Manufacturing process for heat storage insulation cotton

A manufacturing process and technology of thermal insulation cotton, applied in the field of textile fabrics, can solve the problems of sacrificing breathability, unfavorable thermal performance and keeping warm for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

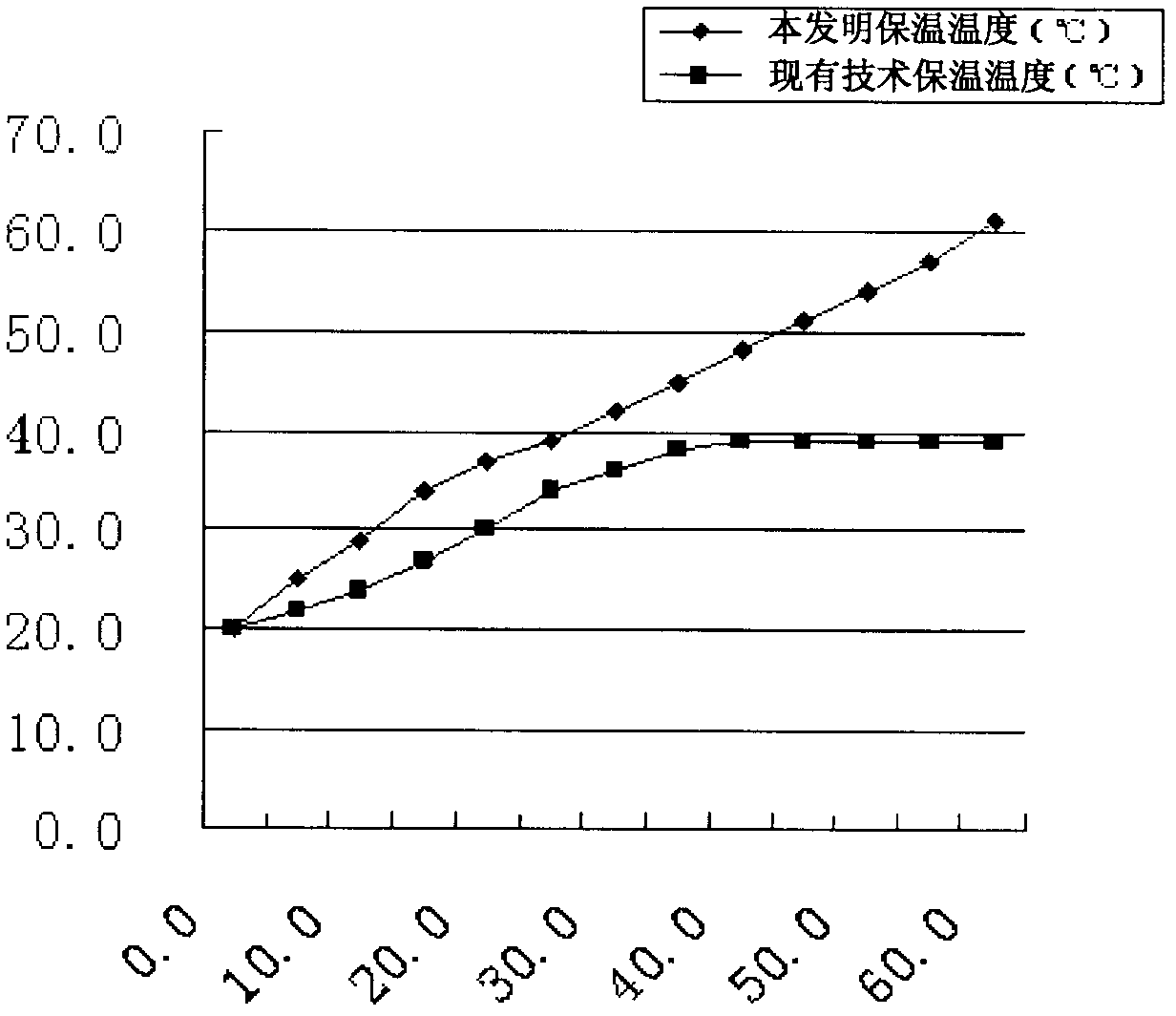

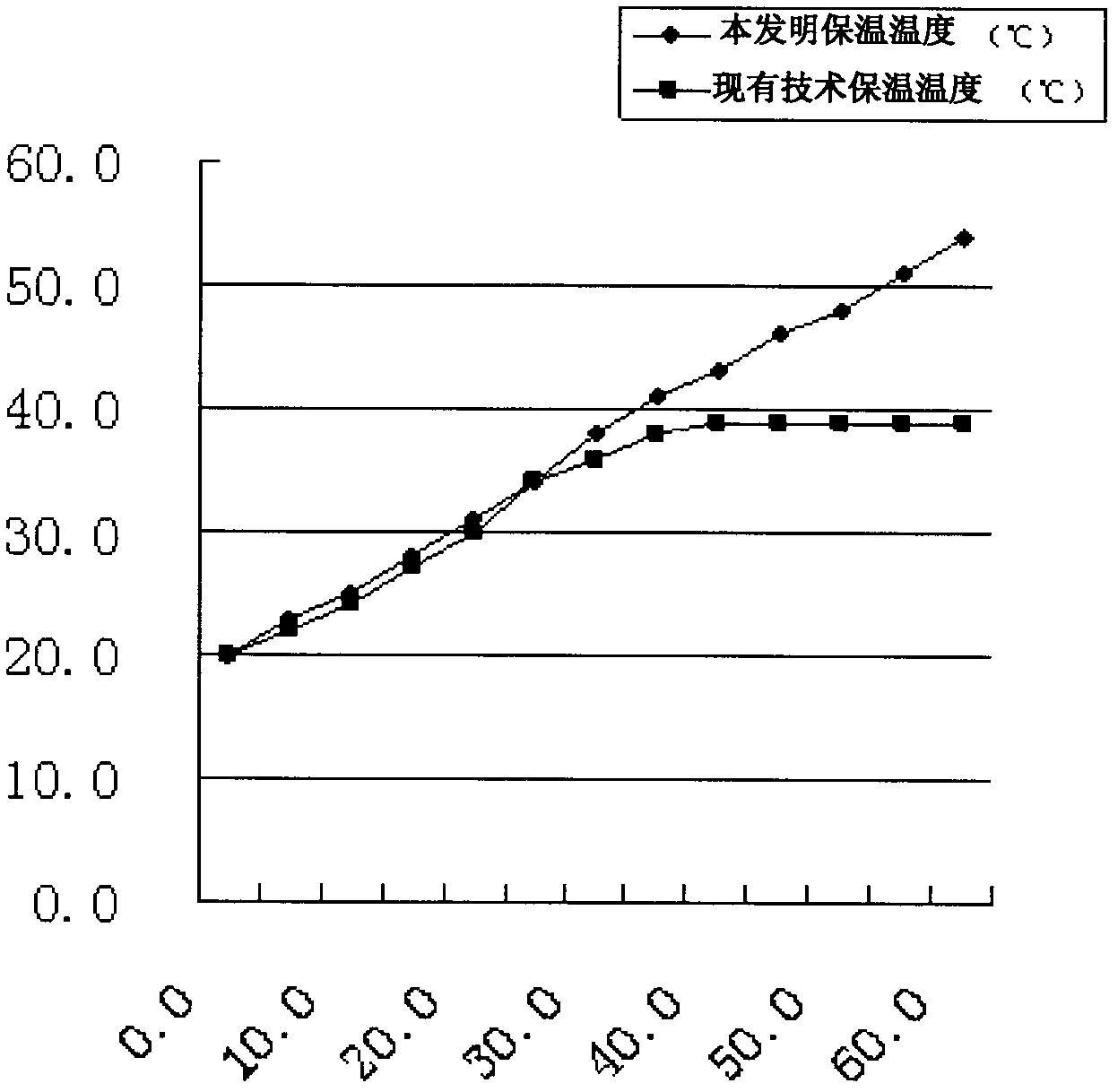

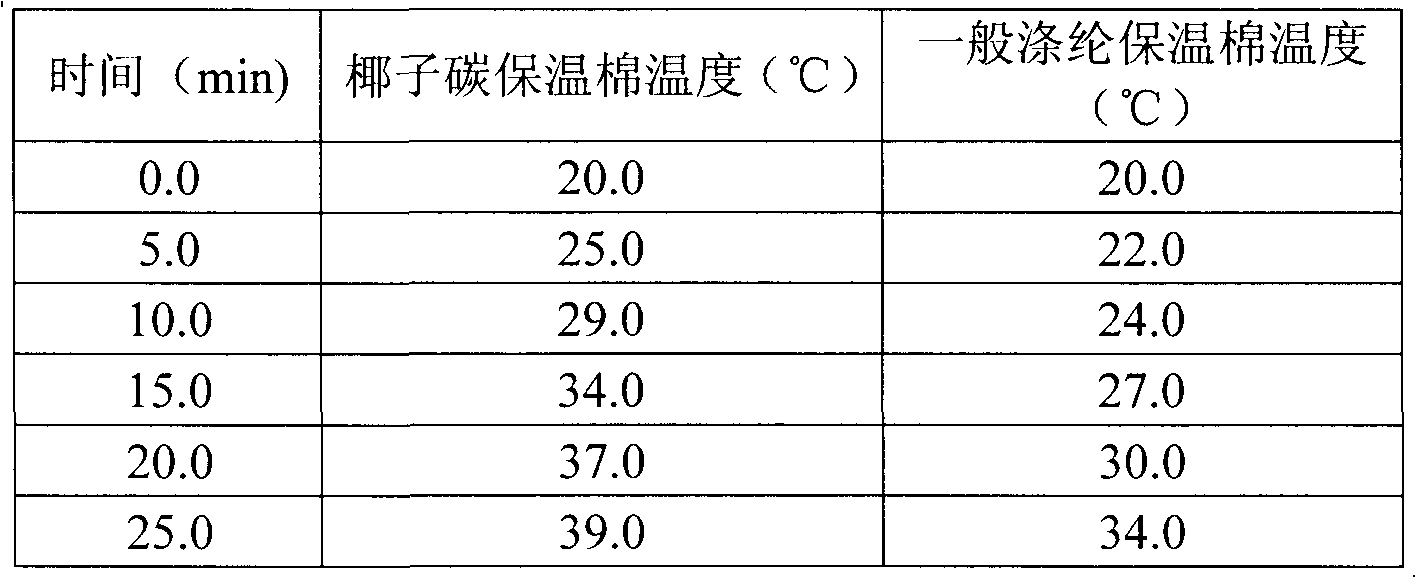

[0030] Embodiment 1-3: A manufacturing process for heat storage and heat preservation cotton, the heat storage and heat preservation cotton is obtained through the following process, which process includes the following steps:

[0031] Step 1, heating the fibers of the coconut shell to 480-520°C for carbonization treatment to obtain carbonized fibers, the carbonization temperature is 480°C in Example 1, 500°C in Example 1, and 520°C in Example 1; then carbonize Coconut carbon micropowder is obtained by high-temperature activation treatment at 800-1000°C on fiber, which can produce activated carbon with developed microporous structure and huge specific surface area. , embodiment 1 is 800 ℃;

[0032] Step 2, the polyester chip, silane coupling agent, zinc stearate as surfactant and liquid wax as dispersant are uniformly mixed at high temperature according to the mass ratio of 100:0.39~0.41:2.7~2.8:6.8~7 Form molten polyester; zinc stearate: surfactant, reduce the surface tensio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com