Fire retardant coating

A technology of fireproof coatings and pigments, applied in fireproof coatings, epoxy resin coatings, coatings, etc., can solve the problems of high cost, incomplete functions, and poor performance of fireproof coatings, and achieve good fireproof performance and good acid and alkali resistance , The effect of maintaining durability and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Based on 100kg of product, 12kg of cellulose ether, 15kg of FEVE fluorocarbon resin, 13kg of glass beads, 20kg of pigment, 7kg of ammonium polyphosphate, 6kg of curing agent, 25kg of phenolic propane epoxy resin, 5kg of pentaerythritol, 5kg of expanded graphite, and the rest are solvents . Solvent a is preferably isopropyl acetate, and solvent b is preferably n-butanol. The curing agent is dimethylaniline.

[0027] Step 1: Mix glass beads, pigments, ammonium polyphosphate, curing agent, and solvent a, and after stirring evenly, perform high-speed grinding to a fineness of 15-20 μm to obtain a color paste;

[0028] Step 2: Mix cellulose ether, FEVE fluorocarbon resin, phenolic propane epoxy resin and solvent b, stir evenly, add the color paste prepared in step 1, disperse at high speed for 15-20 minutes, and filter, which is the present invention product.

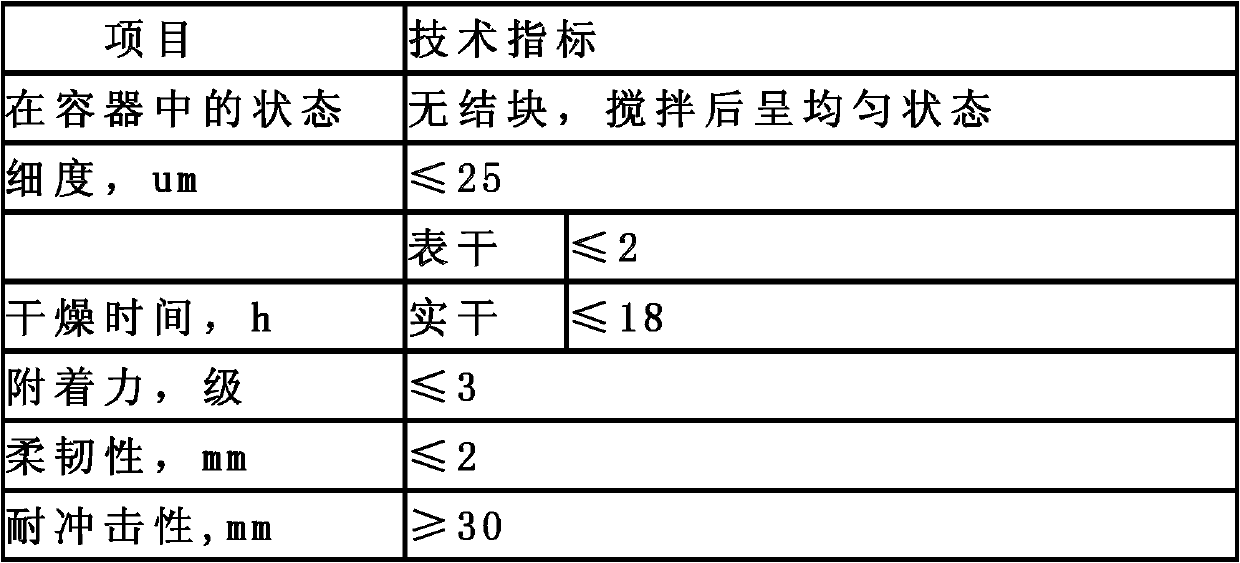

[0029] Product performance testing results are shown in the table below

[0030]

[0031]

Embodiment 2

[0033] The curing agent is 2,4-dihydroxybenzophenone, and the remaining raw materials and preparation methods are as in Example 1. Except for the drying time, the product and performance are the same as in Example 1. Due to the use of light curing agent, the curing is rapid and the curing time is less than 20 seconds. .

