Self-assembly preparation method for floating gate layer of silicon nitride dielectric film with embedded metal tungsten quantum dots

A technology of tungsten quantum and silicon nitride, which is applied in the field of self-assembly to prepare the floating gate layer of silicon nitride dielectric film embedded with metal tungsten quantum dots, which can solve the constraints of miniaturization, quantum dot density and size distribution, and the uneven electrical performance of memory cells etc. to achieve the effects of small size, anti-oxidation and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

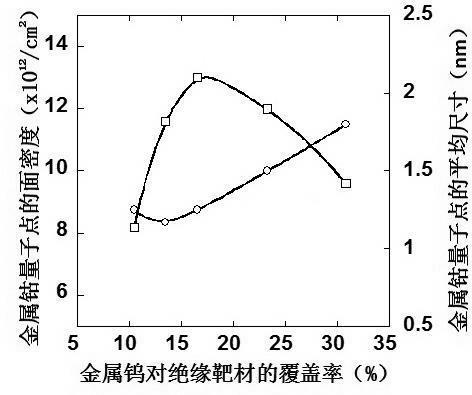

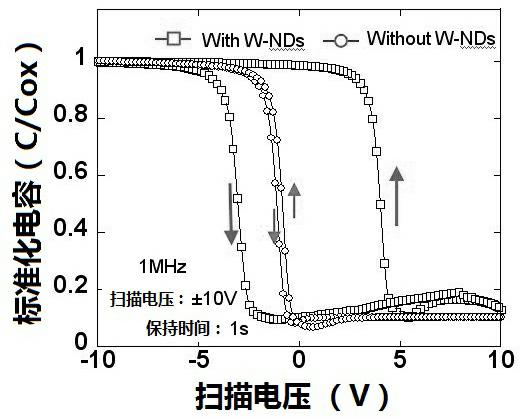

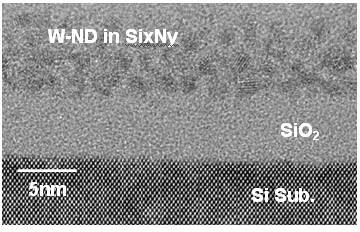

[0025] The target for magnetron sputtering is a 2-inch silicon nitride target, on which 5mmx5mmx1.5mm small metal tungsten pieces are evenly placed, and the coverage of the metal tungsten small pieces on the silicon nitride target is adjusted, and the range is 10%~ 30%. After standard cleaning of P-type (100) silicon wafers, silicon dioxide is grown by thermal oxidation with a thickness of about 5nm. Put the above-mentioned silicon wafer into the magnetron sputtering reaction chamber. The sputtering conditions are: the vacuum degree of the chamber body is 4x10 -6 Pa, the argon flow rate is 8sccm, the RF power applied to the target is 100W, the working pressure is 0.08Pa, the substrate is not heated, the substrate speed is 75rpm / min, and the sputtering film thickness is 5nm. The thin film embedded with metal tungsten quantum dots was vacuum annealed in situ in the sputtering chamber at a temperature of 800 degrees for 1 hour. figure 1 The graph showing the relationship betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com