Waterborne camouflage paint and preparation method thereof

A paint and water-based technology, applied in the field of water-based camouflage paint and its preparation, can solve the problems of being inflammable and explosive, unfavorable for transportation and storage, harmful to the health of construction workers, etc., and achieves excellent anti-corrosion performance, excellent anti-corrosion ability, convenient transportation and stored effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

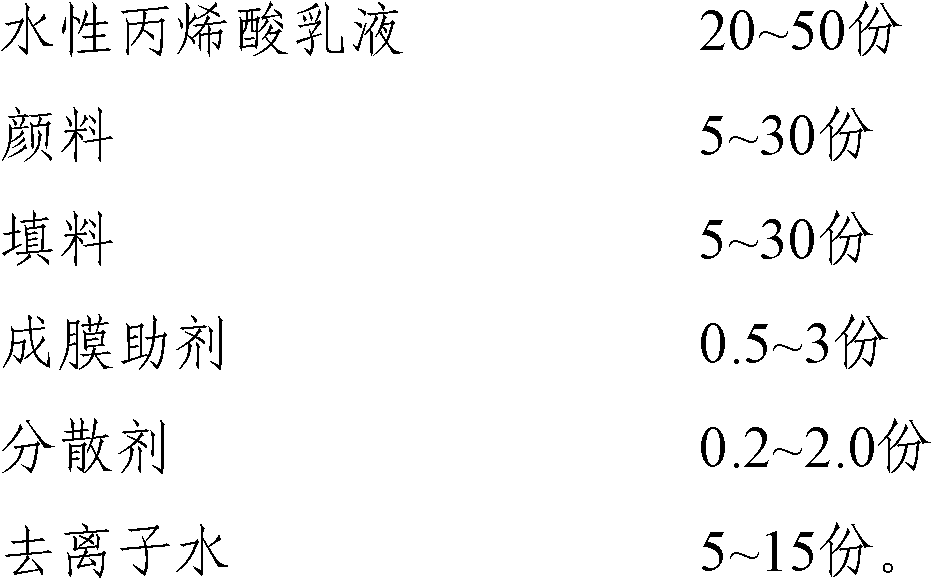

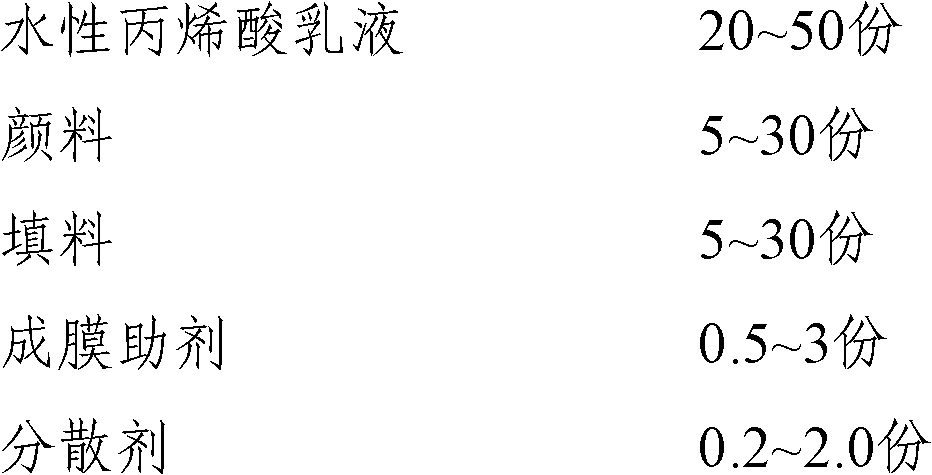

Method used

Image

Examples

Embodiment 1

[0026] Put 35Kg polystyrene-acrylate, 1Kg sodium methylene bis-naphthalene sulfonate into the dispersing kettle in turn and stir evenly; then put 5Kg iron oxide red, 10Kg iron oxide black, 5Kg iron oxide yellow, 5Kg iron trioxide, 5Kg three Ferric chloride, 10Kg barium sulfate, and 10Kg barium carbonate are ground to a fineness of less than 50 microns; finally, 2KgDPNB (U.S. Dow Chemical), 1.5KgAMP95 (U.S. ANGUS Chemical Company), 1.5KgBYK-425, 1.5KgBYK-024, and 12Kg are put into The water-based camouflage paint was prepared evenly by ionic water dispersion, and the performance test is shown in Table 1.

Embodiment 2

[0028] Put 50KgHG-54D (Rohm and Haas), 0.2KgBYK-190 into the dispersing tank in turn and stir evenly; then put in 5Kg iron oxide red, 5Kg iron oxide yellow, 5Kg copper sulfate, 5Kg mica and grind to a fineness of less than 50 microns; finally Put 0.5Kg diethylene glycol monomethyl ether, 0.5Kg AMP95 (U.S. ANGUS chemical company), 0.5Kg fumed silica, 0.5Kg BYK-024, 5Kg deionized water to disperse evenly to prepare water-based camouflage paint, performance test as shown in Table 1 Show.

Embodiment 3

[0030] Put 20Kg polyacrylic acid-carbamate, 2Kg sodium methylene bismethylnaphthalene sulfonate into the dispersing kettle in turn and stir evenly; then throw in 5Kg iron oxide red, 5Kg copper sulfate, 5Kg copper chloride, 5Kg iron oxide, 5Kg ferric chloride, 5Kg ferric chloride, 5Kg calcium carbonate, and 5Kg barium carbonate are ground to a fineness below 50 microns; finally, 3Kg film-forming aid (diethylene glycol monobutyl ether), 1.5Kg AMP95 (U.S. ANGUS chemical Company), 1.5Kg diatomaceous earth, 1.2Kg polydimethylsiloxane, 10Kg deionized water are uniformly dispersed to prepare water-based camouflage paint, and the performance test is as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com