Process for anisotropic etching of semiconductors

An anisotropic, semi-conductive technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of low uniformity and achieve the effect of improving the etching profile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

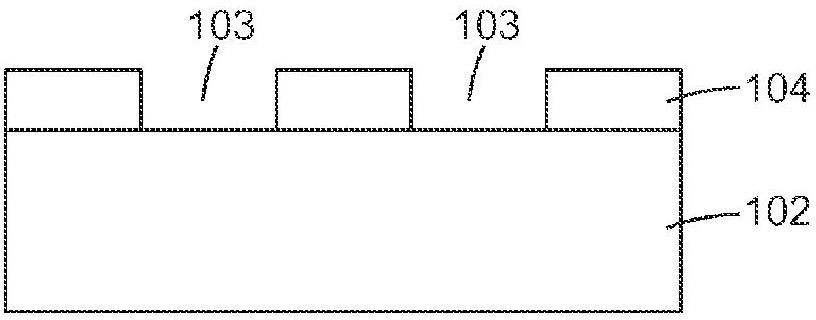

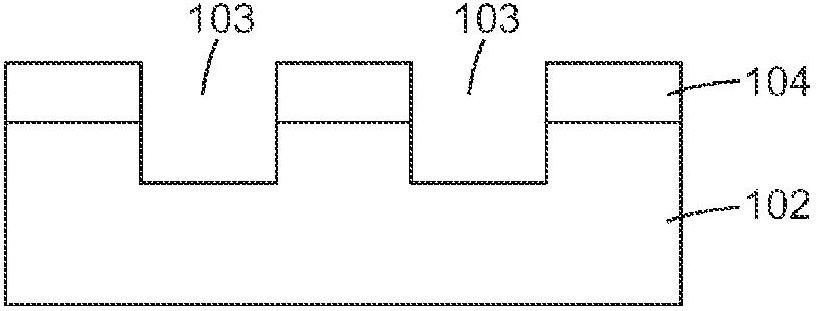

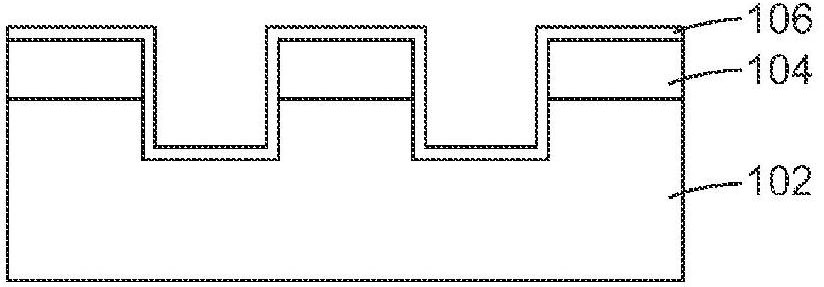

[0033] The II-VI semiconductor color conversion layer structure based on MgCdZnSe alloy was grown by molecular beam epitaxy on InP substrate. Structural details of color converting layers can be found, for example, in US Patent No. 7,402,831 (Miller et al.). The structure of the color conversion layer is schematically shown in figure 2 , the thickness and composition of its layers are shown in Table I below. figure 2 is a schematic diagram of the color conversion layer 200 , which includes a top window 202 , an absorber 204 , and a graded composition layer 206 that gradually changes from the composition of the top window 202 to the composition of the absorber 204 .

[0034] Table I

[0035] Composition of the color conversion layer structure

[0036] layer

[0037] A raised photoresist pattern was generated on the II-VI semiconductor structures described above using a negative-tone photoresist (NR1-1000P from Futurrex, Franklin, NJ) and conventional contact...

example 1

[0040] Example 1 - Combined Ar etch and CHF 3 passivation

[0041] A sample of Comparative Example 1, also covered by a photoresist mask, was etched as follows:

[0042] a) Under the same conditions listed in Table I, the sample was etched by Ar sputtering for 30 seconds for the first time.

[0043] b) Turn off the plasma and argon supply, let trifluoromethane (CHF 3 ) into the process chamber at a rate of 40 sccm for 30 seconds.

[0044] c) Restore the plasma and use 5-40sccm CHF 3 , 20-200 watts of Rf power, 700-2000 watts of inductively coupled plasma power, a pressure of 4-30 mTorr and an etching time of 5 seconds for plasma polymerization of trifluoromethane.

[0045] d) Shut off the trifluoromethane supply and let Ar gas flow into the chamber at 40 sccm for 30 seconds.

[0046] e) Repeat steps a) to d) for a total of 8 times.

[0047] Figure 4 are scanning electron micrographs of CdMgZnSe crystals using processes a) to e). It can be observed that an etch p...

example 2

[0049] A sample from Comparative Example 1 overlaid by a photoresist mask made with NR9-300PY negative photoresist (from Futurrex, Franklin, NJ) was etched using the procedure of Example 1, except that Ar etch for 60 seconds and steps a) to d) were repeated 6 times. Figure 5 is a scanning electron micrograph of the resulting structure and shows deep etching of II-VI material with wall angles of almost 90 degrees. It is calculated that the etching rate of the semiconductor material is 341 nm / min, while the etching rate of the photoresist material is 126 nm / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com