Electrochemical method for detecting trace trivalent inorganic arsenic by using mercaptoethylamine modified electrode

A mercaptoethylamine and modified electrode technology, applied in the field of electrochemical detection, can solve the problems of complex electrochemical methods, poor anti-interference ability, long detection time, etc., to avoid electrochemical polarization process, strong anti-interference ability, The effect of short detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

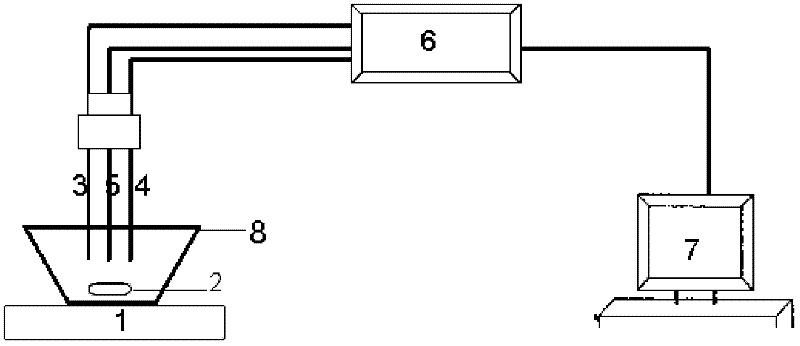

[0032] Step 1: Using as figure 1 In the three-electrode electrochemical system shown, the gold electrodes were polished to a "mirror surface" with suede with 1.0 μm and 0.3 μm alumina suspensions respectively, and were cleaned by ethanol and secondary water ultrasonically before use;

[0033] Step 2: Put the treated gold electrode obtained in step 1 into 10mM mercaptoethylamine solution, soak for 1 hour, fix mercaptoethylamine on the surface of the gold electrode through the action of Au-S bond, and then wash the electrode with secondary water Rinse to obtain a gold electrode modified with mercaptoethylamine;

[0034] Step 3: Put a magnetic stirrer 2 in the electrochemical detection cell 8, place it on the magnetic stirrer 1, use the gold electrode modified with mercaptoethylamine obtained in step 2 as the working electrode 3, and silver-silver chloride as the reference For the counter electrode 4, platinum is co-inserted for the counter electrode 5 respectively containing 0....

Embodiment 2

[0039] Step 1: Using as figure 1 In the three-electrode electrochemical system shown, the gold electrodes were polished to a "mirror surface" with suede with 1.0 μm and 0.3 μm alumina suspensions respectively, and were cleaned by ethanol and secondary water ultrasonically before use;

[0040] Step 2: Put the treated gold electrode obtained in step 1 into 10mM mercaptoethylamine solution, soak for 1 hour, fix mercaptoethylamine on the surface of the gold electrode through the action of Au-S bond, and then wash the electrode with secondary water Rinse to obtain a gold electrode modified with mercaptoethylamine;

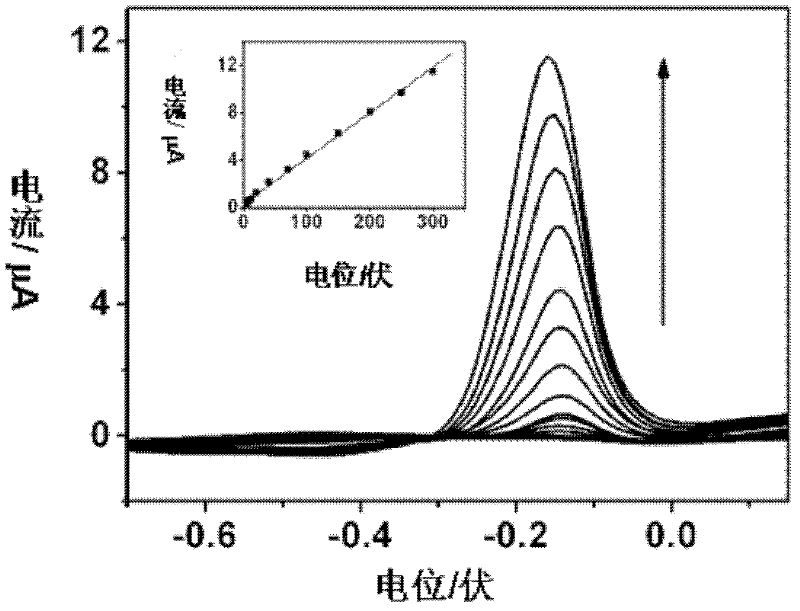

[0041] Step 3: Put a magnetic stirrer 2 in the electrochemical detection cell 8, place it on the magnetic stirrer 1, use the gold electrode modified with mercaptoethylamine obtained in step 2 as the working electrode 3, and silver-silver chloride as the reference Compared to electrode 4, platinum is co-inserted for counter electrode 5 containing 100 μgL -1 In the elec...

Embodiment 3

[0049] Step 1: Using as figure 1 In the three-electrode electrochemical system shown, the gold electrodes were polished to a "mirror surface" with suede with 1.0 μm and 0.3 μm alumina suspensions respectively, and were cleaned by ethanol and secondary water ultrasonically before use;

[0050] Step 2: Put the treated gold electrode obtained in step 1 into 10mM mercaptoethylamine solution, soak for 1 hour, fix mercaptoethylamine on the surface of the gold electrode through the action of Au-S bond, and then wash the electrode with secondary water Rinse to obtain a gold electrode modified with mercaptoethylamine;

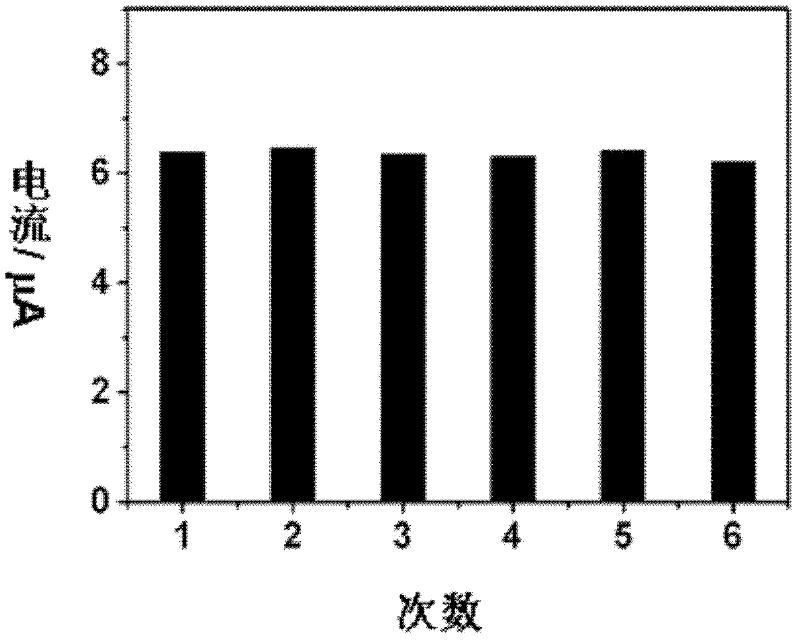

[0051] Step 3: Put a magnetic stirrer 2 in the electrochemical detection cell 8, place it on the magnetic stirrer 1, use the gold electrode modified with mercaptoethylamine obtained in step 2 as the working electrode 3, and silver-silver chloride as the reference Add 50 μgL of platinum for the common insertion of the counter electrode 4 and the counter electrode 5 -1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com