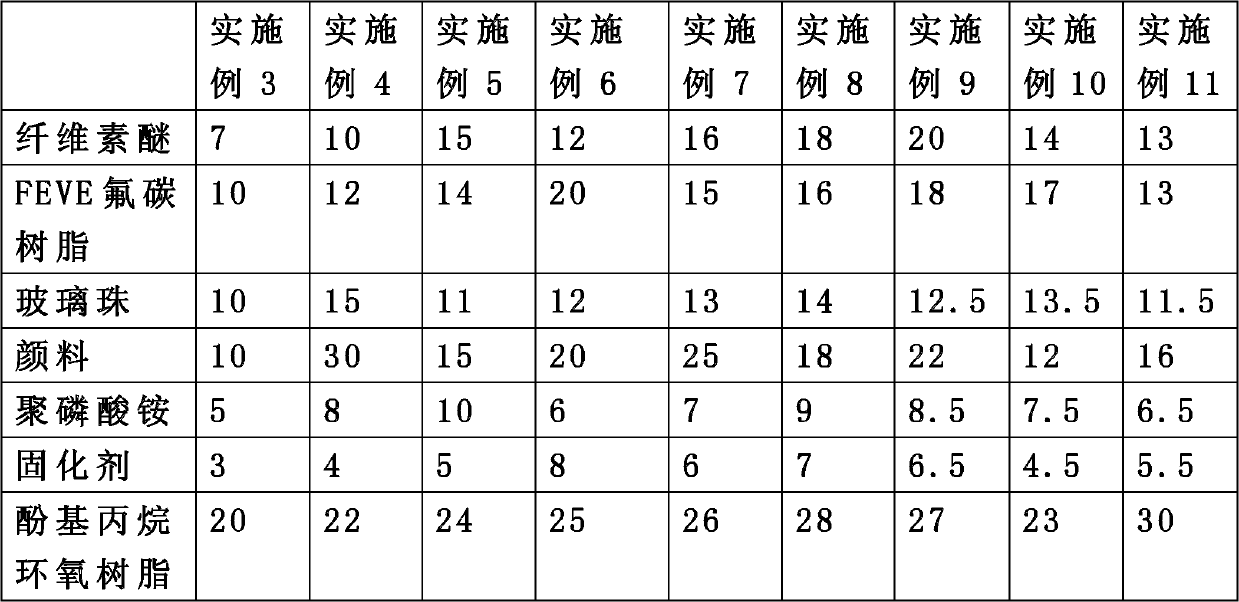

Embodiment 3-11

[0035] Prepare 100kg product according to the method described in embodiment 1, formula is as follows, curing agent is dimethyl aniline.

[0036]

[0037]

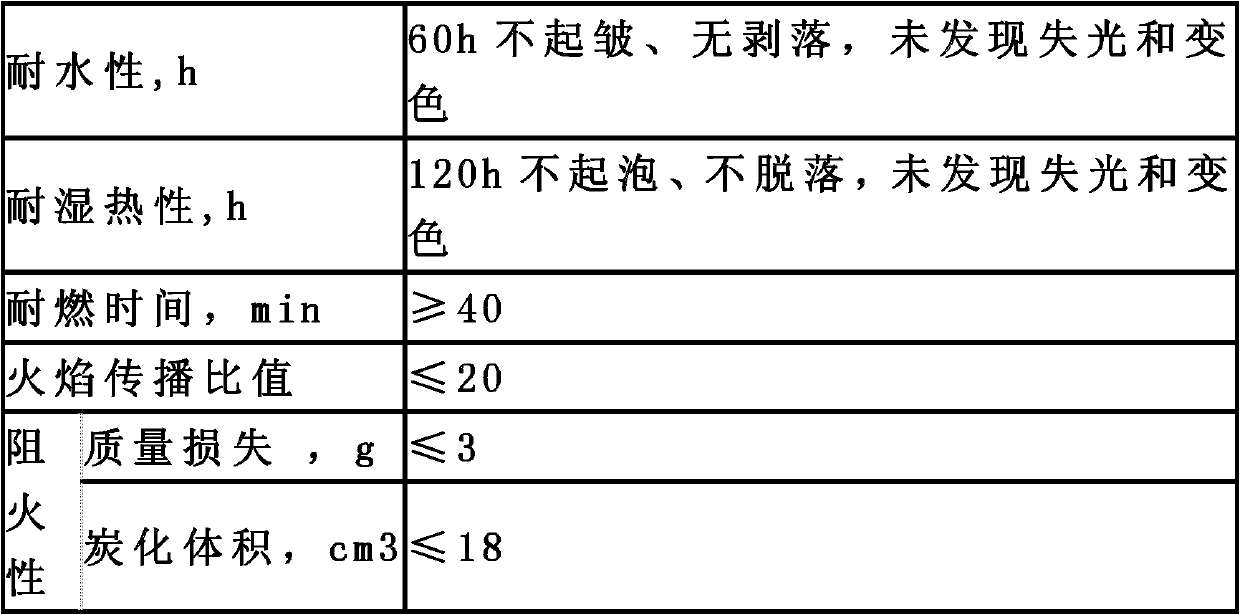

[0038] Embodiment 3-11 performance index is as follows:

[0039]

[0040] Technical project introduction:

[0041] Flame-resistant time: Under the specified substrate and specific combustion conditions, the time (min) required for the temperature of the back-fired surface of the test plate to reach 220°C or for the test plate to penetrate.

[0042] Flame spread ratio: when the flame spread ratio of the asbestos board is "0" and the flame spread ratio of the oak wood board is "100", the surface flame spread characteristic data of the tested material.

[0043] Fire retardant performance: Expressed by combustion mass loss and carbonization volume.

[0044] Mass loss: the mass difference (g) of the test piece before and after burning under the specified coating ratio and specified combustion conditions.

[0045] Ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com