External wall insulation and decoration integrated plate with sand grain decoration for outer wall surfaces and production line thereof

An external wall insulation and sand pattern technology, which is applied in manufacturing tools, transportation and packaging, construction, etc., can solve the problems of poor construction safety, poor fire resistance of thermal insulation materials, easy cracking of walls, etc. Save processes and man-hours, and ensure the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiments:

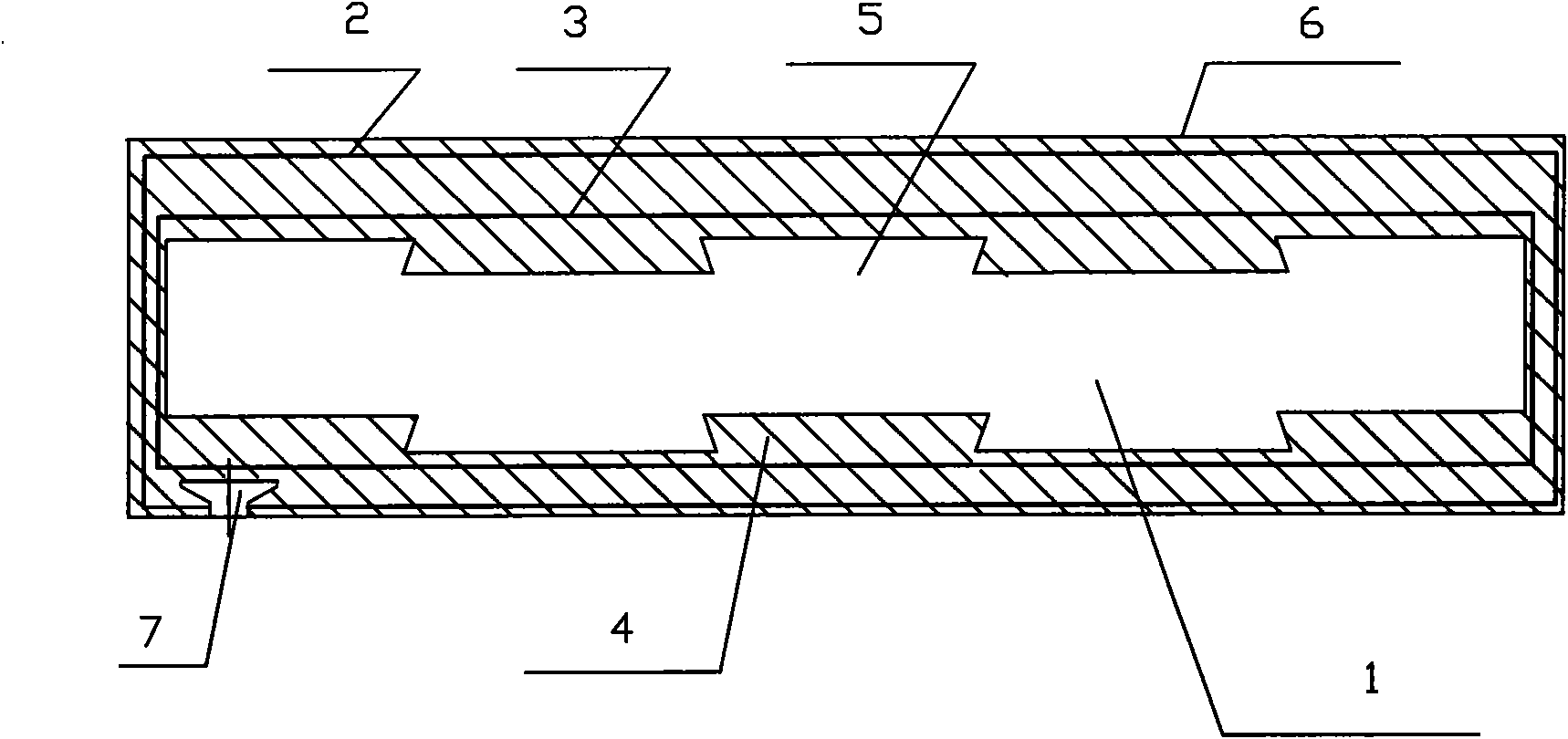

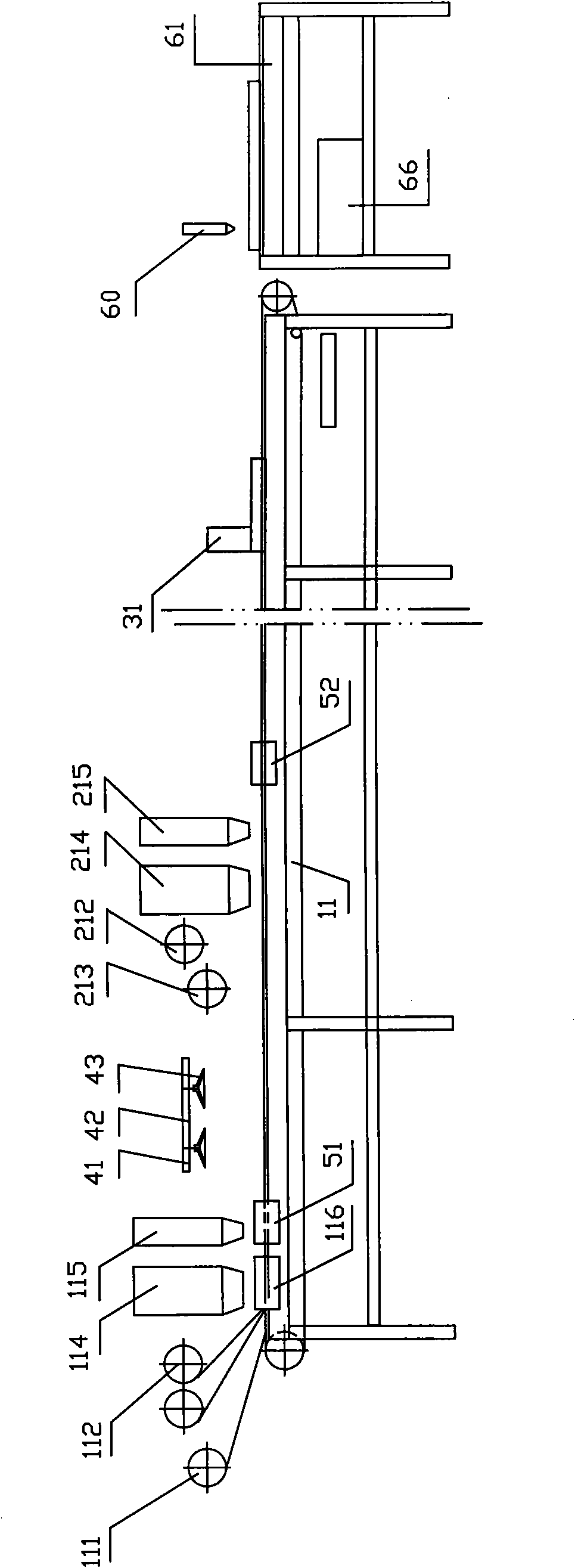

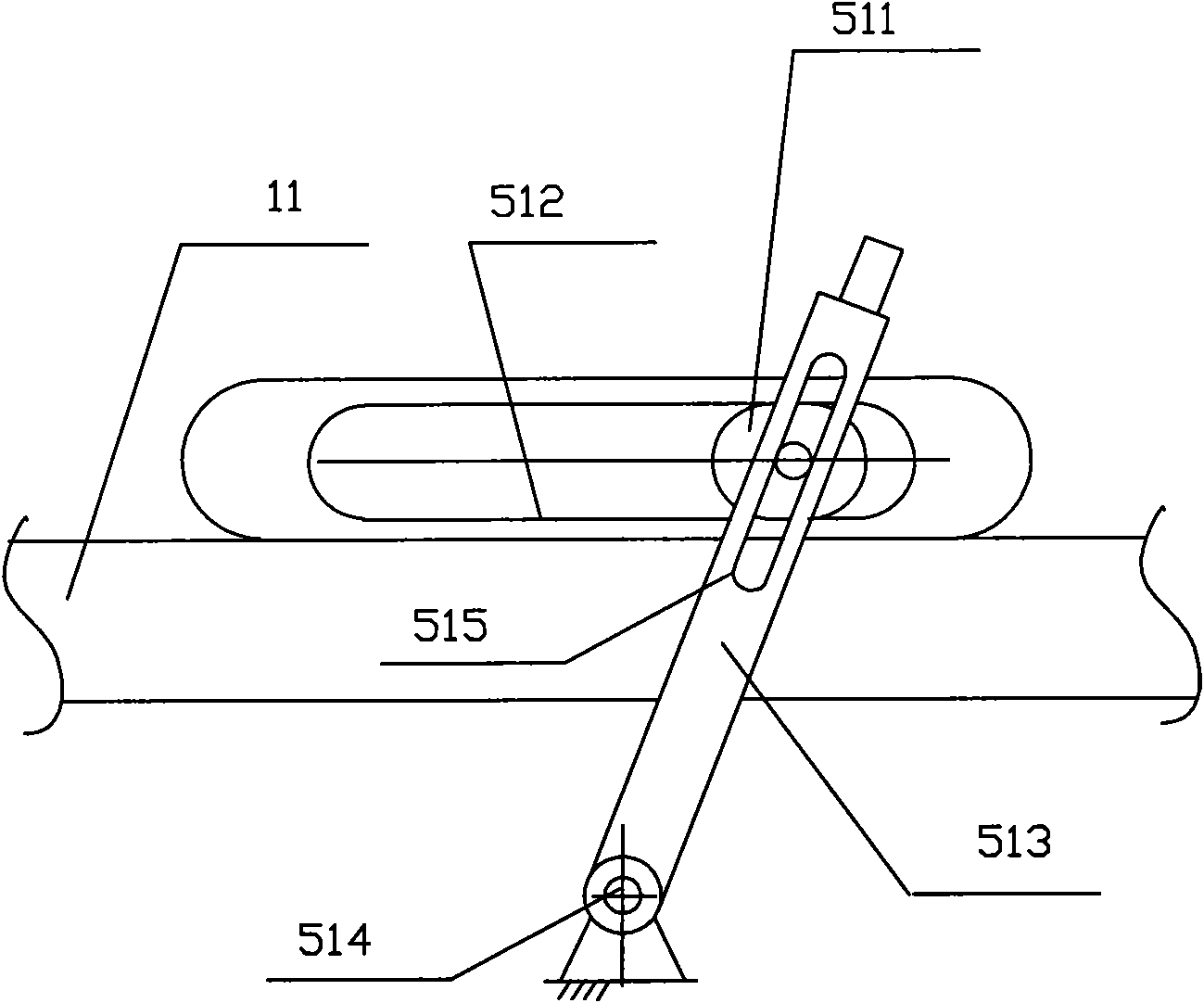

[0023] figure 1 It is a schematic structural cross-sectional view of a product according to an embodiment of the present invention. As shown in the figure, an integrated external wall insulation and decoration board with sand-grained decorative external walls includes: an intermediate thermal insulation layer 1, and an inner glass fiber mesh cloth 2 wrapped around the periphery of the intermediate thermal insulation layer The rectangular frame formed by the glass fiber mesh cloth 3 and the concrete layer 4 of cement slurry and glass fiber chopped strands filled inside and outside the frame; the inner surface of the upper layer of the middle insulation layer 1 and the concrete layer 4, and the inner surface of the lower layer of the concrete layer The joint surface of the surface is convex and concave 5 connecting. The convex and concave connection is mainly to expand the bonding area b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com