Method for producing volatile fatty acid through heating and circular anaerobic fermentation of sludge

A technology of sludge anaerobic fermentation and volatile fatty acid, applied in fermentation, biological sludge treatment and other directions, can solve the problems of difficult and efficient acid production, difficult hydrolysis and acidification, low organic matter content, etc., to achieve compact structure and prevent water eutrophication. The effect of high efficiency and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

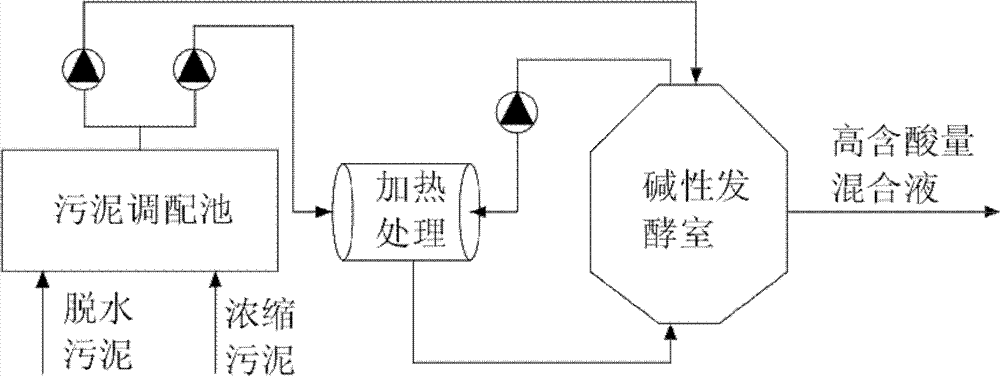

[0024] figure 1 A flowchart showing the method for producing volatile fatty acids by anaerobic fermentation of heated circulating sludge of the present invention.

[0025] Take dewatered sludge (water content 79.23%) and thickened sludge (water content 98.12%) from a sewage treatment plant in a certain place to make mixed sludge with water content 98.0% in the sludge blending tank. At this time, its volatile The ratio VS / TS of organic solid concentration to total solid concentration is 65.2%. Pump 10.0L (the corresponding sludge residence time is 3d) into the anaerobic fermentation chamber every day through the sludge pump, wherein the total effective volume of the anaerobic fermentation chamber is 30L, and the pH of the anaerobic fermentation chamber is controlled at 9.0 by adding NaOH ~11.0, and control the temperature at 20°C and the stirring speed at 50rpm. And a bypass is set up on the side of the fermentation chamber to discharge 3L of material per day (reflux ratio is...

Embodiment 2

[0030] Take dewatered sludge (water content 80.31%) and thickened sludge (water content 98.03%) from a sewage treatment plant in a certain place to make mixed sludge with water content 92.0% in the sludge blending tank. At this time, its volatile The ratio VS / TS of organic solid concentration to total solid concentration is 52.3%. Pump 10.0L (corresponding sludge residence time is 5d) into the anaerobic fermentation chamber every day through the sludge pump, wherein the total effective volume of the anaerobic fermentation chamber is 50L, and the pH of the anaerobic fermentation chamber is controlled at 9.0 by adding quicklime ~11.0, and control the temperature at 36°C and the stirring speed at 100rpm. And a bypass is set on the side of the fermentation chamber to discharge 10 L of material per day (reflux ratio is 20%) to the heating pretreatment device, and then circulate and drop into the anaerobic fermentation chamber after heating at 110 degrees for 30 minutes. At the sam...

Embodiment 3

[0035] Take dewatered sludge (water content 82.11%) and thickened sludge (water content 97.89%) from a sewage treatment plant in a certain place to make mixed sludge with water content 88.0% in the sludge blending tank. At this time, its volatile The ratio VS / TS of organic solid concentration to total solid concentration is 34.3%. Pump 2.5L (corresponding sludge residence time is 8d) into the anaerobic fermentation chamber every day through the sludge pump, wherein the total effective volume of the anaerobic fermentation chamber is 20L, and the pH of the anaerobic fermentation chamber is controlled at 9.0 by adding NaOH ~11.0, and control the temperature at 55°C and the stirring speed at 150rpm. And a bypass is set up on the side of the fermentation chamber to discharge 1 L of material per day (reflux ratio is 5%) to the pretreatment device, and then circulate and drop into the anaerobic fermentation chamber after heating at 100 degrees for 30 minutes. At the same time, 2.5L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com