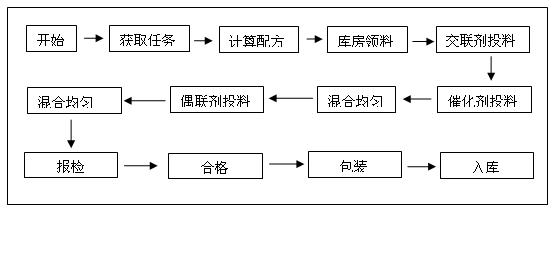

Method used

Image

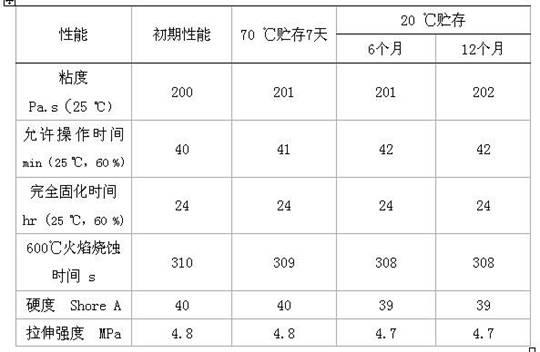

Examples

Embodiment 1

[0030] Select 90 parts of hydroxyl-terminated polysiloxane, 20 parts of fumed silica pretreated by trifunctional siloxane and D4, 40 parts of aluminum hydroxide, pretreated by trifunctional siloxane and D4 40 parts of high-temperature-resistant iron red, mix evenly in the kneader, transfer the rubber material to the three-roll machine for grinding, and then transfer to the kneader to heat up and stir, the temperature of the rubber material is 150 ° C, the vacuum degree = 0.085 Mpa. , vacuum-dried for 3 hours, sealed and cooled to room temperature. Transfer the cooled sizing material to a three-roller mill and grind it evenly to obtain component A product.

[0031] Mix 5 parts of tetraethyl orthosilicate, 1 part of organic tin carboxylate and 2 parts of aminopropyltriethoxysilane to obtain component B, which is sealed for use; mix A:B=100:4 to prepare .

[0032] Wherein, the pretreatment of trifunctional siloxane and D4 is to pass the steam of trifunctional siloxane and D4 in...

Embodiment 2

[0034] Select 110 parts of hydroxyl-terminated polysiloxane, 30 parts of fumed silica pretreated by trifunctional siloxane and D4, 50 parts of aluminum hydroxide, pretreated by trifunctional siloxane and D4 50 parts of high-temperature-resistant iron red, mix evenly in the kneader, transfer the rubber material to the three-roll machine for grinding, and then transfer to the kneader to heat up and stir, the temperature of the rubber material is 170 ° C, and the vacuum degree = 0.095 Mpa. , vacuum-dried for 4 hours, sealed and cooled to room temperature. Transfer the cooled sizing material to a three-roller mill and grind it evenly to obtain component A product.

[0035] Mix 8.5 parts of ethyl orthosilicate, 1 part of organotin chelate and 3.5 parts of aminopropyltriethoxysilane to obtain component B, which is sealed for use; mix A:B=100:6 to prepare Can.

[0036] Wherein, the pretreatment of trifunctional siloxane and D4 is to pass the steam of trifunctional siloxane and D4 i...

Embodiment 3

[0038] Select 120 parts of hydroxyl-terminated polysiloxane, 40 parts of fumed silica pretreated by trifunctional siloxane and D4, 60 parts of aluminum hydroxide, pretreated by trifunctional siloxane and D4 60 parts of high-temperature-resistant iron red, mix evenly in the kneader, transfer the rubber material to the three-roll machine for grinding, and then transfer it to the kneader to heat up and stir, the temperature of the rubber material is 190 ° C, the vacuum degree = 0.1 Mpa. , vacuum-dried for 5 hours, sealed and cooled to room temperature. Transfer the cooled sizing material to a three-roller mill and grind it evenly to obtain component A product.

[0039] Mix 12 parts of ethyl orthosilicate, 3 parts of organotin chelate and 5 parts of aminopropyltriethoxysilane evenly to obtain component B, which is sealed for use; mix A:B=100:7 to prepare Can.

[0040] Wherein, the pretreatment through trifunctional siloxane and D4 is that the steam of trifunctional siloxane and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com