Microalgae cultivation system and method

A breeding system and microalgae technology, applied in the fields of energy, health care products, food, and medicine, can solve the problems of inability to realize industrialized production, unfavorable industrialized production, and low production efficiency, and meet the needs of industrialized large-scale microalgae cultivation. Implementation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

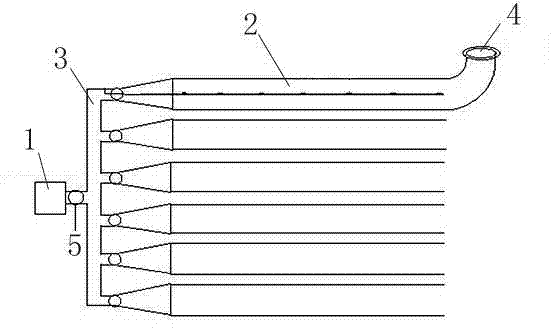

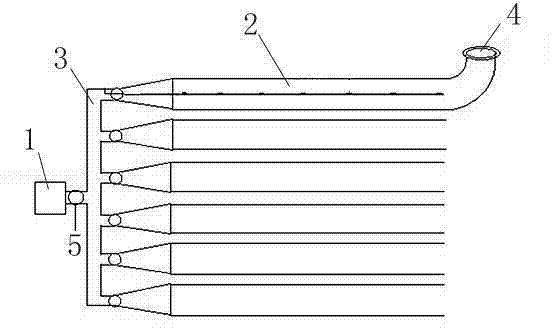

Embodiment 1

[0032] Calculated on the basis of 1 hectare of farming area

[0033] 1. The relevant membrane system parameters are selected as follows:

[0034] 1 The length of a single tubular membrane is 10m;

[0035] 2 The membrane inner diameter of the membrane culture system is 0.45m;

[0036] 3 The film thickness is 0.15mm;

[0037] 4 The distance between the membrane tubes is 0.2m;

[0038] 5 A culture system is composed of 6 tubular membranes.

[0039] A culture membrane system covers an area of about 37m 2 , volume 9.54 m 3 , the land can accommodate 270 membrane systems, with a breeding volume of 2575.8 m 3 .

[0040] Two farming methods

[0041] 1 Level the breeding site, remove all kinds of sharp objects (including gravel, glass, etc.), and lay a black heat-absorbing mat;

[0042] 2. According to the selected membrane system parameters, lay PET or PE membranes at specified intervals, and connect various accessories (carbon dioxide supplementary thin tubes, pump mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com